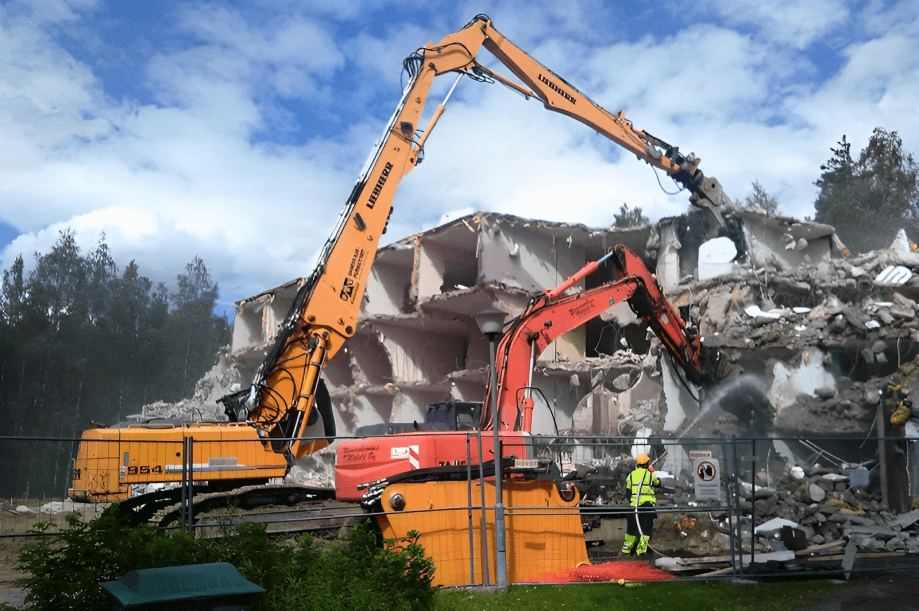

The crushing concrete enables effective recycling and reuse of concrete waste

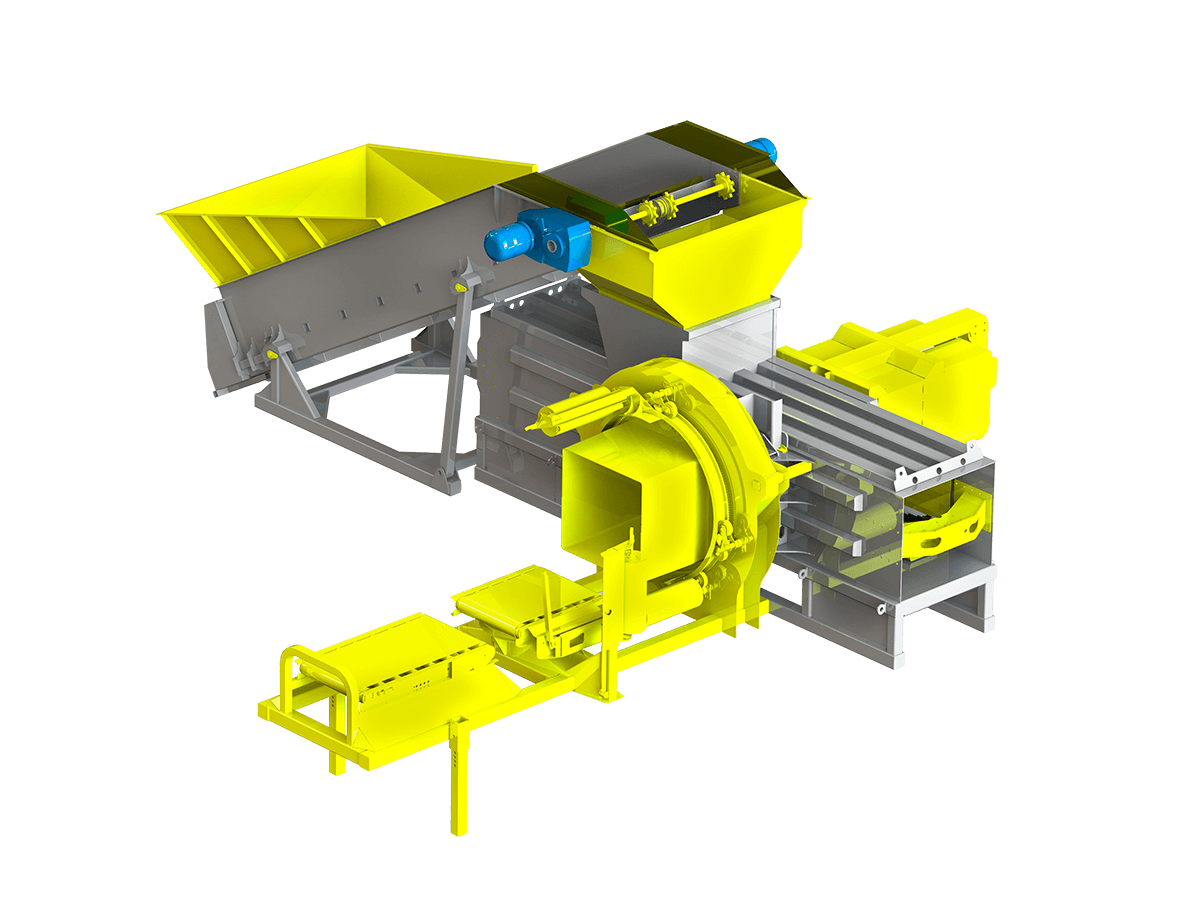

By breaking down concrete waste into smaller, manageable pieces, we pave the way for its efficient recycling and subsequent reuse. This process typically involves the utilization of an impact crusher or, for smaller volumes, a crushing bucket, both designed to achieve the optimal size of crushed concrete. Following the crushing process, the material undergoes a thorough separation from impurities, including steel reinforcements and other foreign substances, ensuring a pure recycled product.

The benefits of reusing crushed concrete are multifaceted. Primarily, it significantly reduces the demand for new concrete, thereby preserving natural resources and minimizing the environmental footprint of construction activities. Furthermore, the practice plays a crucial role in diminishing the volume of concrete waste that otherwise contributes to the escalating issue of landfill overuse.

Incorporating concrete crushing into the construction lifecycle not only aligns with sustainable construction methodologies but also exemplifies the principles of a circular economy within the industry. By fostering the efficient recycling and reuse of concrete waste, we encourage a more responsible use of resources and promote environmental stewardship. This approach not only benefits the planet but also offers a cost-effective solution for the construction sector, advocating for a greener, more sustainable future in building and infrastructure development.

Solutions for concrete crushing

Equipment for crushing concrete – Vipermetal particularly recommends these products for concrete crushing

Vipermetal, a leading brand in the construction industry, highly recommends its range of specialized products for the effective crushing of concrete and related materials. Designed to meet the rigorous demands of concrete demolition and recycling, Vipermetal’s advanced crushing solutions are engineered for peak efficiency and durability.

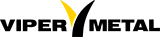

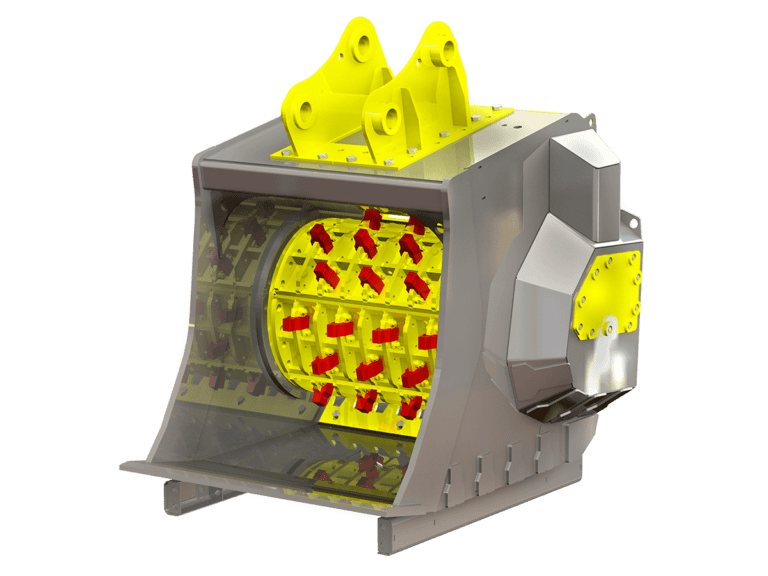

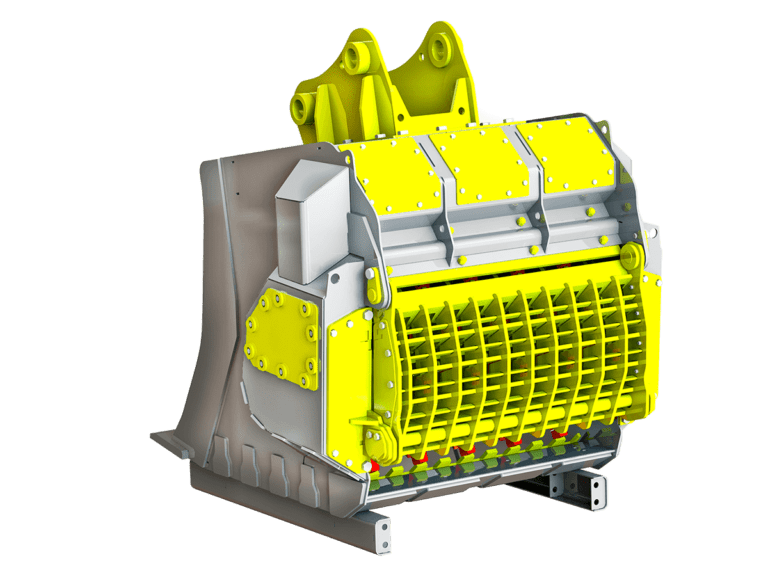

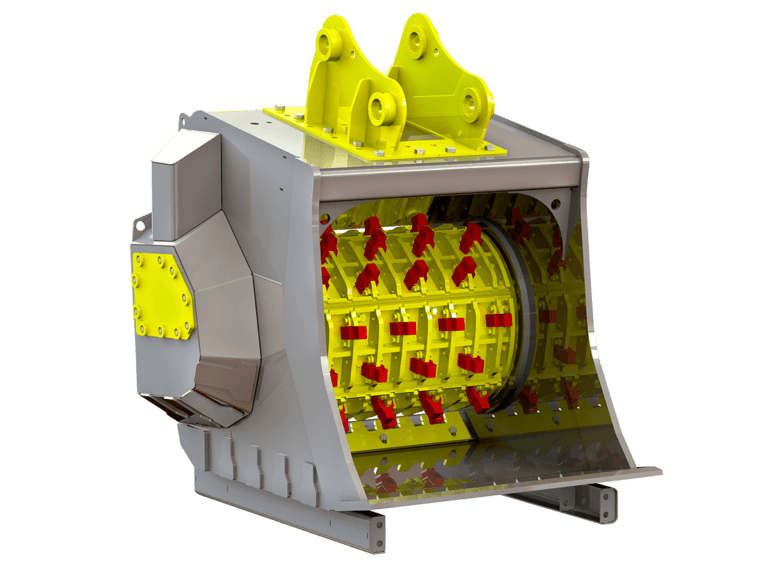

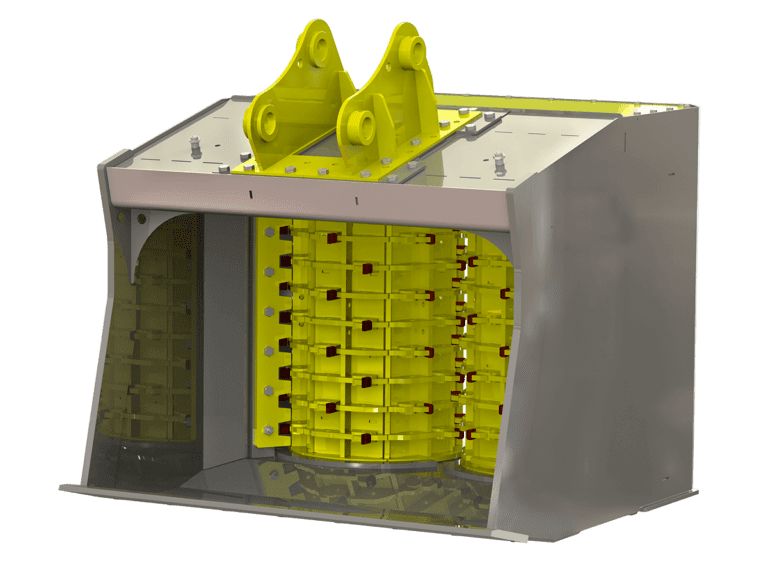

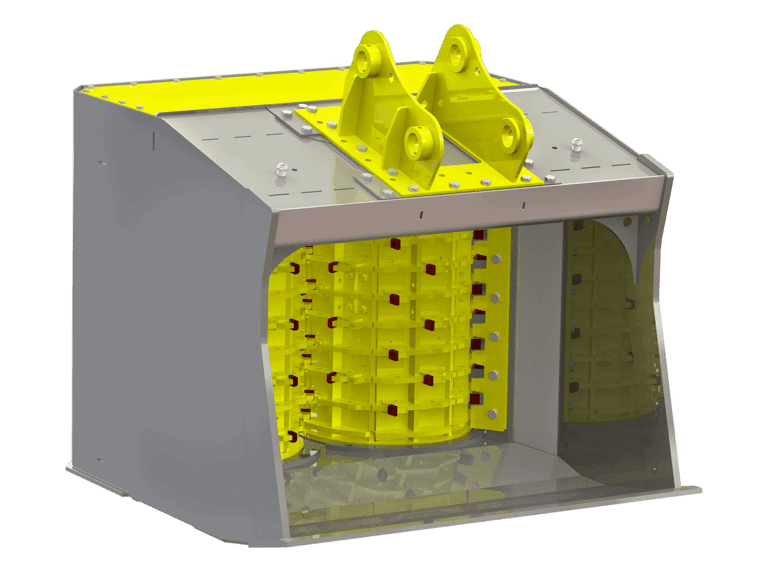

Viper Crusher VPCH-21

Excavators 22000-32000

VPCH-21 is a unique drum crusher bucket. Efficient in crushing demolition materials. Crushes effectively, including concrete, asphalt, and bricks without the risk of clogging.

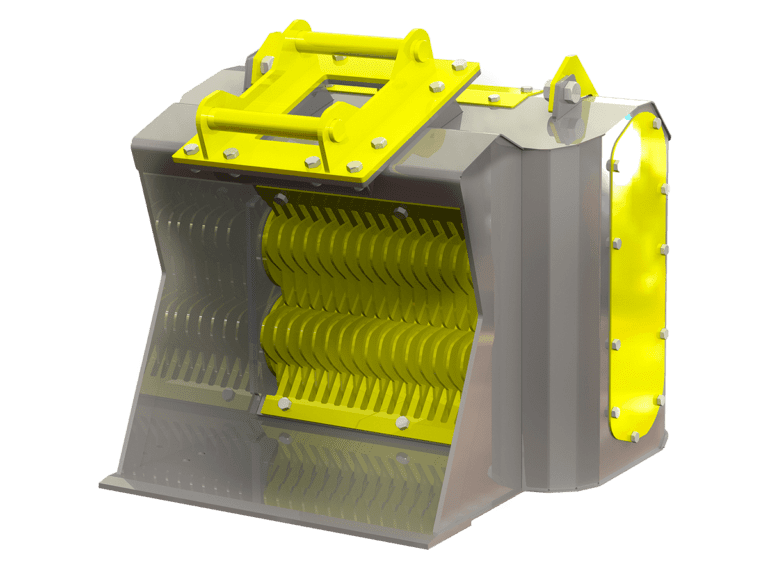

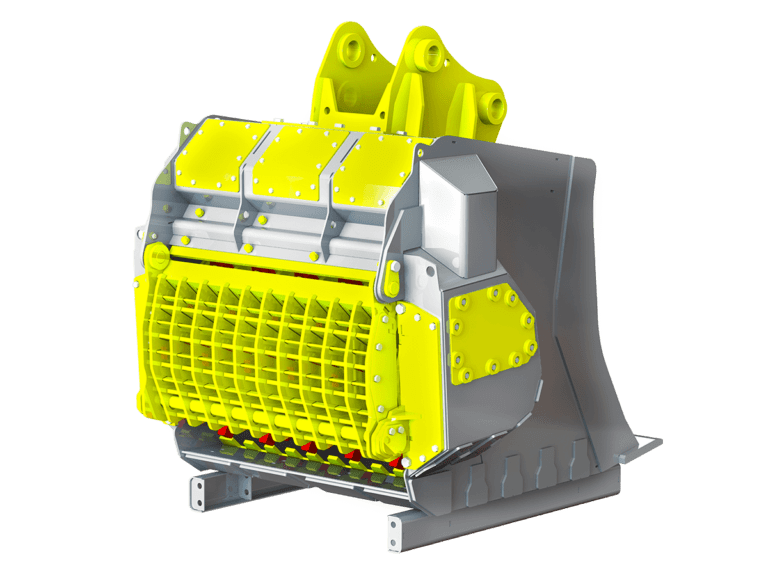

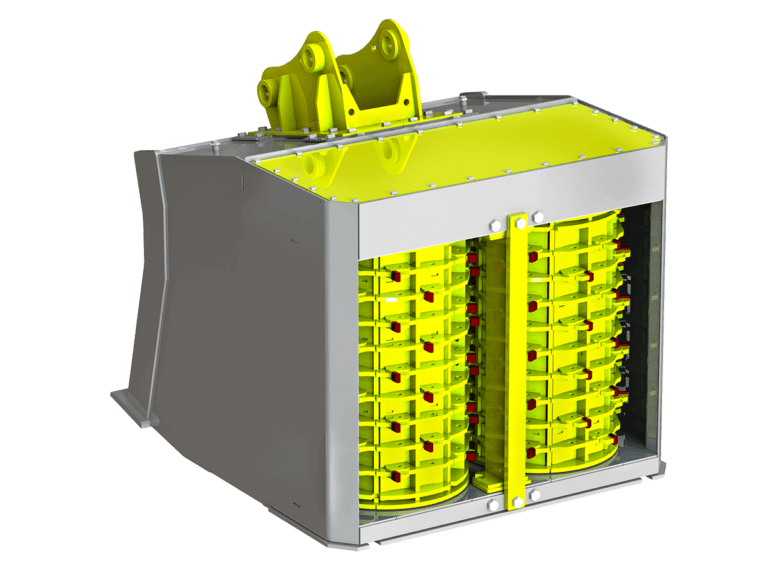

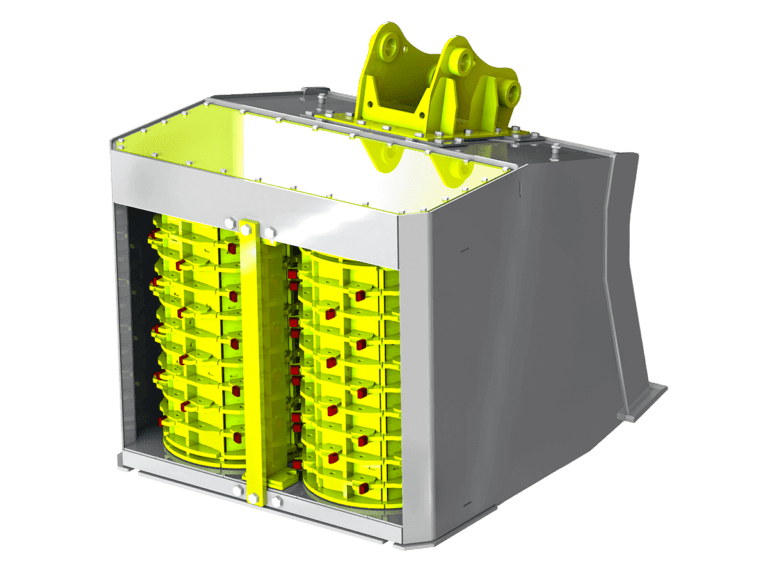

Read moreViper Crusher VPCV-22

Excavators 28000-40000

VPCV-22 is a modern, dual-drum, non-clogging crushing bucket designed for larger excavators. It’s commonly used, particularly in demolition sites, for the versatile crushing of concrete, asphalt, and mixed materials.

Read moreVideo

Watch a video of crushing concrete

Dive into the world of efficient concrete recycling with our exclusive video showcasing the VPCH-21 crusher bucket. This innovative model stands out for its ability to effortlessly crush concrete, asphalt, and bricks, all while avoiding the common problem of clogging. Witness the VPCH-21 in action, a drum bucket crusher designed for precision and durability, revolutionizing the way we handle construction waste. Join us to see the future of sustainable construction and demolition practices through the lens of cutting-edge technology.

Concrete crushing equipment

Vipermetal’s concrete crushing equipment for enhanced productivity

With an emphasis on innovation and quality, Vipermetal’s products stand out for their ability to transform concrete rubble into reusable aggregates with precision and ease. These tools are specifically tailored to enhance productivity in concrete crushing tasks, making them an ideal choice for professionals seeking reliable and high-performance equipment.

Explore Vipermetal’s comprehensive selection of concrete crushing equipment, crafted to support sustainable construction practices by promoting the recycling and reuse of concrete waste. Discover how Vipermetal’s cutting-edge technology can elevate your projects, ensuring efficient, environmentally friendly, and cost-effective outcomes in concrete processing and recycling endeavors.

Key Features of Vipermetal’s concrete crushing equipment

Vipermetal’s machinery is designed with innovation and quality at the forefront. These machines are engineered to handle the tough demands of crushing concrete, with features that ensure efficiency, reliability, and ease of use. Key features might include:

- High crushing power: Capable of breaking down even the toughest concrete with precision.

- Adjustable output size: Machines often have settings to adjust the size of the crushed material, catering to specific project requirements.

- Durability: Built to withstand the harsh conditions of crushing operations, ensuring long-term reliability.

By utilizing Vipermetal’s concrete crushing equipment, professionals in the construction and demolition sectors can significantly enhance their productivity, achieve cost savings, and contribute to environmental sustainability.

The process of crushing concrete

Crushing concrete with specialized machinery like the ones offered by Vipermetal is a sophisticated process that transforms bulky concrete waste into smaller, reusable aggregates. This process not only supports sustainable construction practices but also significantly reduces the environmental impact of construction waste. Here’s a closer look at how these machines work and the benefits they offer:

Initial concrete breakdown

The process begins with the initial breakdown of concrete rubble into smaller pieces. This is usually done by employing heavy-duty machines like jaw crushers or impact crushers. These machines apply mechanical pressure or impact forces to break the concrete into smaller, manageable chunks.

Secondary crushing

Once the concrete is broken down into smaller pieces, it may go through a secondary crushing process to achieve the desired size of aggregates. This step often involves cone crushers or hammer mills that further reduce the size of the concrete chunks, producing finer aggregates that are suitable for various construction applications.

Screening and separation of concrete waste

After crushing, the aggregate is screened and separated into different size fractions. Screening ensures that only aggregates of specific sizes are used for particular applications, optimizing the quality and performance of the recycled concrete. Additionally, this stage helps to remove any remaining impurities, such as metal reinforcements, dirt, or other foreign materials.

Benefits of using specialized concrete crushing machinery

By converting waste concrete into usable aggregates, these machines promote recycling and reuse, significantly reducing the need for new materials and minimizing waste sent to landfills.

Recycling concrete on-site with these machines can lead to substantial savings in material and transport costs. It eliminates the need to purchase new aggregates and reduces the costs associated with disposing of concrete waste.

Crushed concrete can be reused in various applications, including road base, backfill, or as aggregate in new concrete, providing a versatile solution for construction and demolition waste.

Advanced crushing equipment can produce high-quality aggregates that meet or exceed the performance of traditional materials, ensuring durability and longevity in construction projects.

Would you like more information about our products?

We’d be happy to provide further details about our products and assist you in finding the best possible solution for any situation. Vipermetal’s services and solutions are designed to streamline and enhance your material handling processes. Our goal is to offer you the best service that specifically meets your needs, whether it’s sales, resale, product advice, or exchange machinery. Feel free to contact us!