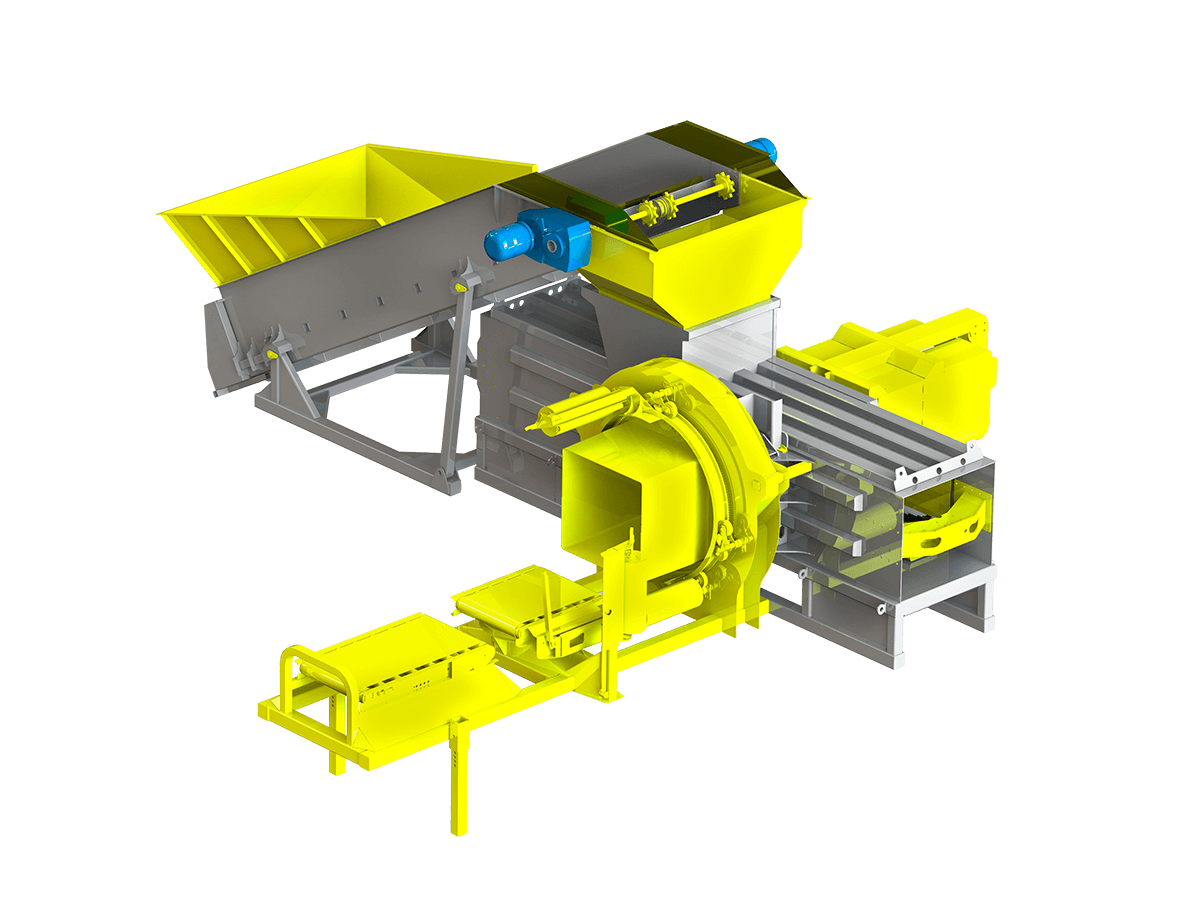

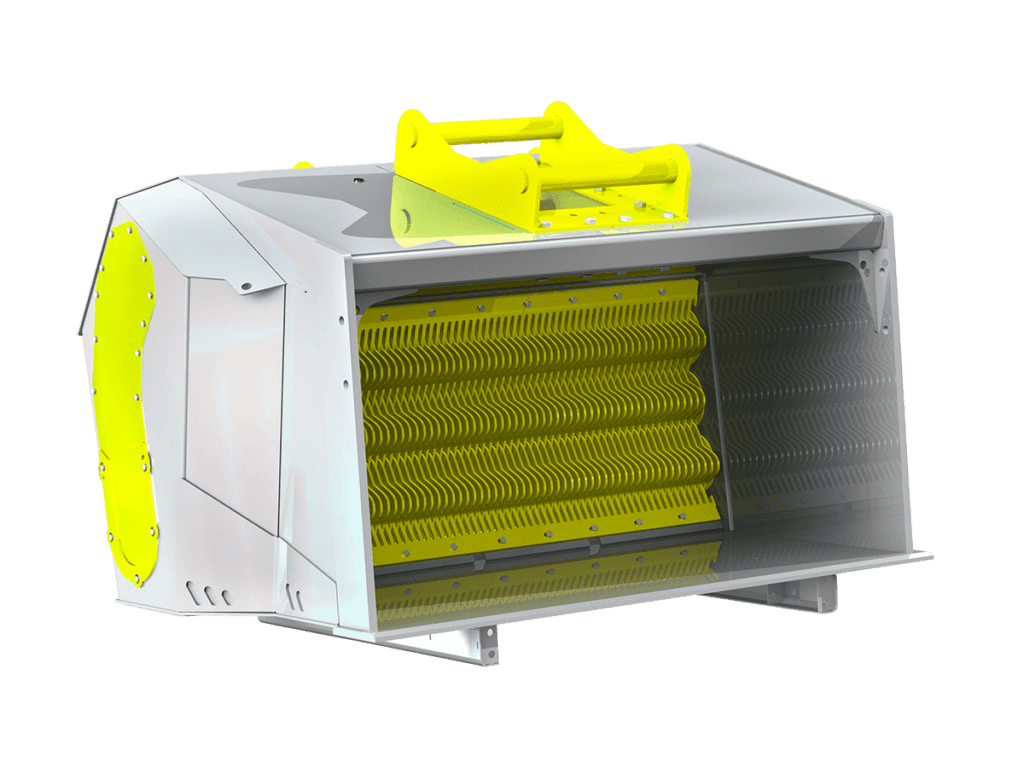

VPH 3-2300 Technical Specifications

Base Machine

- Excavator:

28000-35000 - Wheel loader:

18000-25000

Flow Rate

- Oil Flow min – max:

180-360 /min

Pressure

- Oil Pressure:

210-250

Volume

- ISO/SAE:

3.0-3,4 - Screen area:

2,0

Dimensions

- Height:

1450 - Width:

2650 - Depth:

1650

Weight

- Weight without additional accessories:

2750

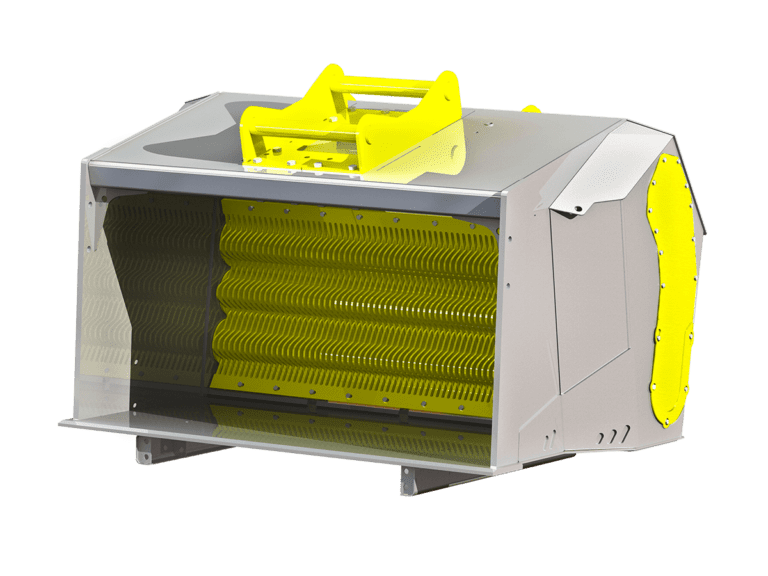

Features

- Lightweight

- Easy and quick to use

- Wide range of blade options

- Ideal for both excavators and wheel loaders

- Cost-effective

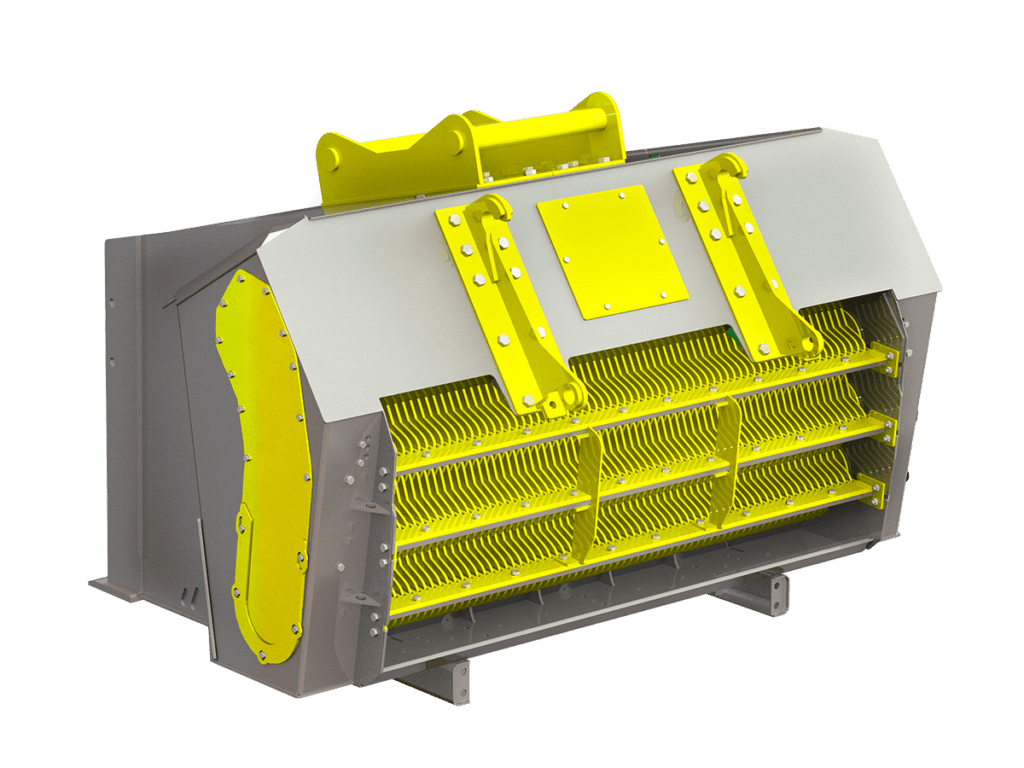

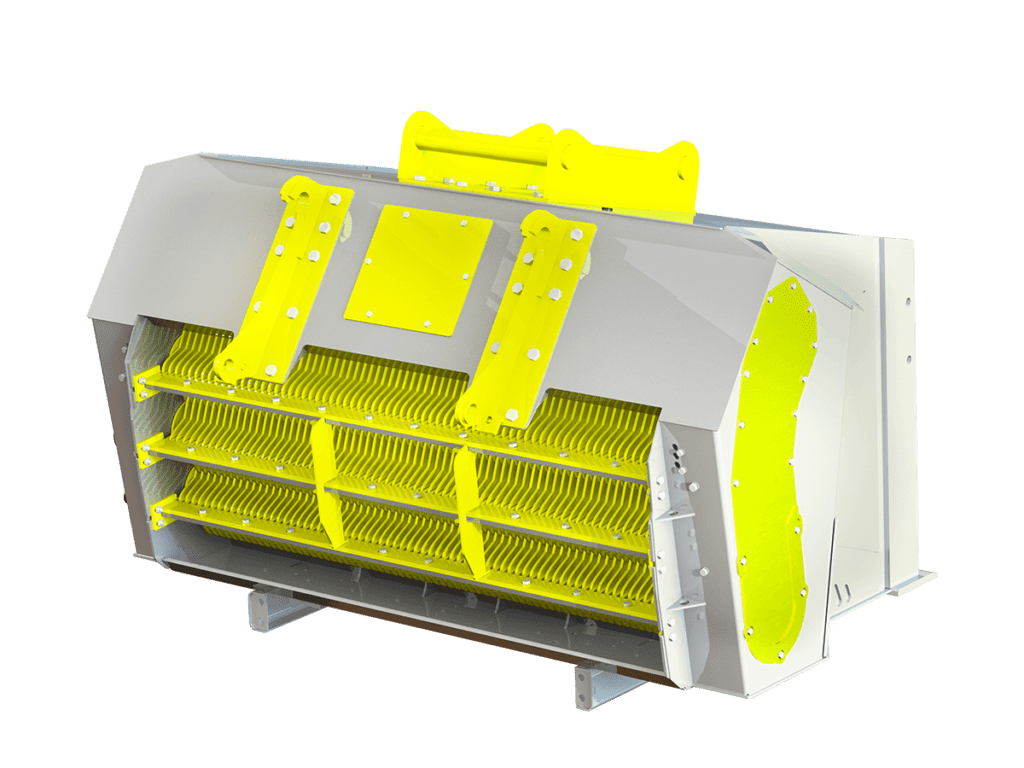

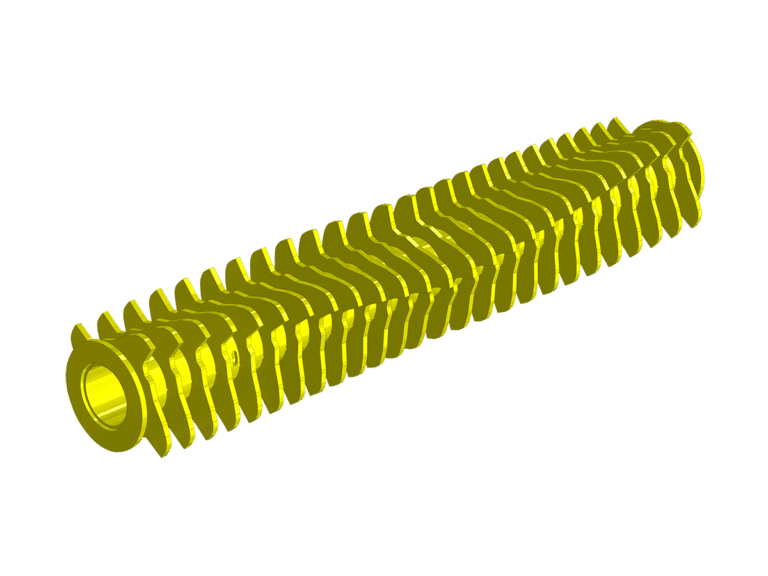

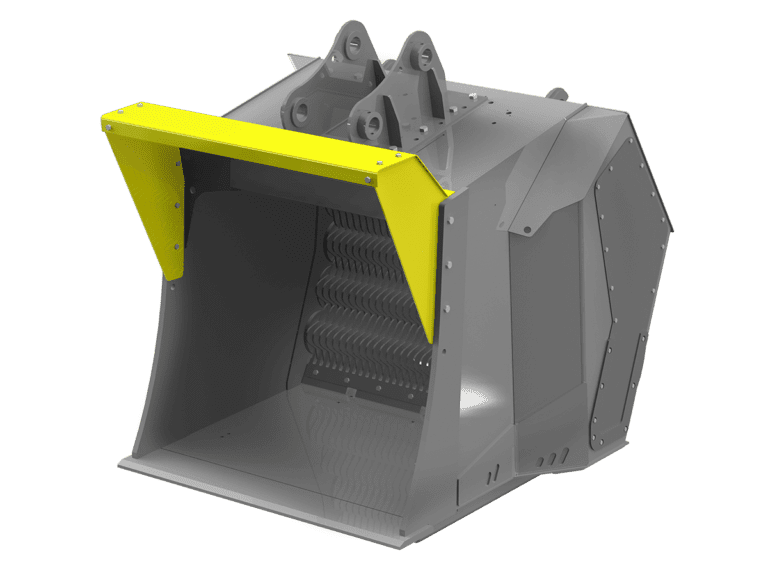

In the design of Vipermetal screening buckets, user needs and comfort have been taken into account. The screening bucket is easy to attach and detach from the machine, saving time and effort on the job site. Additionally, its structural durability and reliability ensure a long lifespan and minimal maintenance requirements

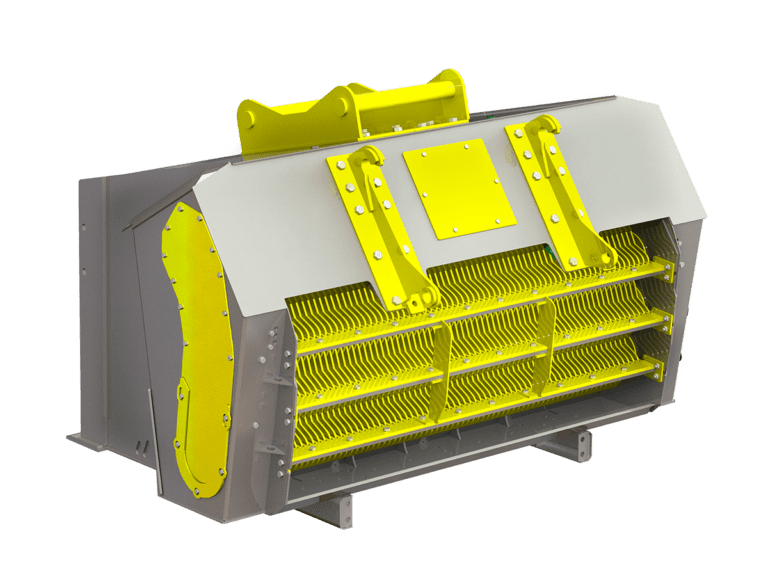

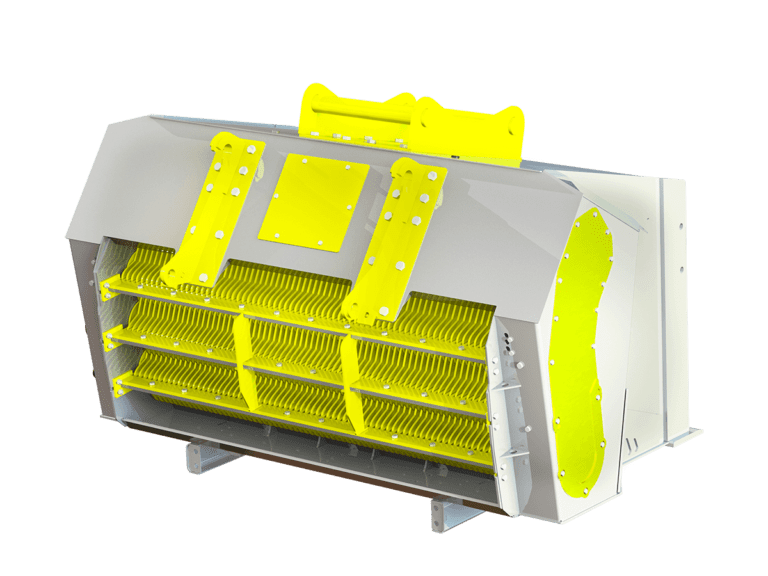

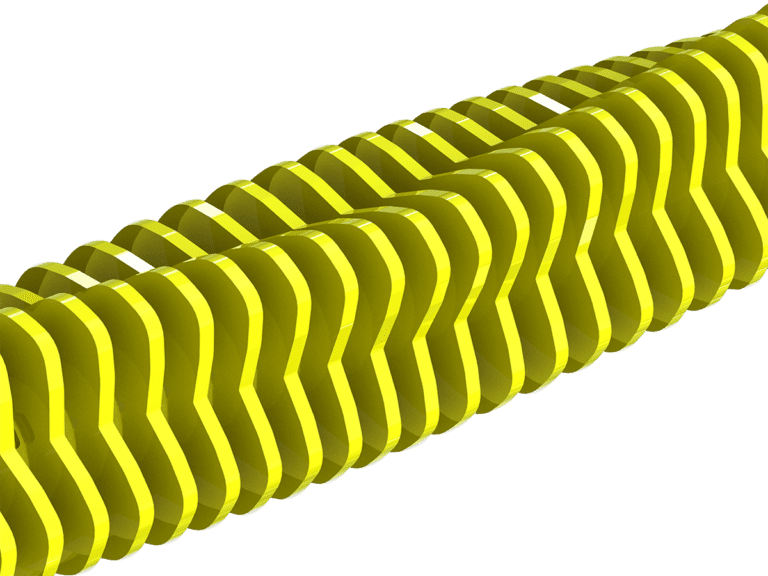

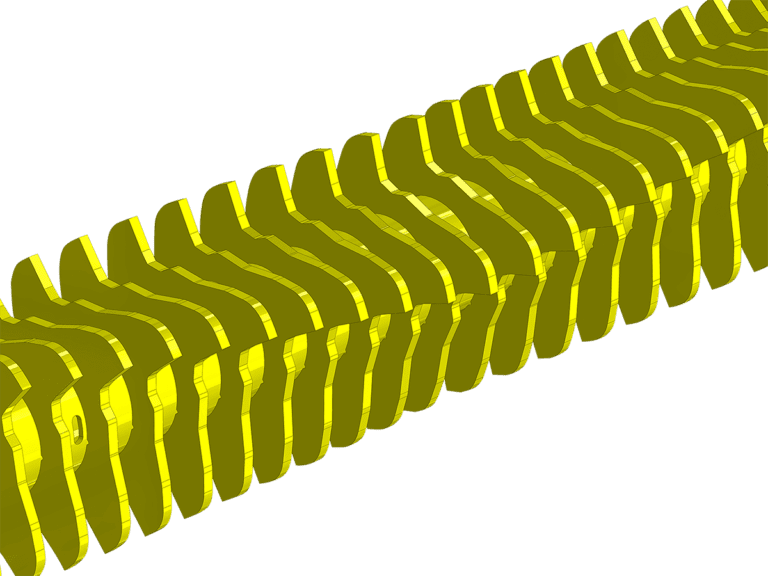

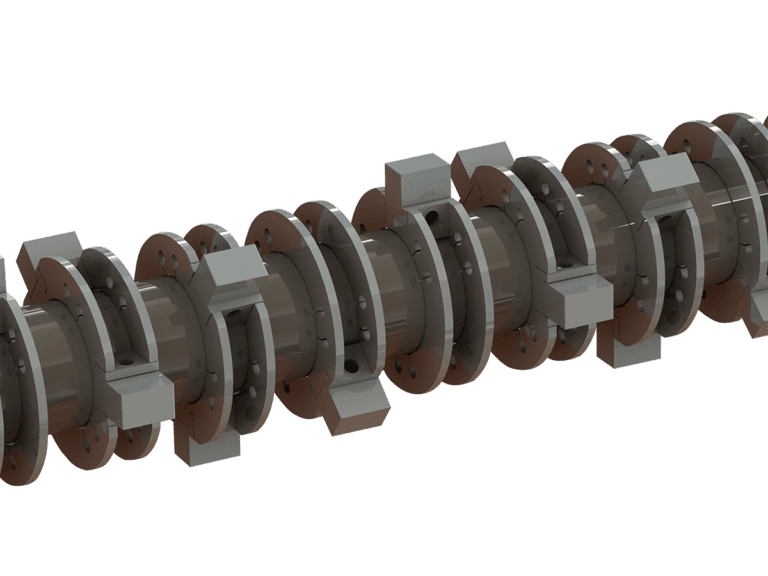

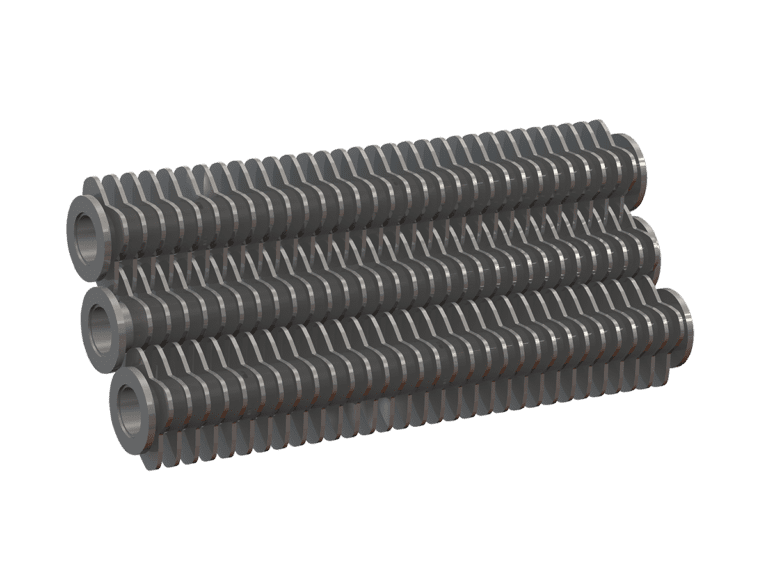

Blade options

Blade options for VPH 3-2300

From our extensive range of blades, there’s always a suitable blade shape available. Blade options cater to screening, light crushing, mixing, bio-aeration, and stabilization. All blade models are available in various spacings, influencing the particle size of the screened material.

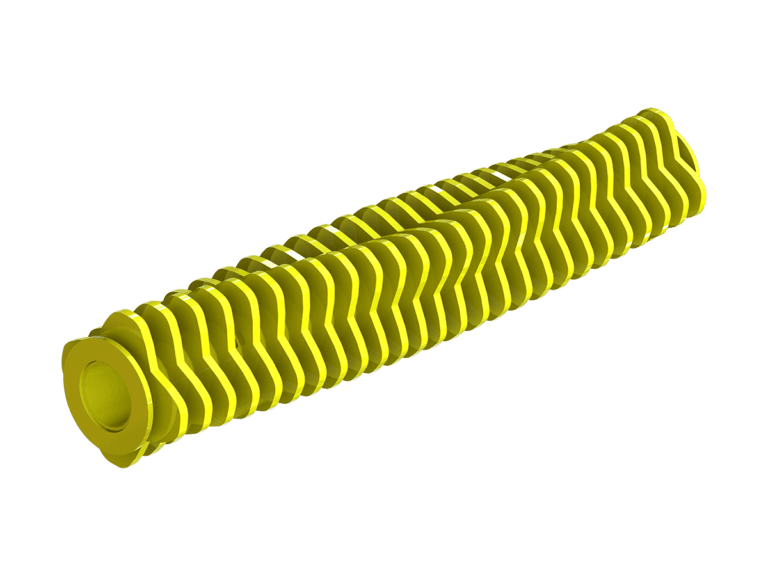

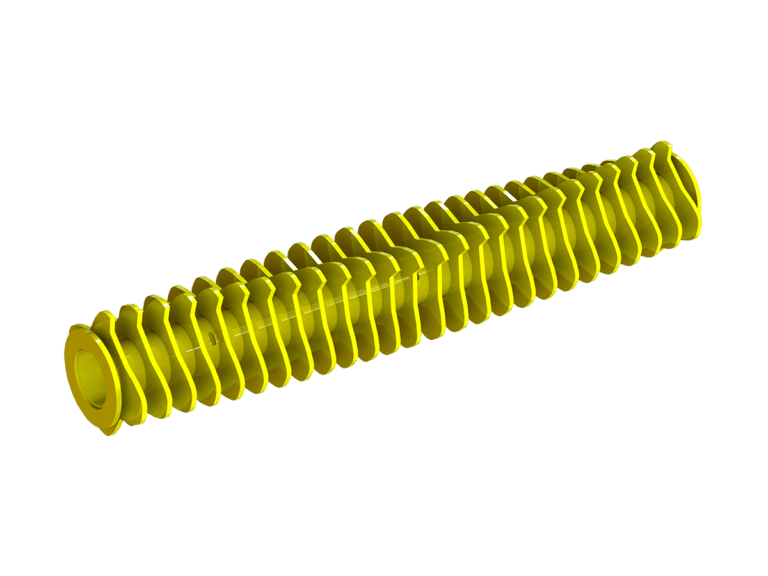

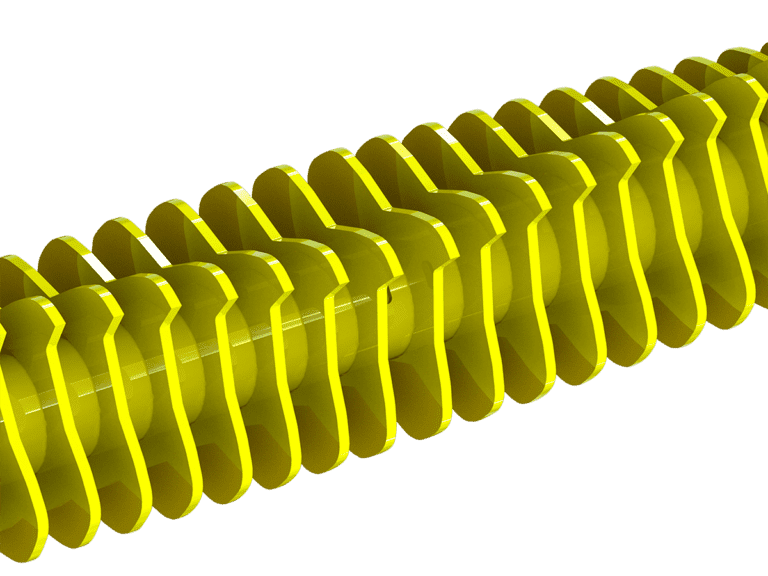

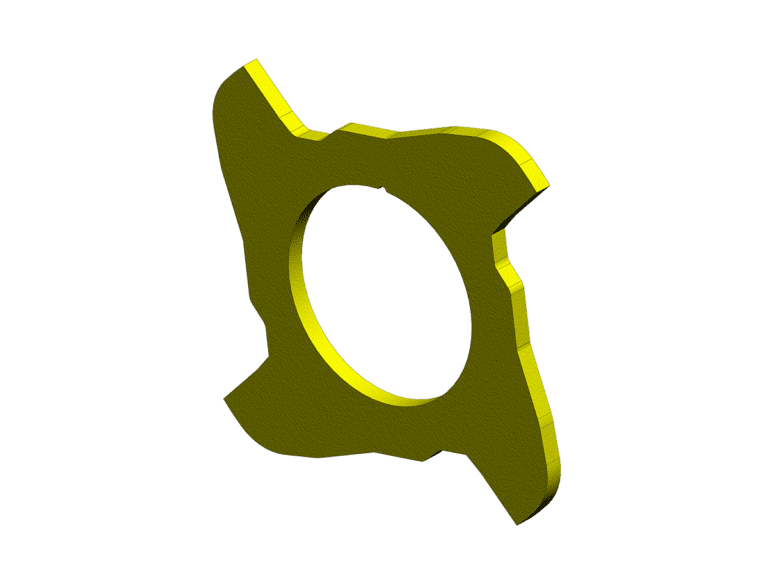

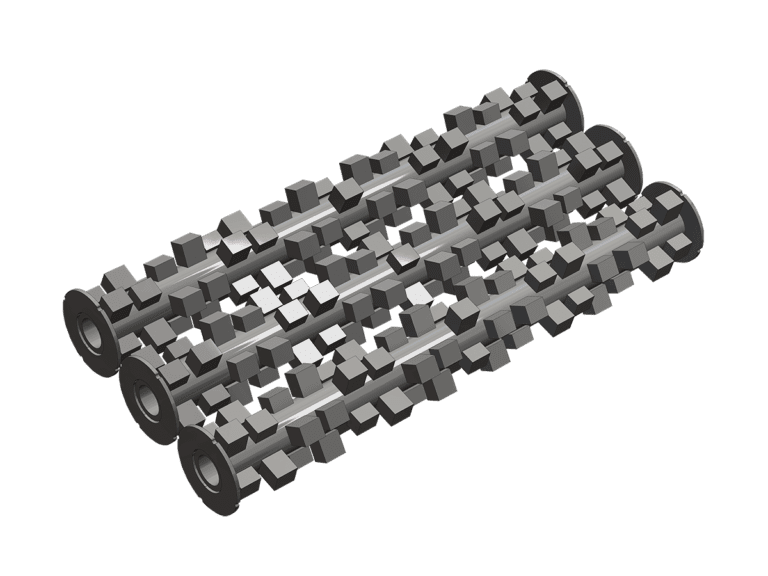

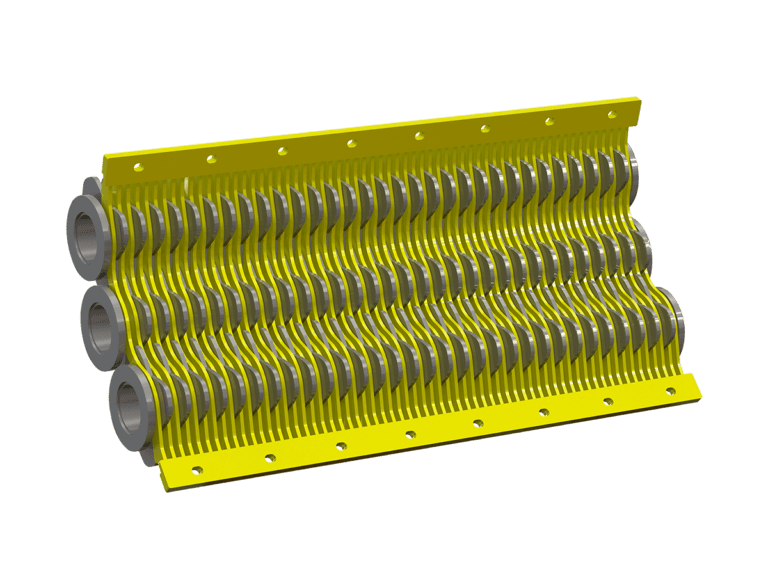

Standard Series

Blade design for screening

The Standard Series is a universally applicable standard blade design, which is also the most commonly used blade model in Vipermetal screening buckets. It’s excellent for screening materials such as soil, lime, peat, and others.

Read more2SC

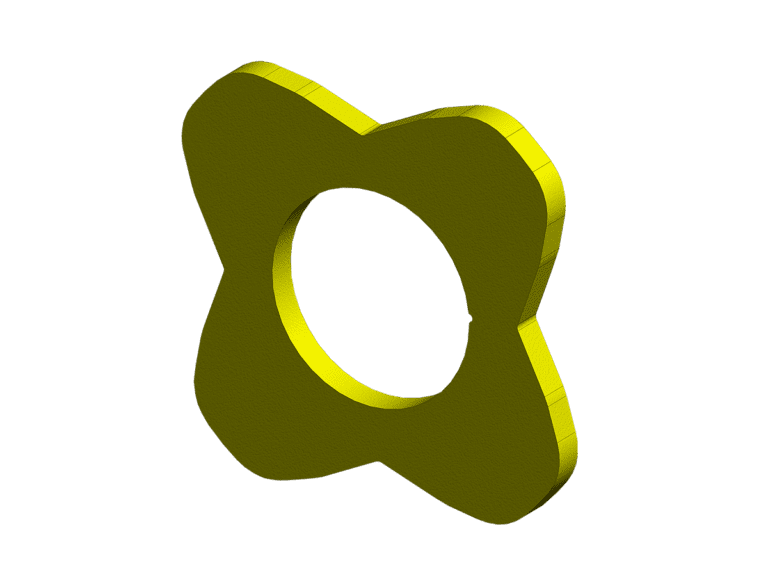

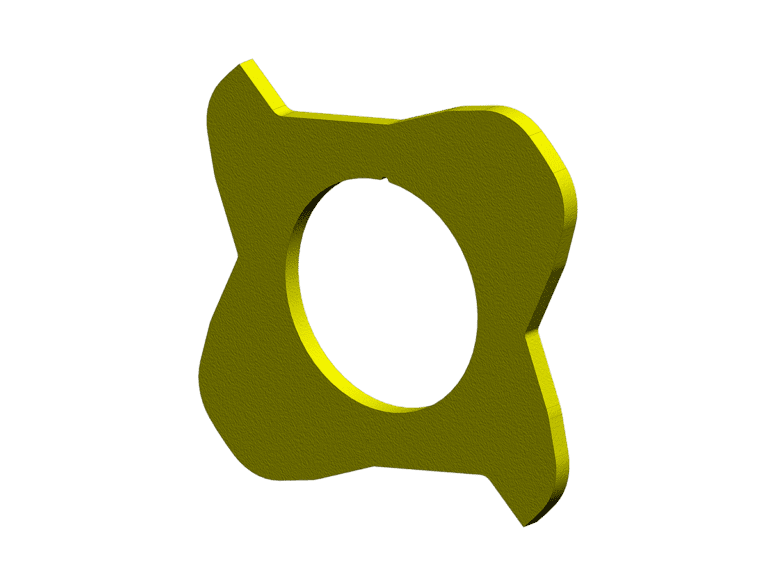

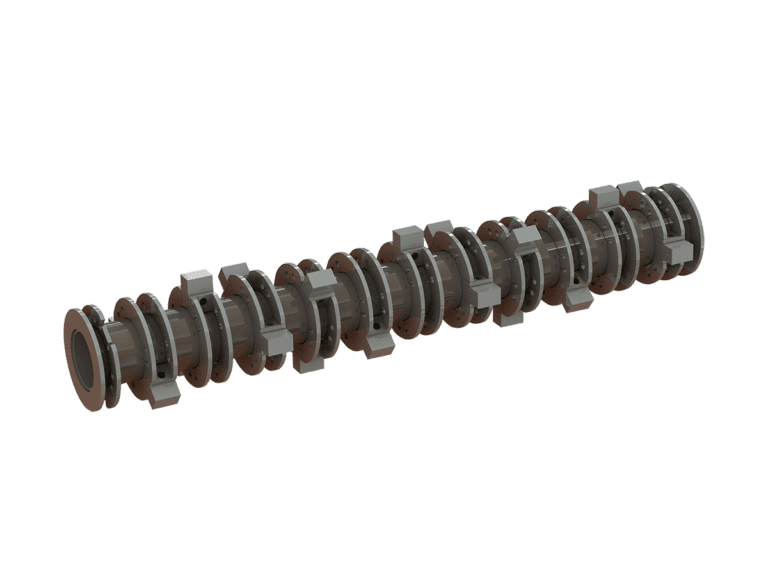

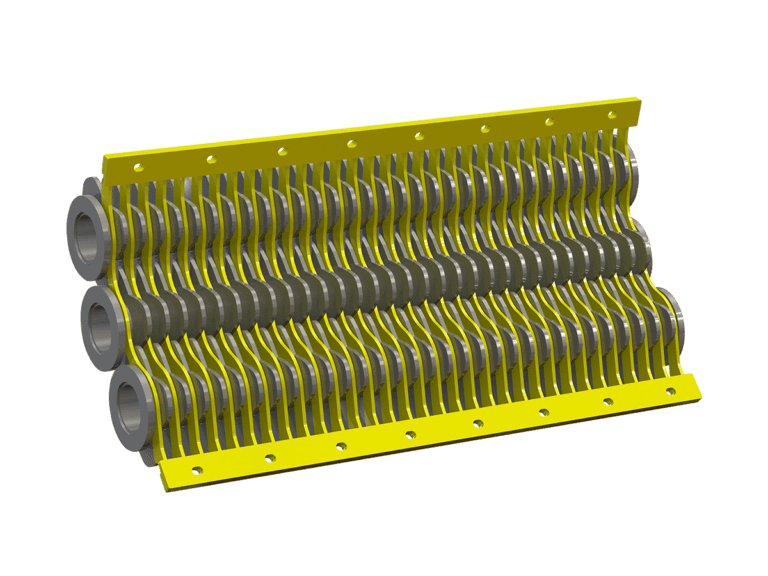

Screening and light crushing

2SC is a lightly crushing blade for applications where, alongside screening, there’s a desire for gentle crushing of soft materials. An equivalent blade option enables a wide range of material sizing, allowing for precise output size in screening-crushing, and homogenizing the material distribution.

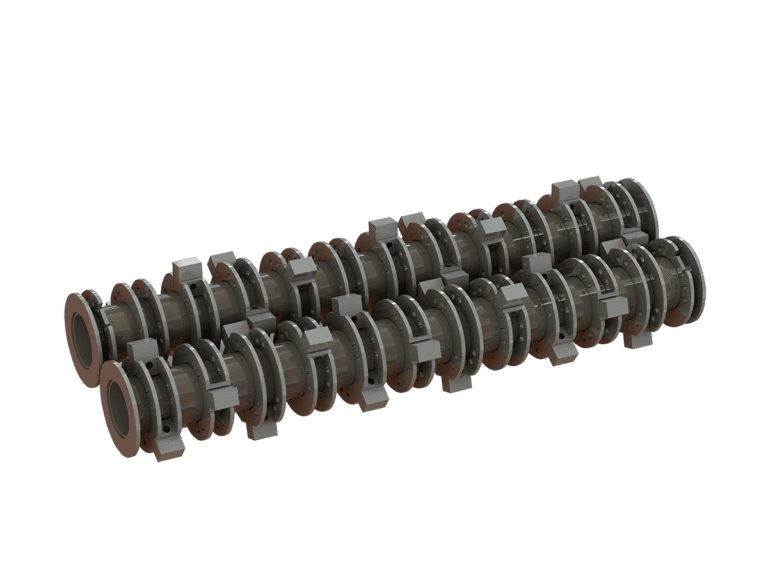

Read more4SC

Blade design for screening and light crushing

4SC is a more aggressive crushing blade than 2SC, designed for soft materials like compacted ones. An equivalent blade option allows for a wide range of material sizing, ensuring precise output size in crushing by homogenizing the material distribution.

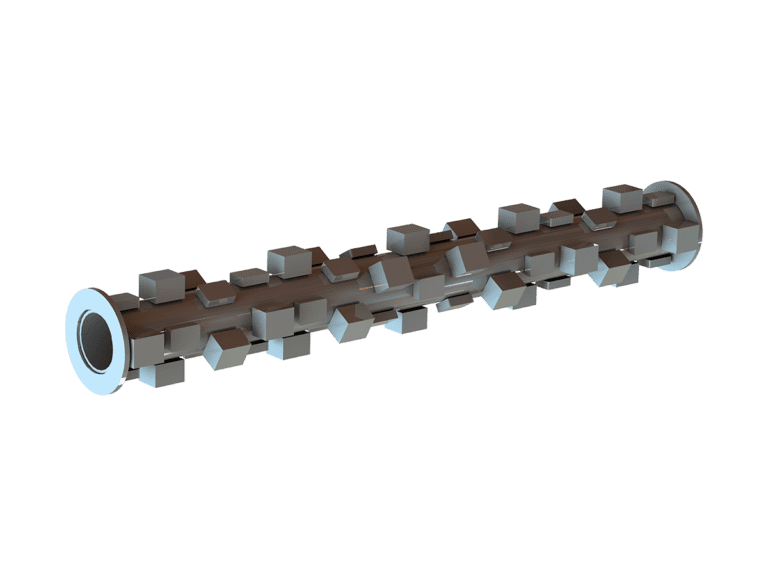

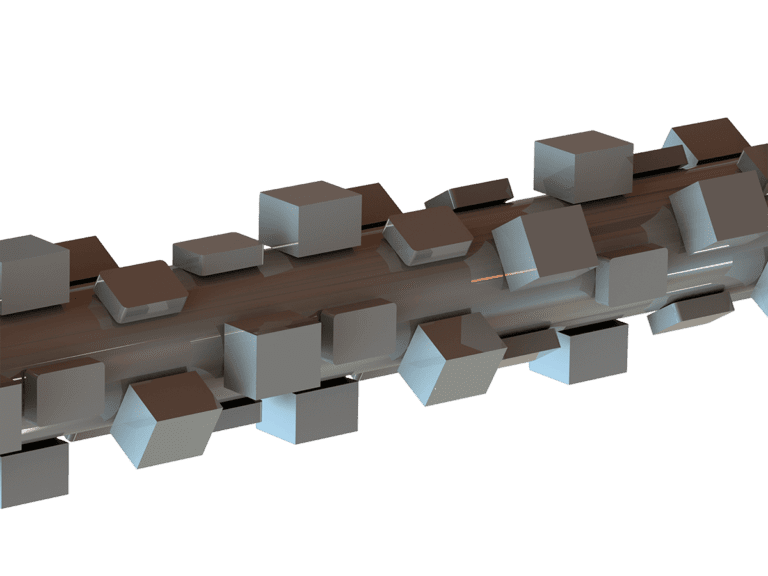

Read moreBigBlock (Welded)

For stabilization and mixing

BigBlock is a blade option for screening buckets, excellently suited for material stabilization and mixing. The large blocks efficiently transfer and partially crush materials with high-capacity

Read moreBoltBlock (Bolted)

For crushing medium-hard materials

Bolt Block is a blade option for screening buckets, suitable for efficient crushing of medium-hard materials such as asphalt, bricks, construction waste, and compost

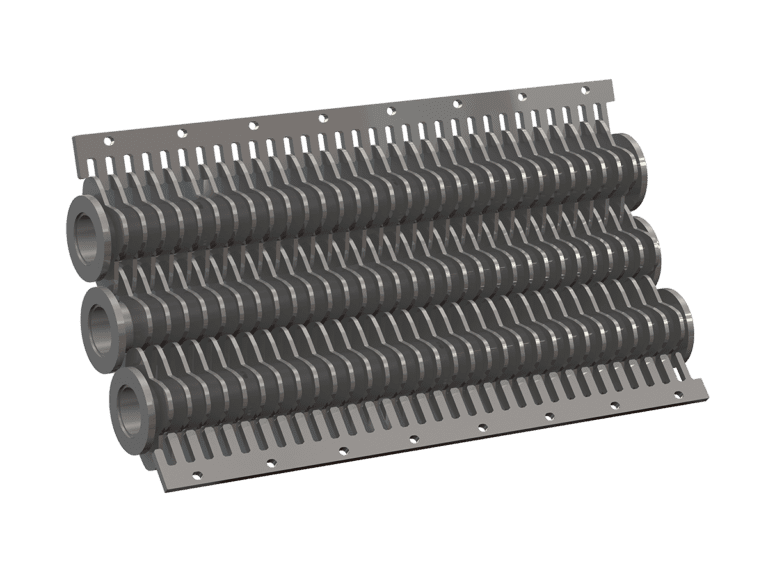

Read moreFine Screen Grid

System for screening and light crushing

Fine Screen Grid is a unique option when versatility is desired from the bucket. Unlike traditional options, this choice allows the bucket to be equipped with multiple particle size applications, which can be easily changed even on-site.

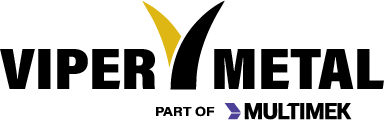

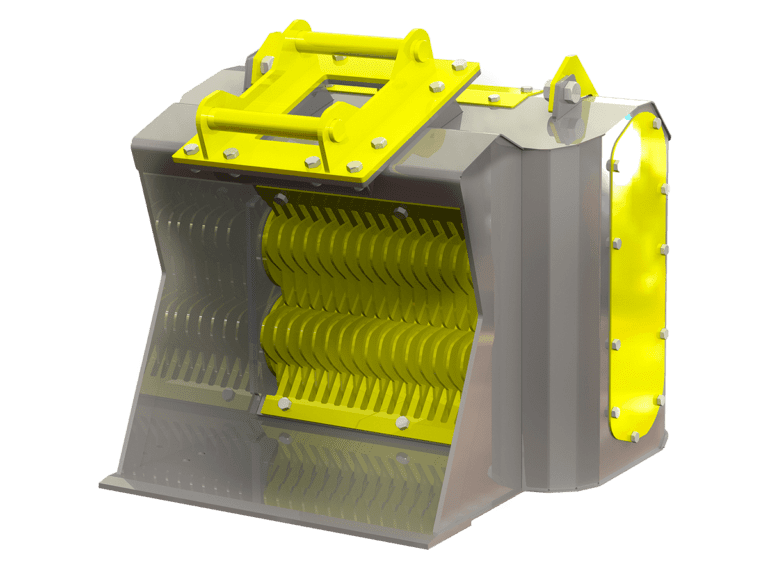

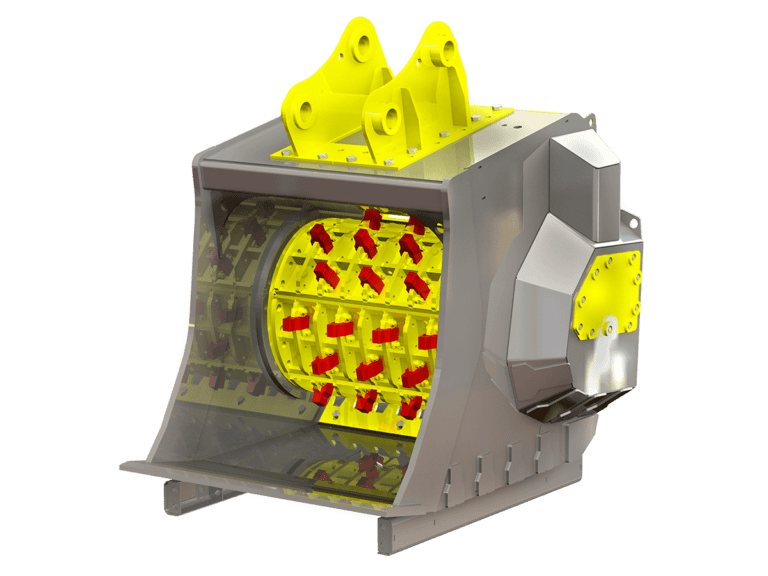

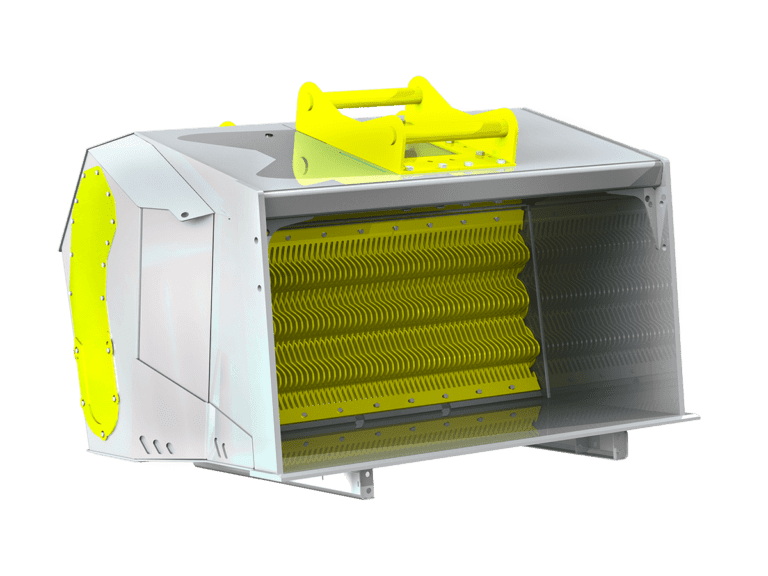

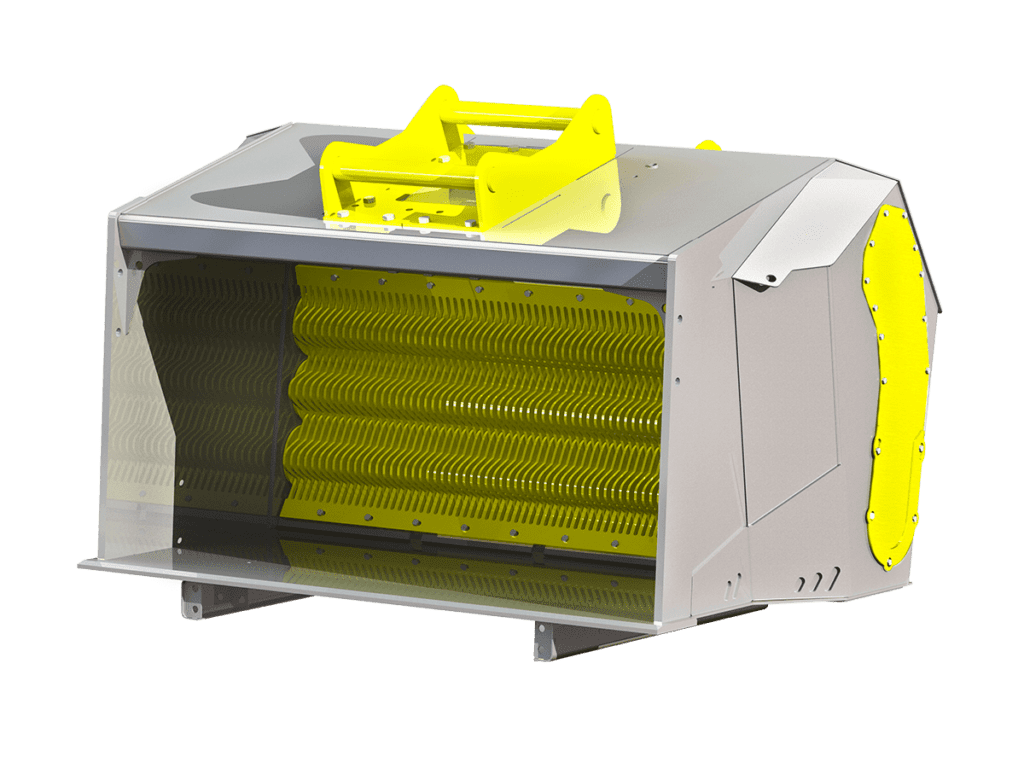

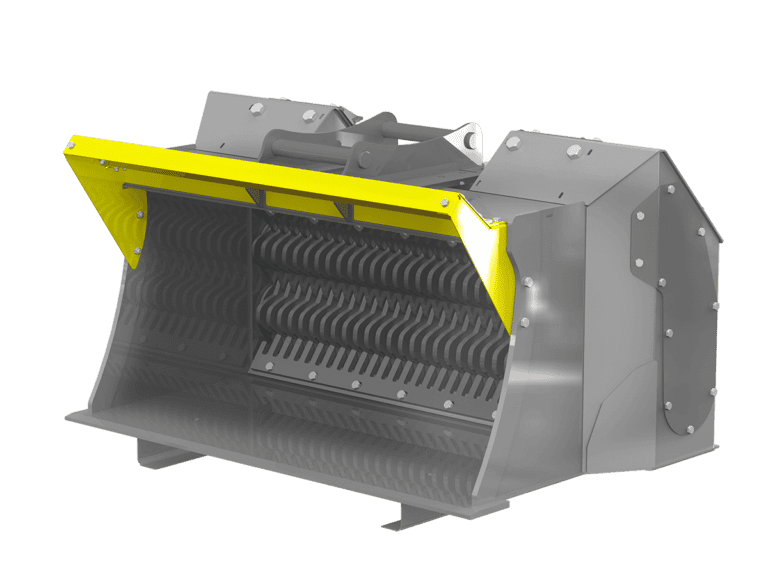

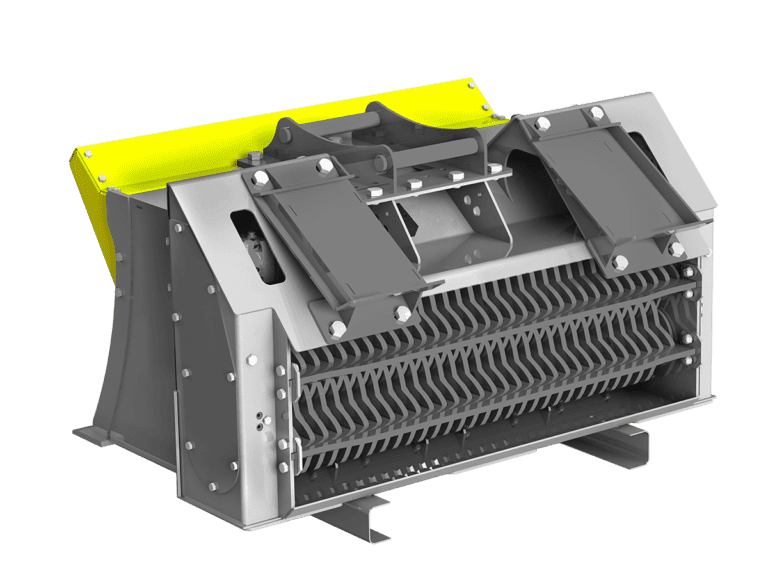

Read moreImages of the VPH 3-2300

Accessories and equipment

Accessories and equipment for VPH 3-2300

A collection of various accessories and equipment is available for screening buckets, designed to enhance efficiency, versatility, and durability in different working conditions.

Extension kit for Screening Bucket

Screening efficiency-boosting and waste-reducing extension edges

Vipermetal screening buckets are available with screening efficiency-enhancing extension kit edges, allowing an increase of up to 20% in the amount of material managed by the mesh bucket at once.

Read moreLeak line/tank line compensator

For applications where tank line connection is not available

The tank line compensator is used in applications where there is no possibility to connect the tank line in the machine. With Vipermetal’s developed valve technology, the tank line can be safely left disconnected without causing damage to the device’s motors.

Read moreWeld-on additional lip plate

Durability against wear for screening

The additional lip plate provides users with the opportunity to enhance the durability of the screening bucket and extend its lifespan. This is particularly valuable in situations where the mesh bucket is exposed to heavy wear or impact, such as handling icy or rocky materials.

Read moreBottom wear plates for Screening Bucket

Durability against wear for heavy use and extreme conditions

By using wear plates on the screening bucket, you increase its resistance to wear, thereby extending its lifespan. Wear plates may be necessary, especially when the bucket is frequently used or in conditions of high abrasion.

Read more

Warranty

All Vipermetal screening buckets, crushing buckets, and other products come with a full factory warranty. This warranty covers any potential manufacturing defects and material faults that may occur during normal use.

Would you like more information about this product or wish to request a quote?

We’d be happy to provide more details about our products and assist you in finding the best possible solution for any situation. You can also inquire about financing options that allow you to evenly spread the costs associated with acquiring a new screening bucket, to be offset with the additional income it brings.