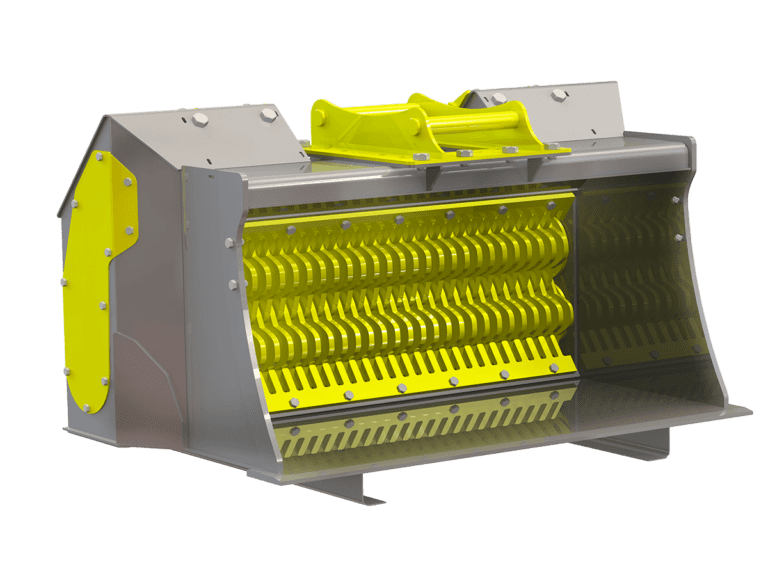

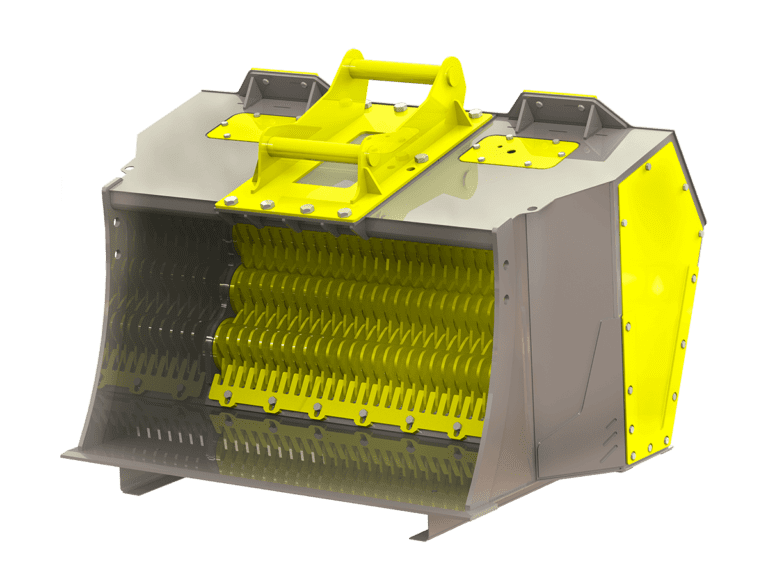

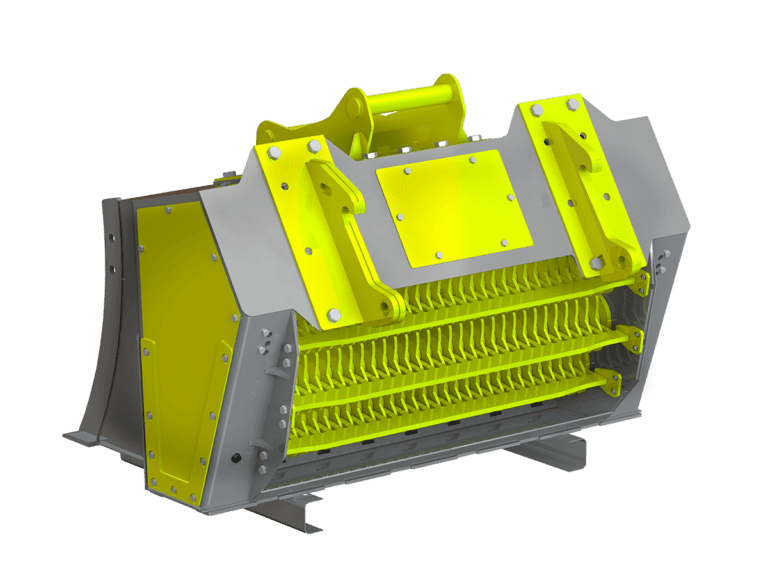

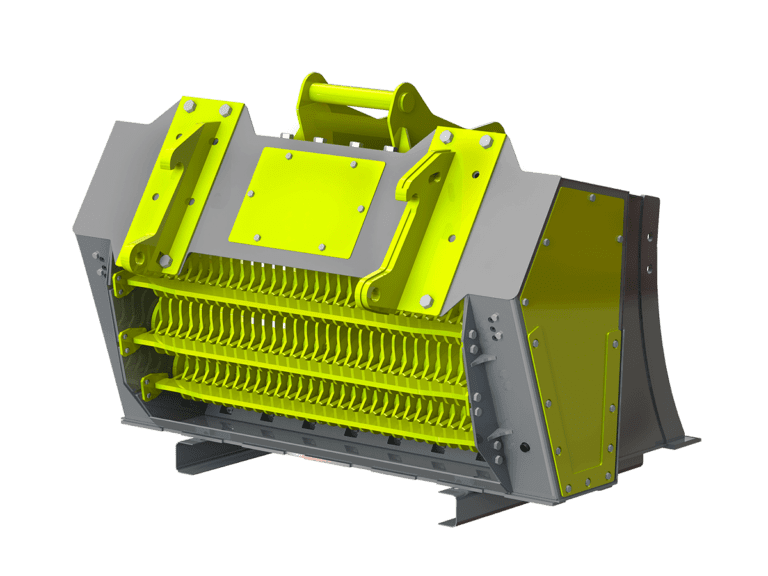

Screening Buckets for All Your Screening and Light Crushing Needs

Vipermetal’s screening buckets are high-quality, durable tools designed for versatile and efficient material handling. Ideal for screening soil, peat, and various aggregates, as well as light crushing, our screening buckets deliver top performance in a wide range of applications.

Made in Finland for Superior Durability

Each Vipermetal screening bucket is manufactured in Finland, using the finest wear-resistant steel grades and premium quality components. This ensures exceptional durability and user-friendly operation, even under rigorous conditions. Our screening buckets are built to last, providing reliable performance in demanding material handling tasks.

Engineered for Precise Screening and Efficient Crushing

Vipermetal’s advanced screening buckets are specially engineered to endure challenging environments, delivering precise screening and efficient crushing every time. They are the trusted choice for professionals seeking optimal results in material processing, no matter the project size or scope.

Choose Vipermetal Screening Buckets for High-Quality Performance

When you choose Vipermetal’s screening buckets, you invest in a reliable, high-quality solution for all your material screening and crushing needs. Whether you’re working on small projects or large-scale operations, our screening buckets are designed to meet the highest standards of durability and performance.

Quality for Professional Use

If you’re seeking a screening bucket that endures heavy use and truly enhances the efficiency of screening-related tasks, Vipermetal’s screening bucket stands as the top choice in the market.

- Lightweight structure

- Easy and quick to use

- Top-notch durability

- Wide product range

- Versatile blade assortment

- Compatible with excavators and wheel loaders

- Cost-effective use

- Easy to maintenance

- Comprehensive warranty

- Customizable for special orders

- Made at our own factory in Finland

Models

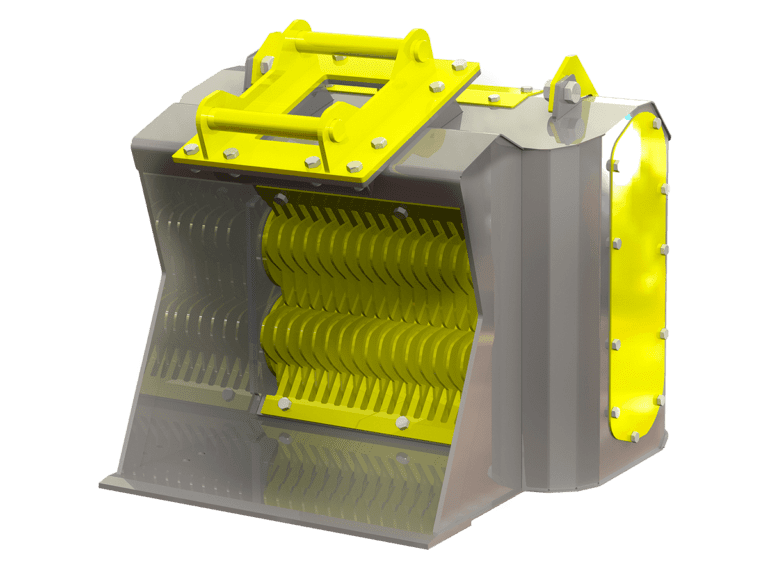

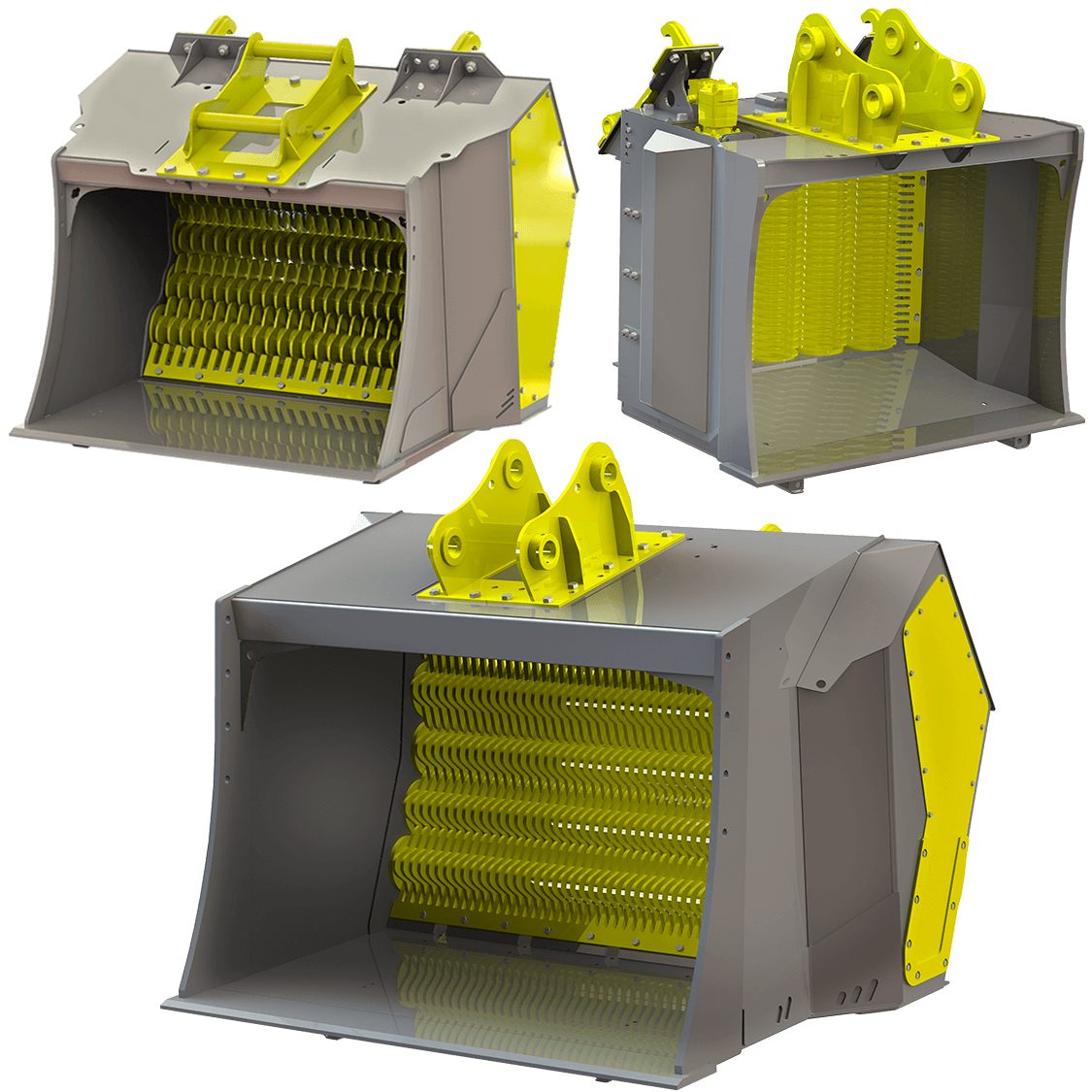

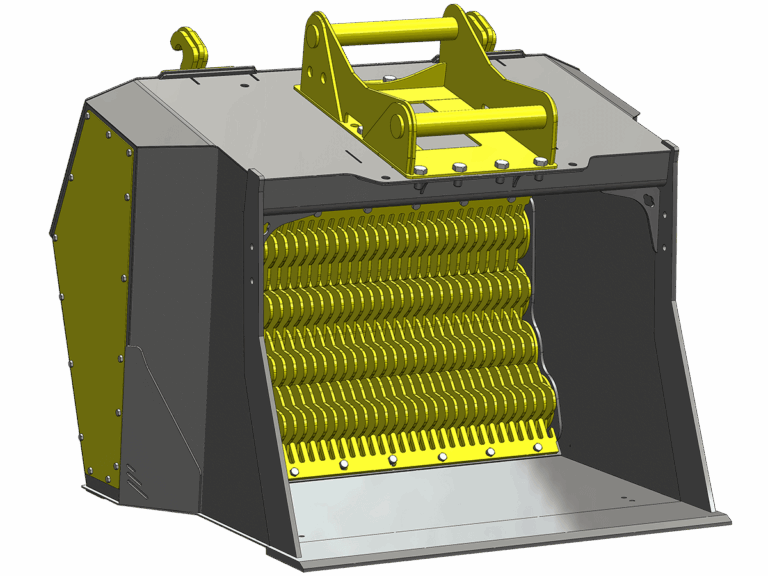

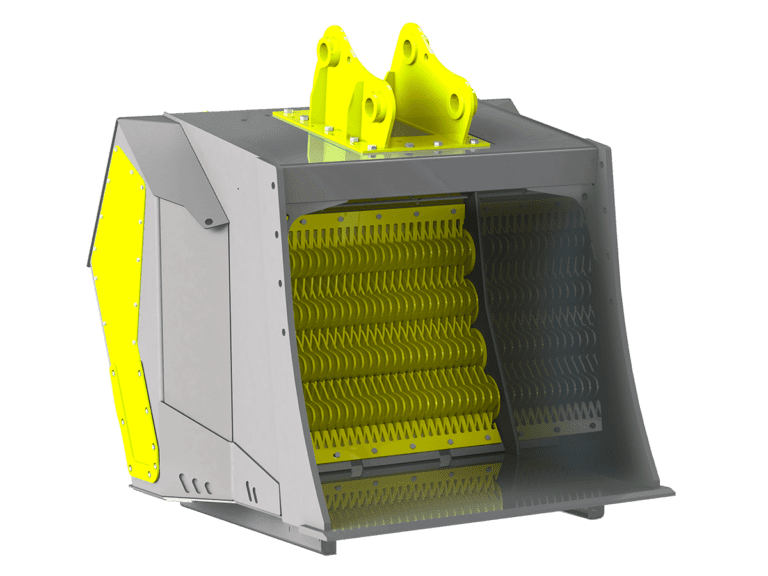

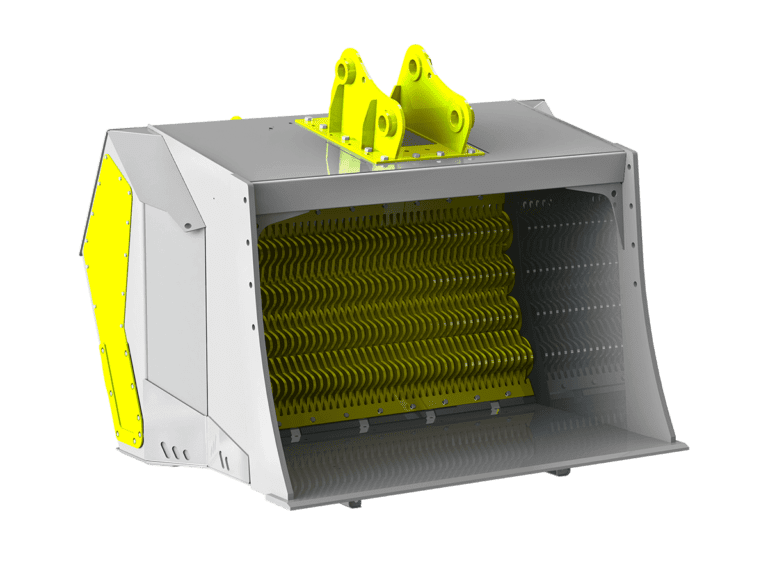

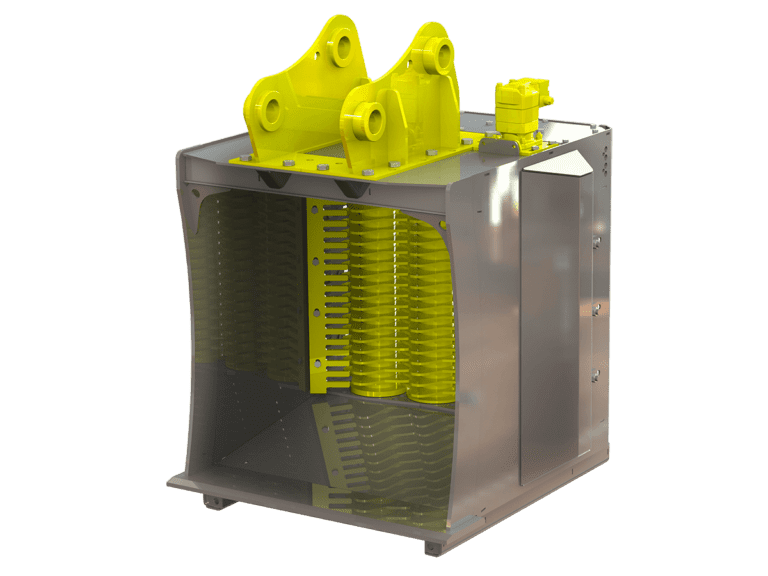

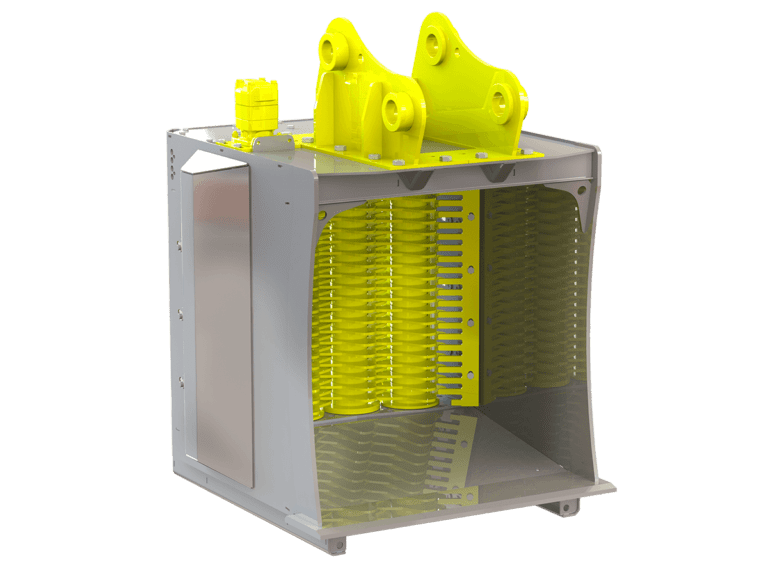

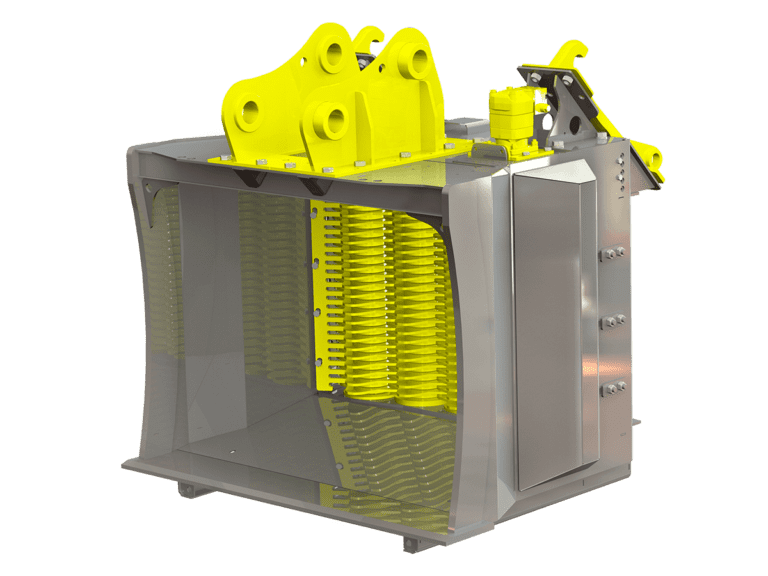

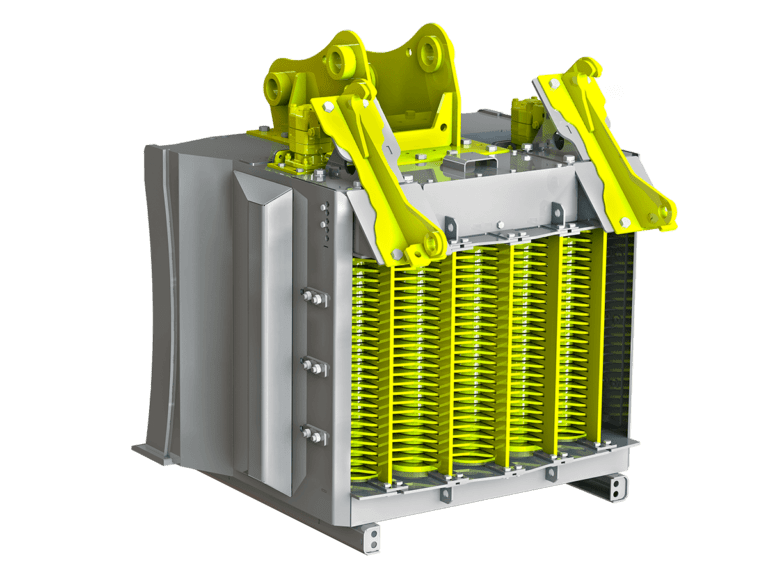

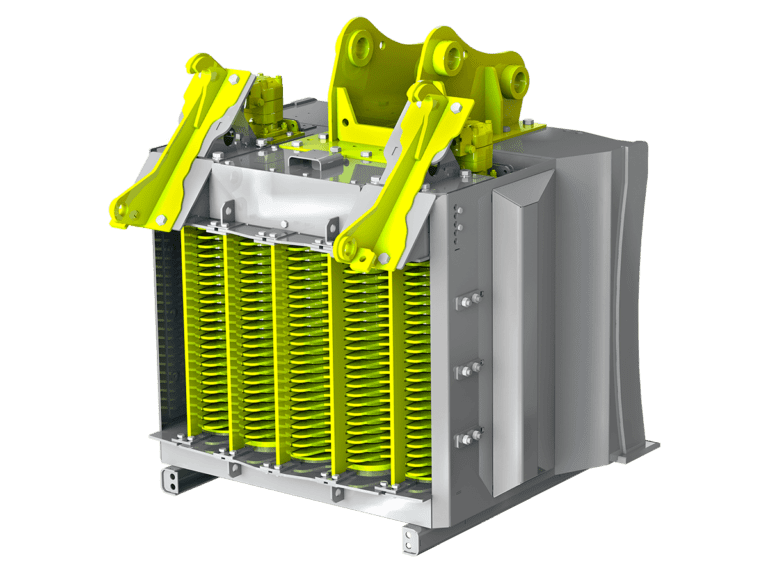

Screening Bucket Models – Tailored Solutions for Every Machine and Screening Application

Vipermetal offers a wide range of screening bucket models, specifically designed to meet the unique requirements of various machine platforms and material screening tasks. Our versatile screening buckets ensure optimal performance for any screening or light crushing application.

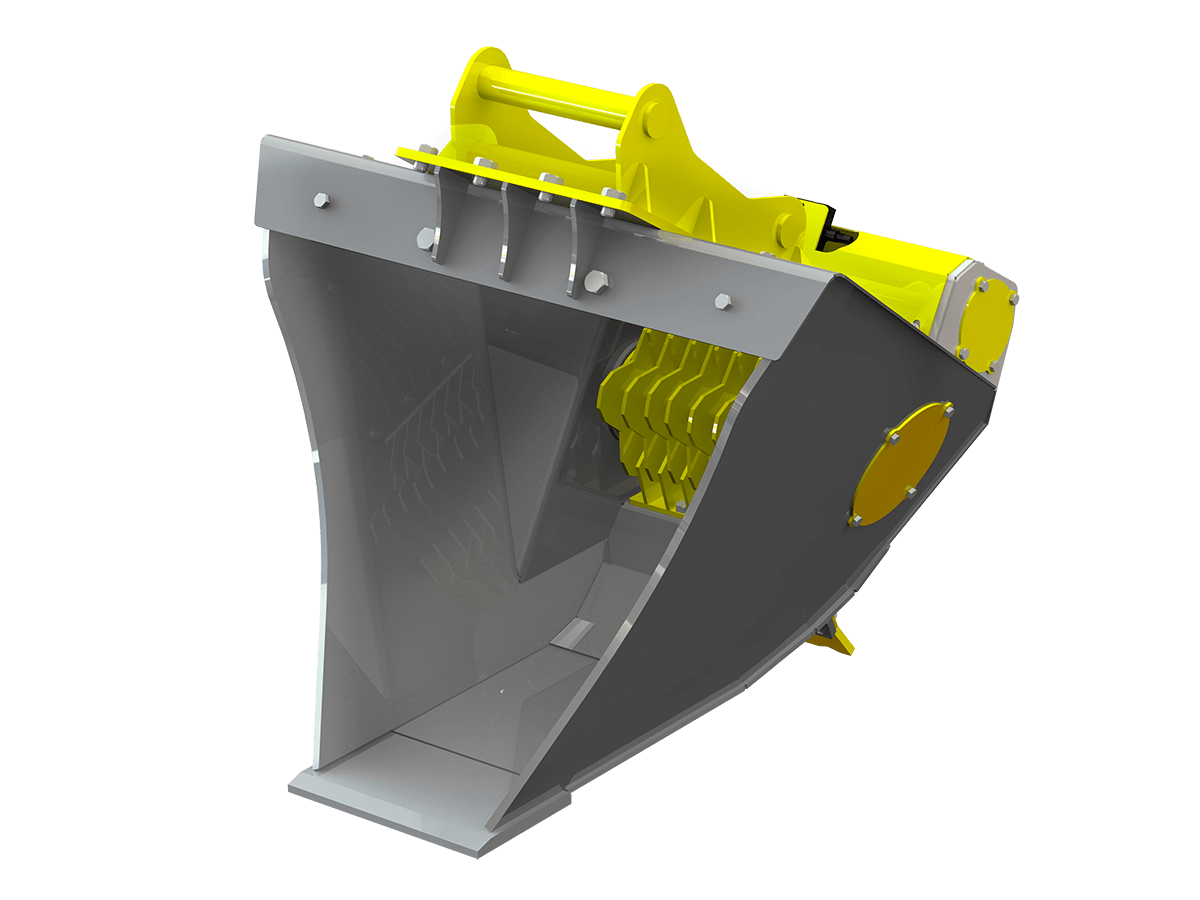

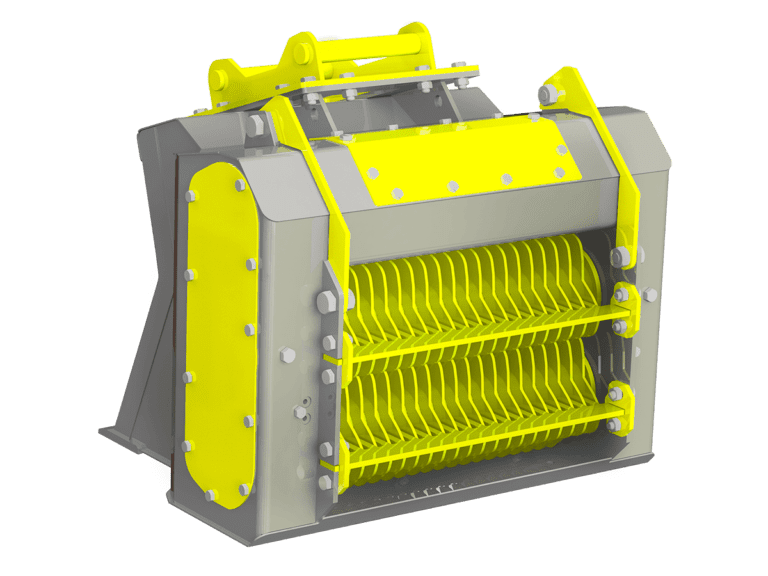

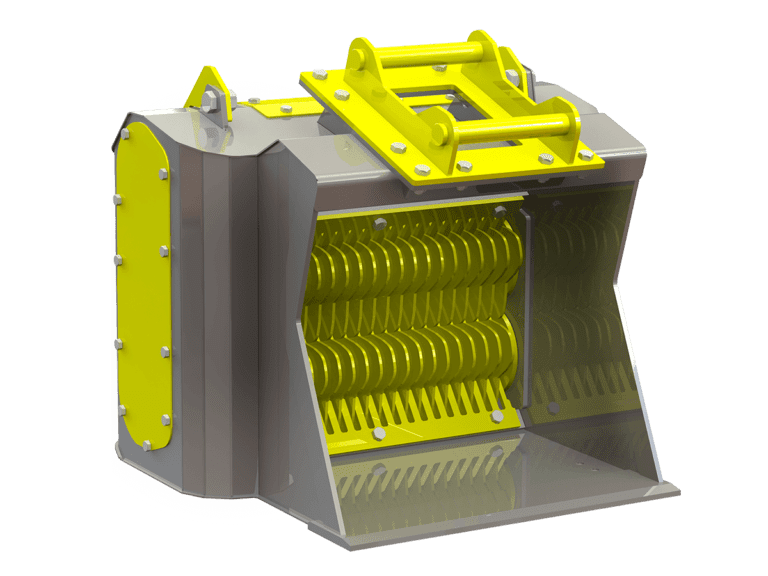

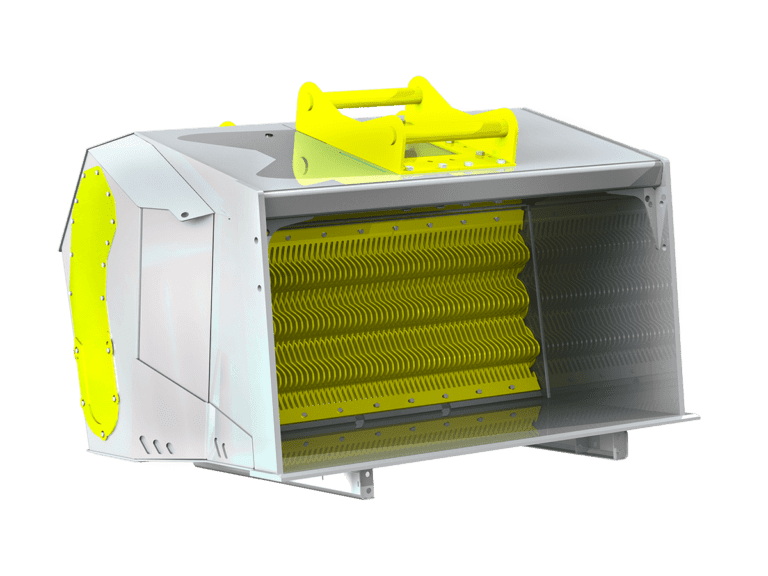

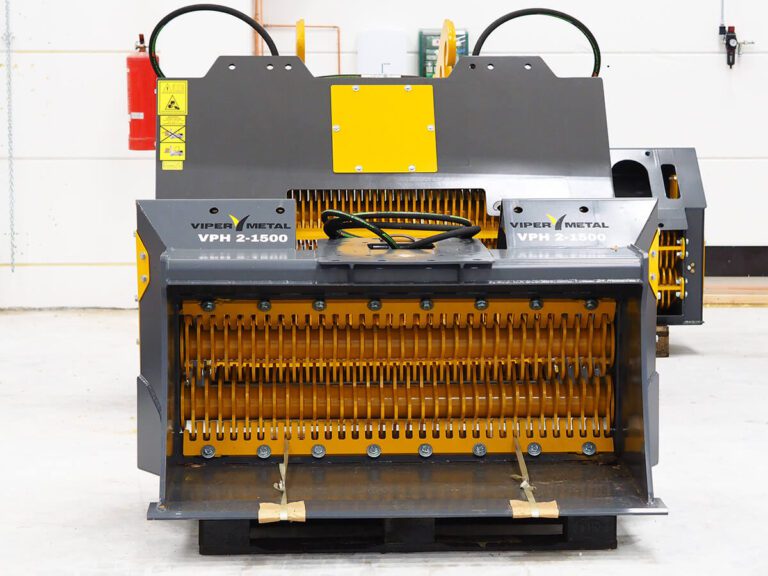

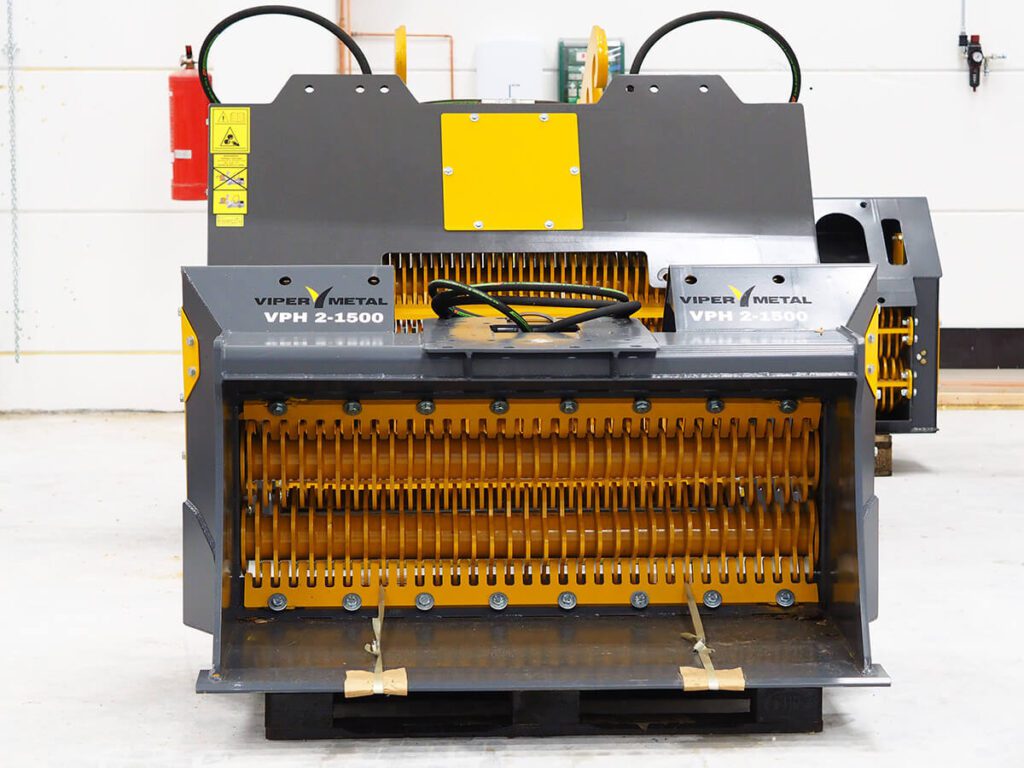

VPH 2-1500

Excavators: 8000-10000

Wheel loaders: 4000-7000

VPH 2-1500 is a popular screening bucket model designed especially for skid steer loaders and small excavators. This versatile screening bucket is excellent for screening and processing various types of materials.

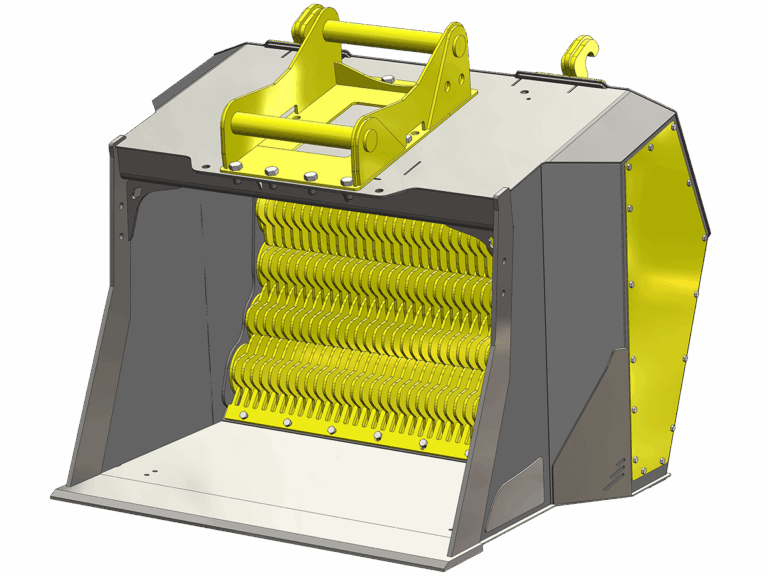

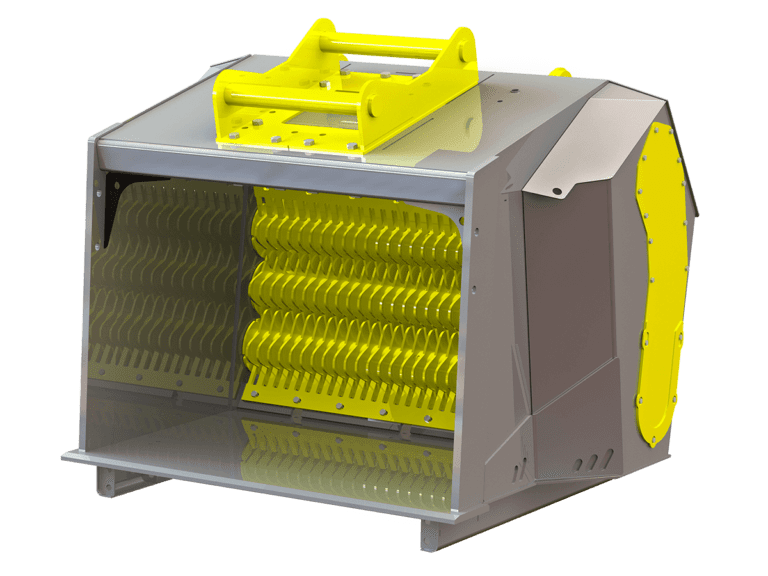

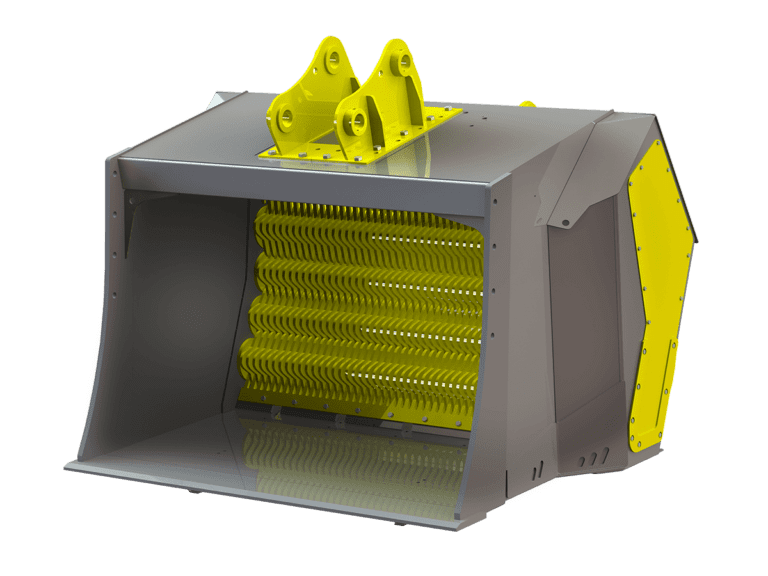

Read moreVPH 3-1500

Excavators: 10000-15000

Wheel loaders: 7000-10000

VPH 3-1500 is a versatile high-quality screening bucket model that is suitable for various screening, processing, and also light crushing of different materials.

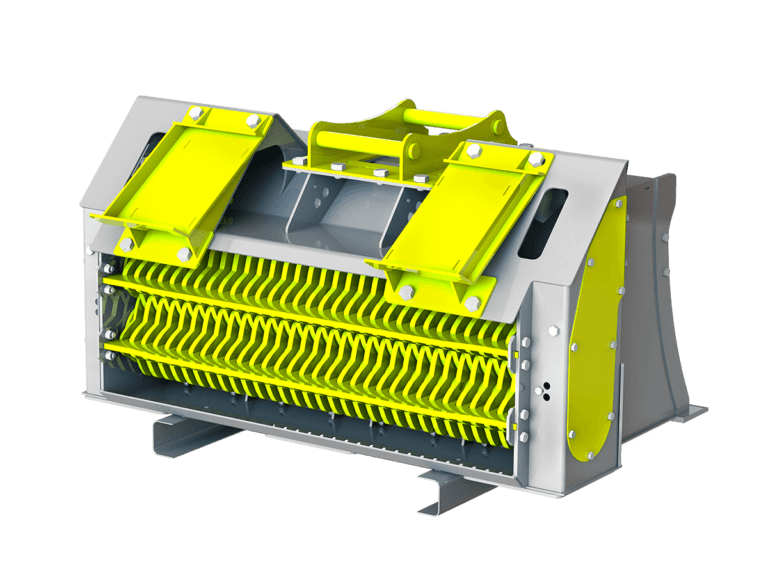

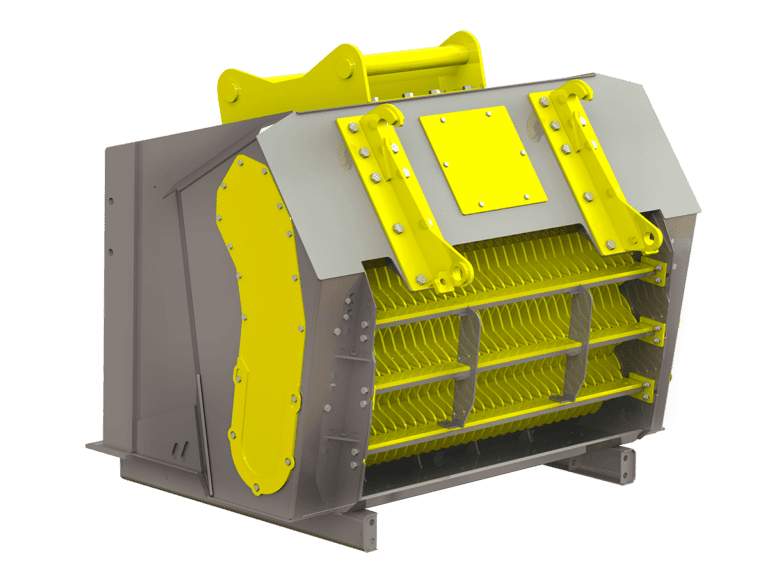

Read moreVPH 4-1502

Excavators: 14000-23000

Wheel loaders: 9000-15000

VPH 4-1502 is an updated version of the legendary 4-1500 model. Suitable for a wide range of machine sizes, both loaders and excavators. Available in a broad selection of optimized versions for fine screening, aeration, mixing, and light crushing.

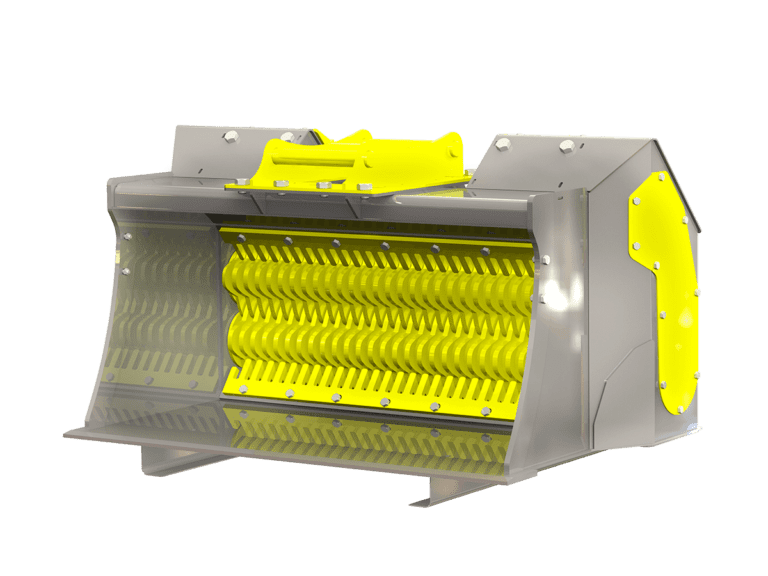

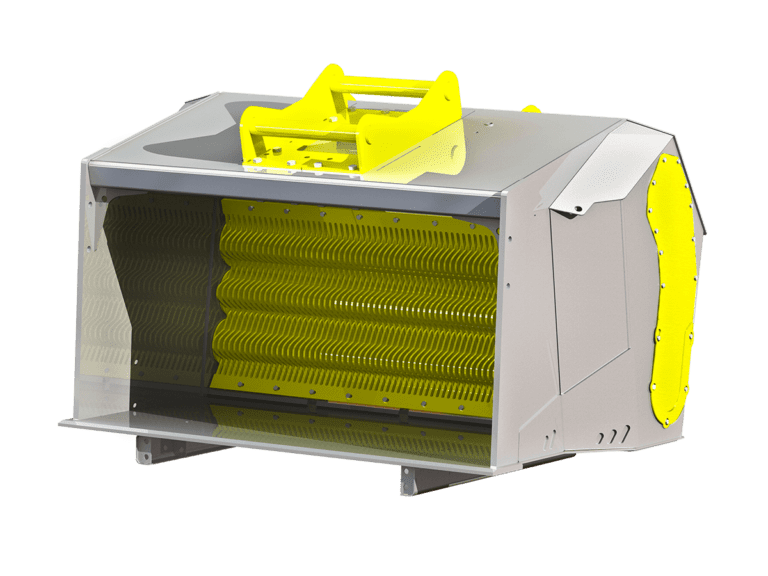

Read moreVPH 3-1700

Excavators: 22000-30000

Wheel loaders: 12000-16000

VPH 3-1700 is a robust and powerful screening bucket model favored by professionals. The model also offers versatile versions for fine screening, coarse screening, and even crushing.

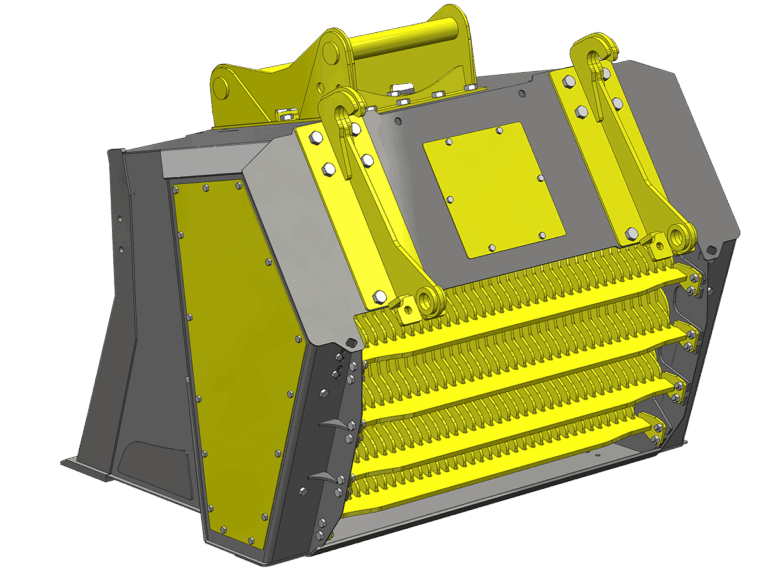

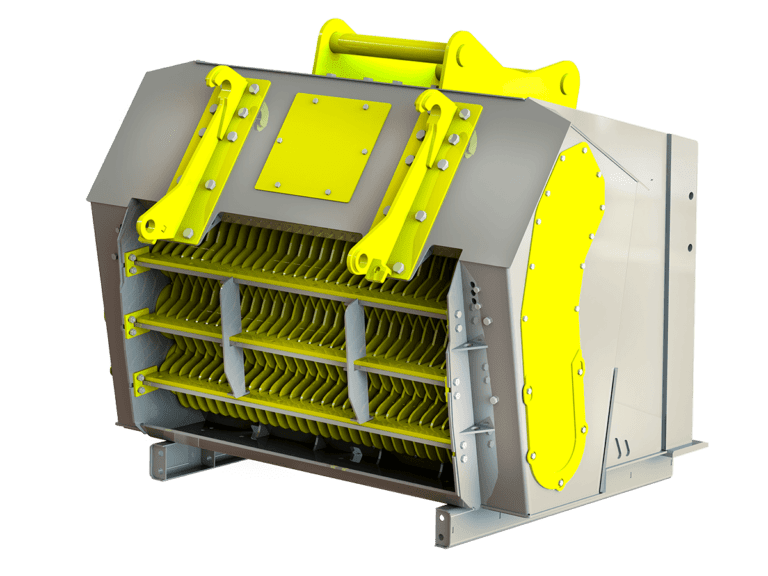

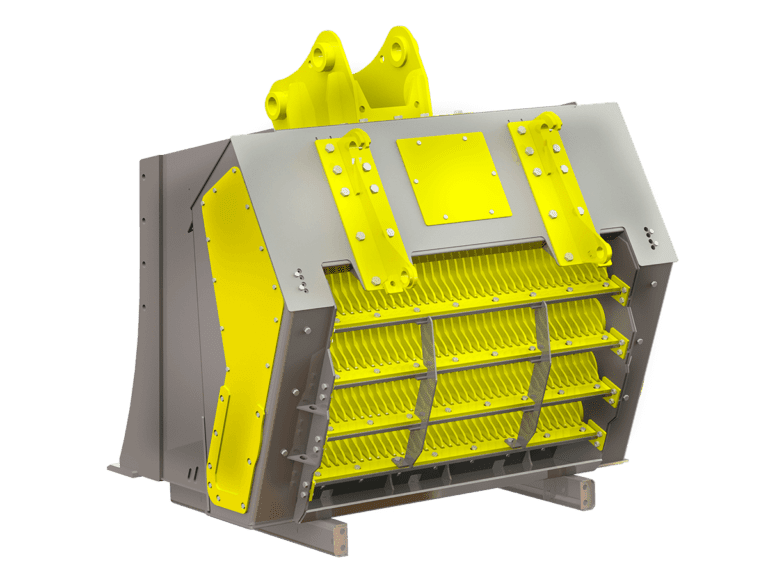

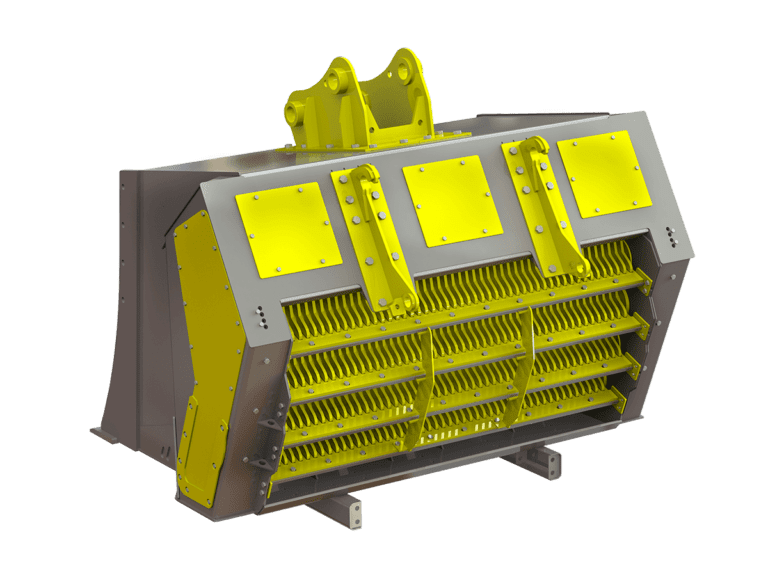

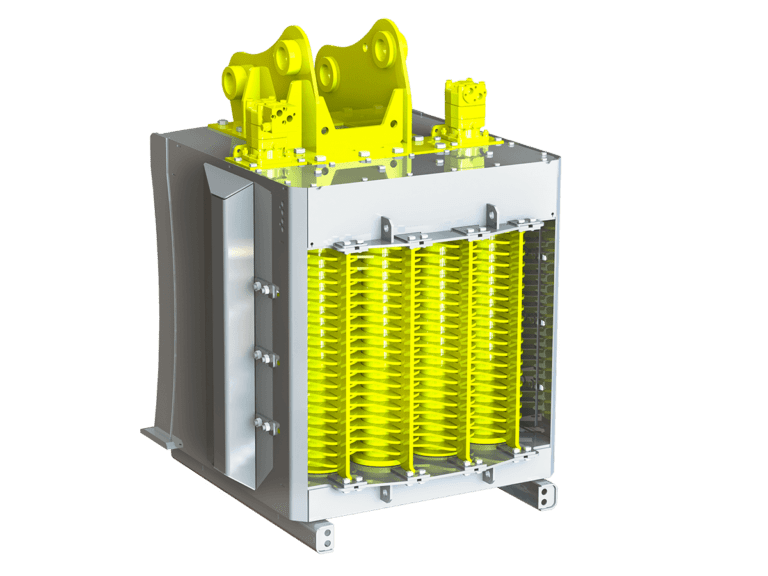

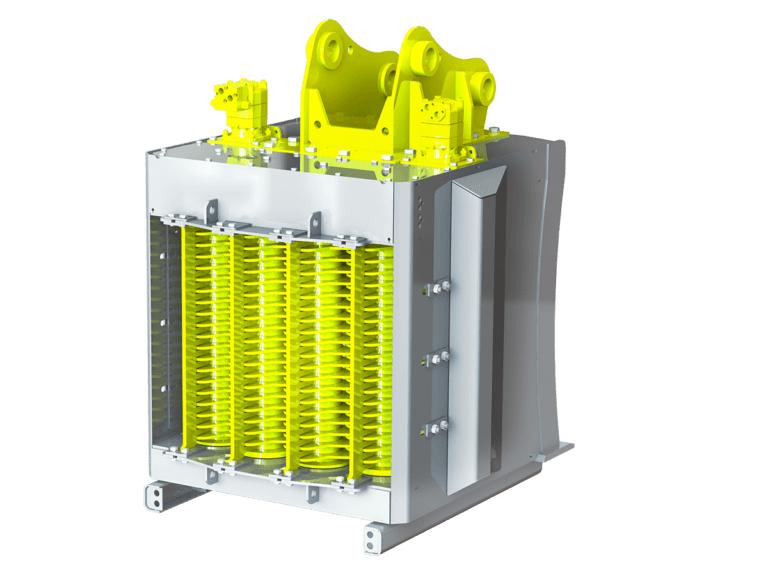

Read moreVPH 4-1700

Excavators: 24000-35000

Wheel loaders: 14000-20000

VPH 4-1700 is the big brother of the 3-1700 screening bucket model with four horizontal rotors for larger machine sizes. There are also several customized versions available for screening and crushing based on specific use cases.

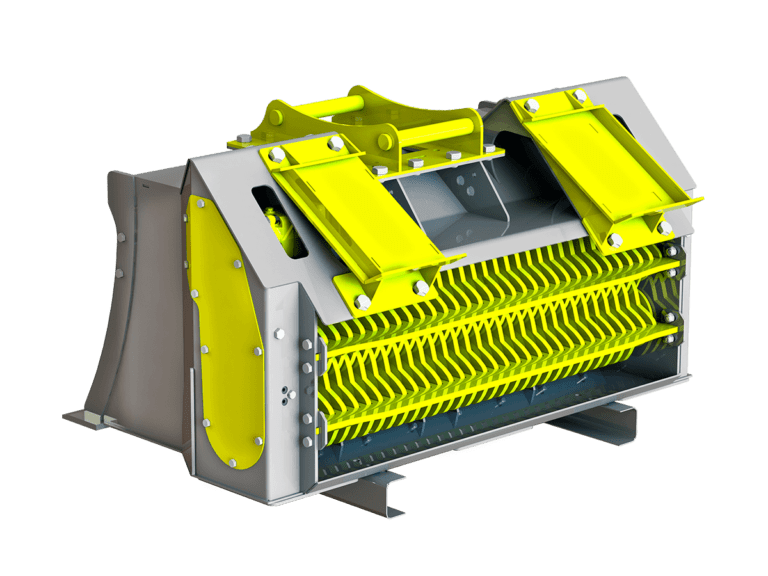

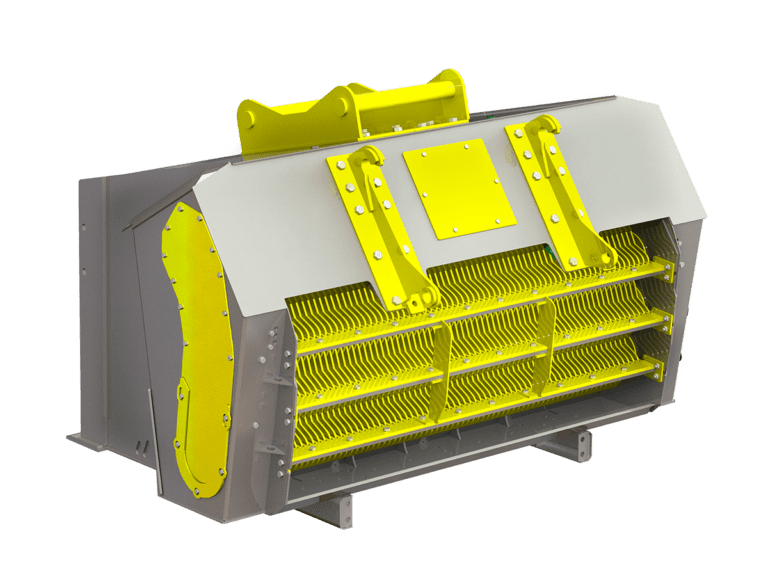

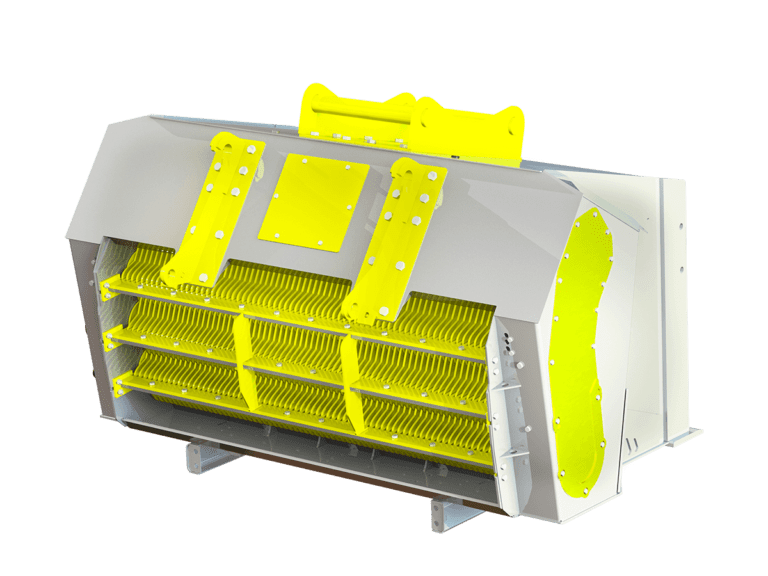

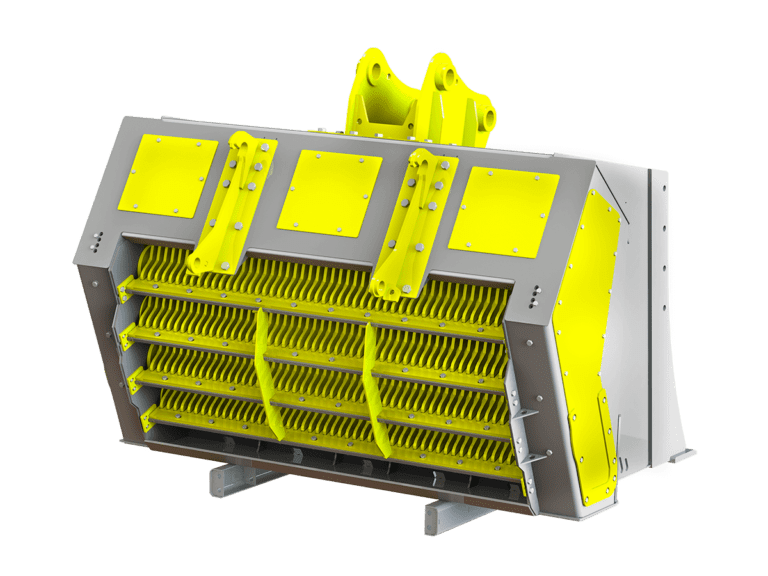

Read moreVPH 3-2300

Excavators: 28000-35000

Wheel loaders: 18000-25000

VPH 3-2300 is a high-capacity screening bucket for wheel loaders and excavators. Its versatile applications include widely used screening and mixing of materials such as peat, aggregates, and biomaterials.

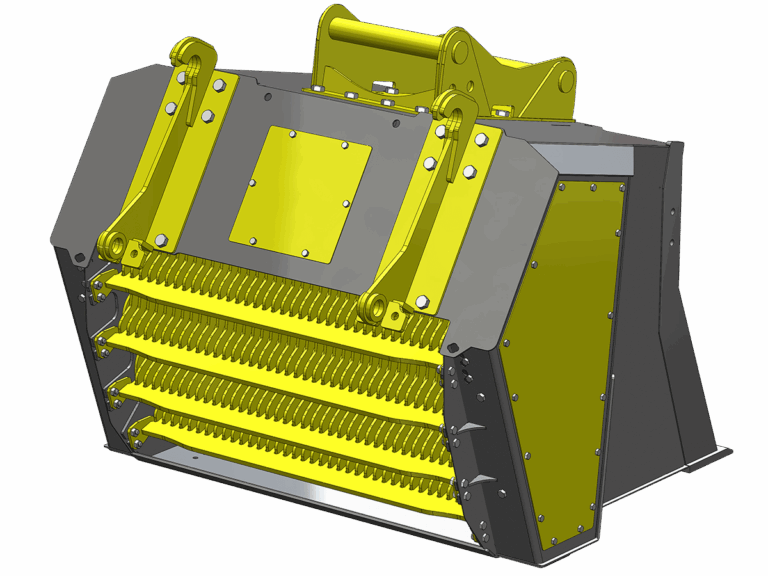

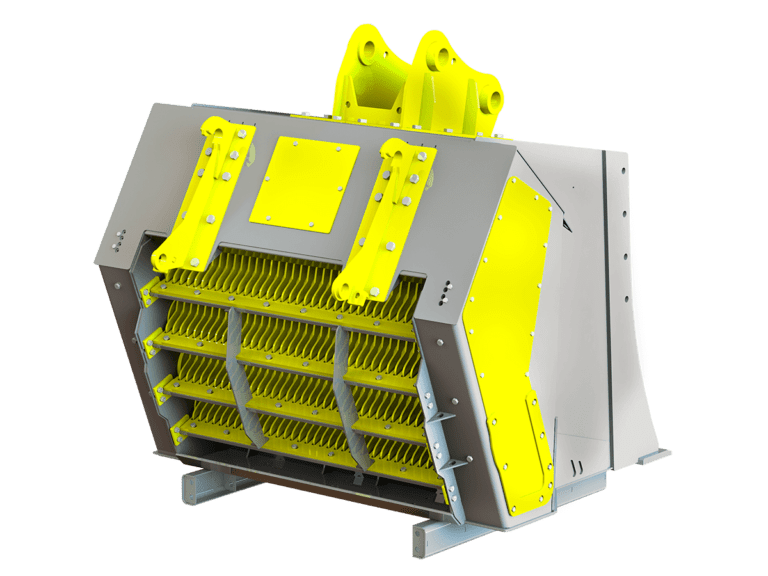

Read moreVPH 4-2300

Excavators: 32000-45000

Wheel loaders: 21000-30000

VPH 4-2300 is the flagship of the Viper screening bucket range. A powerful, high-capacity screening bucket designed for screening large volumes. With additional sides, the bucket volume can reach up to 5600

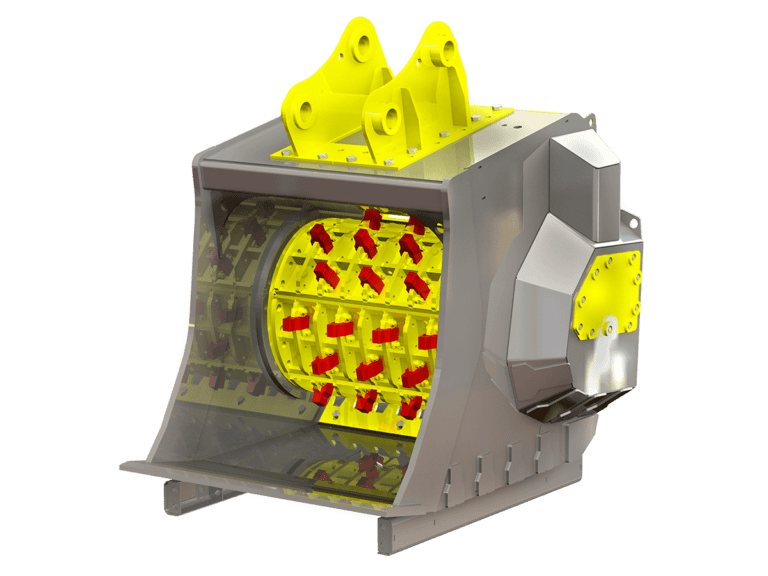

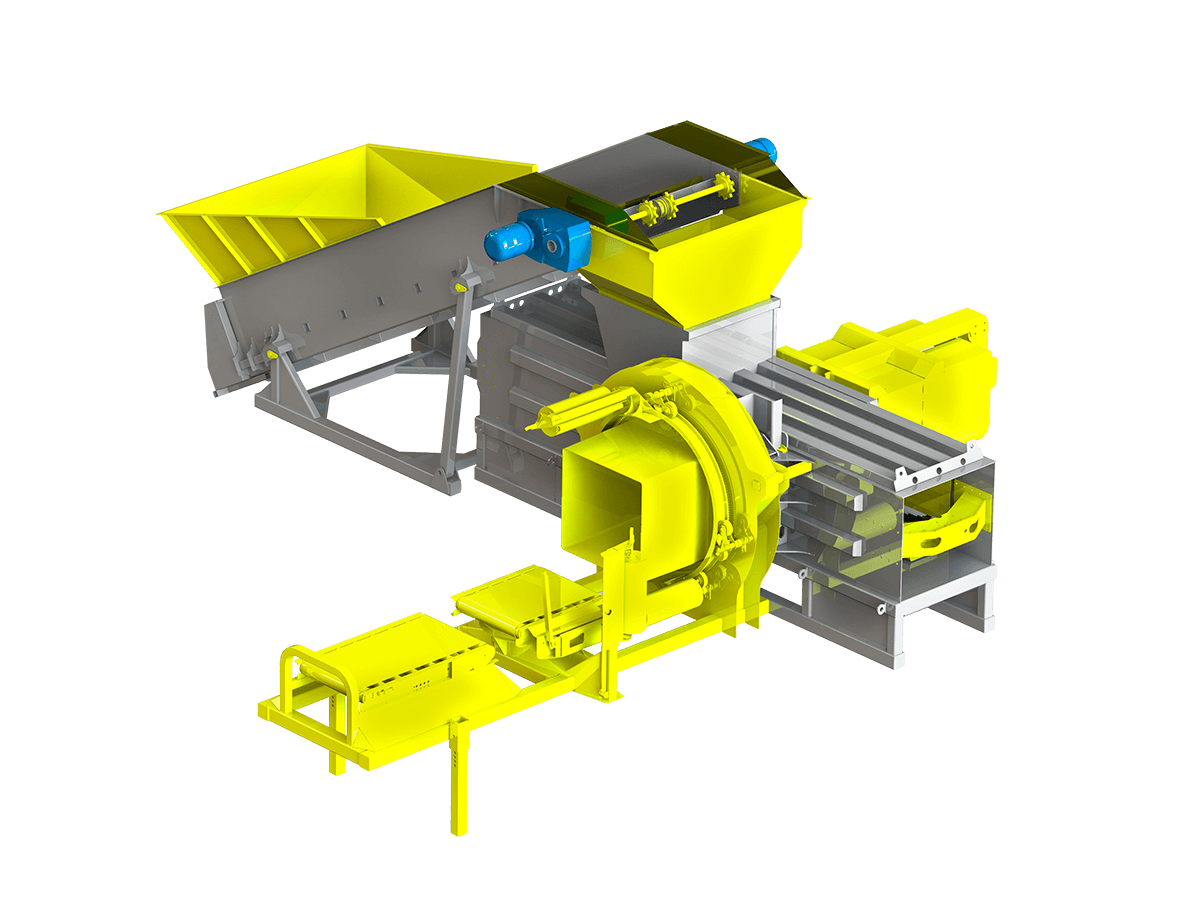

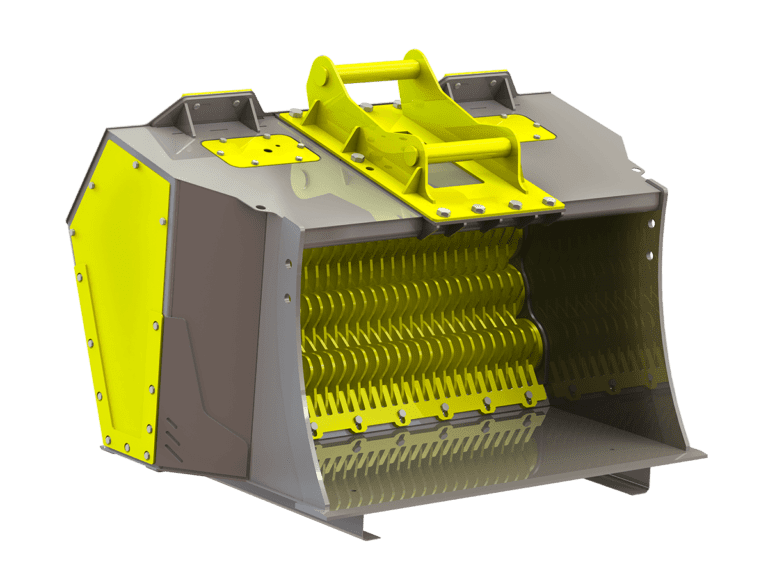

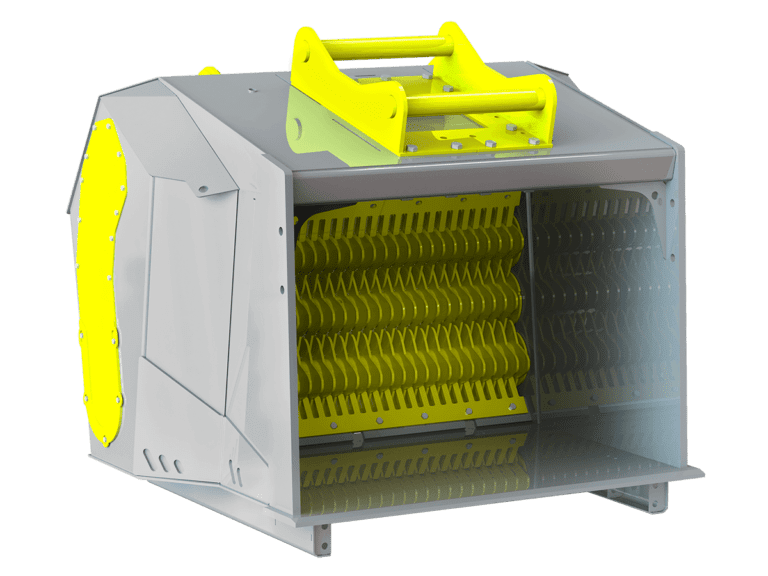

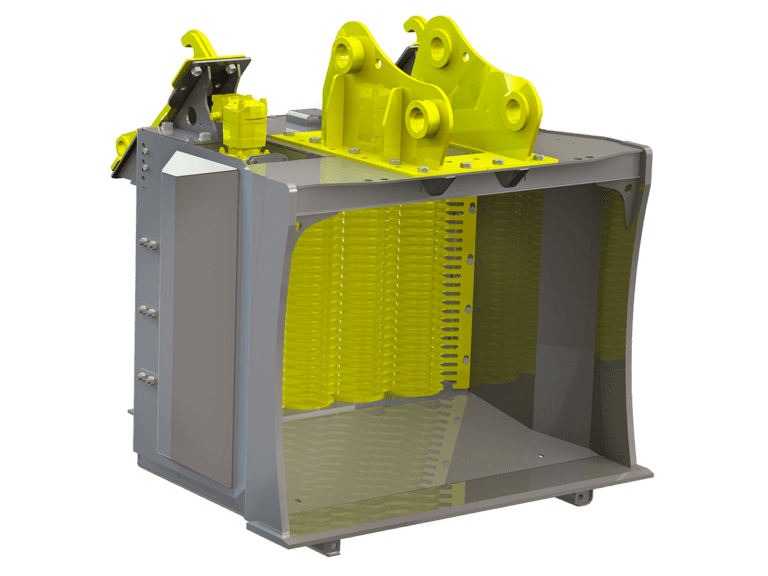

Read moreVPV 4-1100

Excavators: 14000-22000

VPV 4-1100 is a classic in the Vipermetal screening bucket range. This vertical drum model designed for excavators is an efficient and robust screening bucket for demanding use.

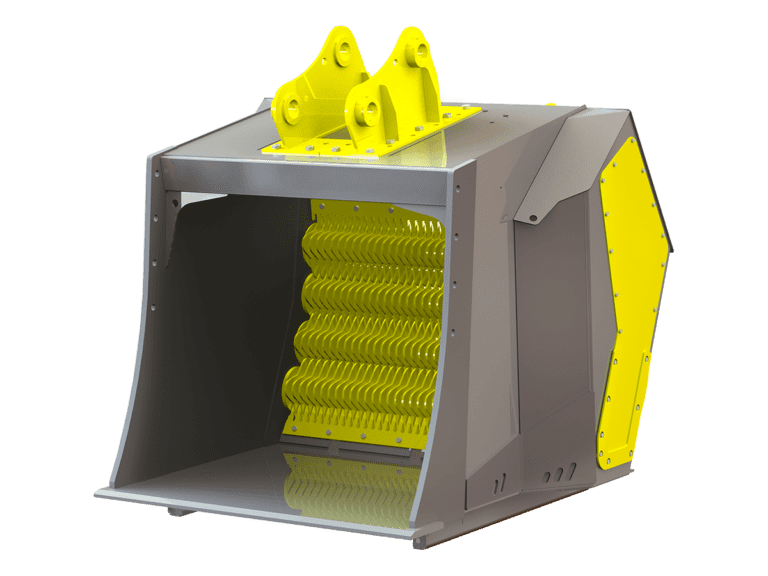

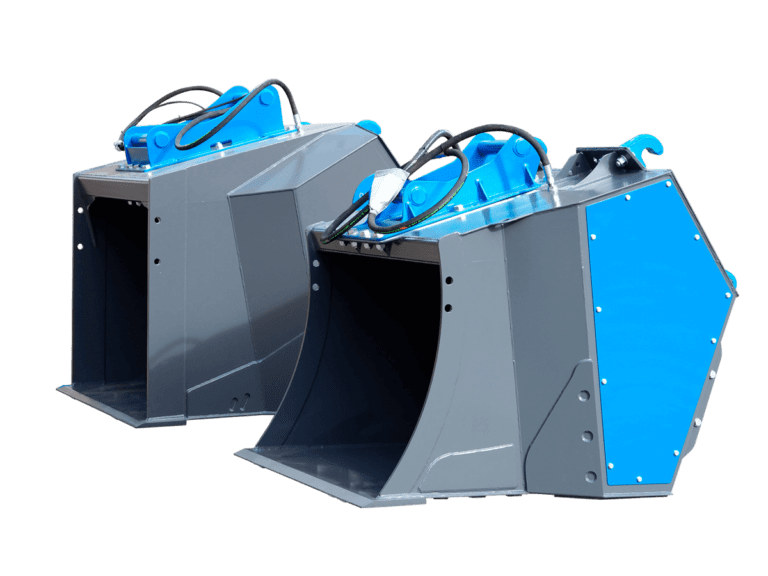

Read moreVPV 5-1350

Excavators: 20000-28000

Wheel loaders: 12000-16000

VPV 5-1350 is a vertical drum high-capacity screening bucket for various uses. Screening and crushing of aggregates are efficient with this bucket, favored by professionals.

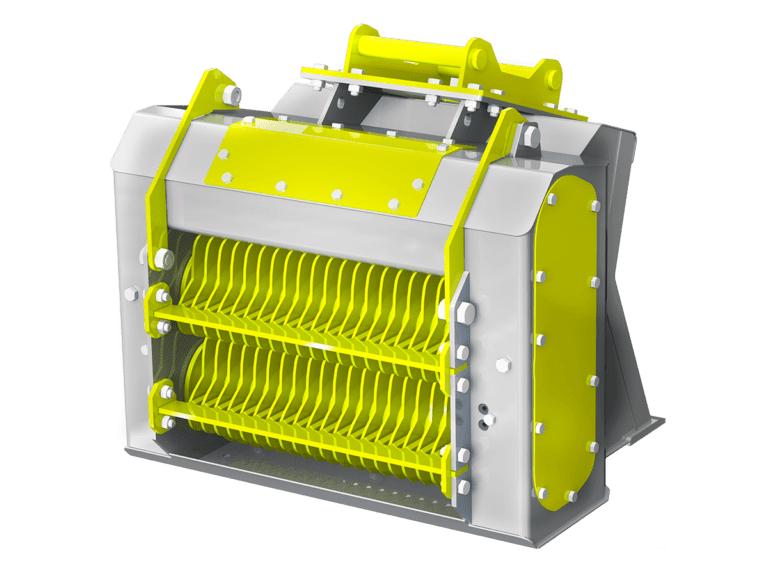

Read moreVPH/VPV Custom

Customized screening bucket models

Vipermetal screening buckets can also be fully customized according to the specific features desired by the customer. As a result of the design work, a series of more specialized frame types have been developed, which can serve as a basis for creating new models.

Read moreVideo

Watch the Presentation Video of Screening Buckets

Watch a brief introduction video of Vipermetal screening buckets. In this video, you’ll see how screening buckets can be used diversely for various purposes, such as screening soil, wood material, peat, and sand.

Gallery

Images of Screening Buckets

Explore our Screening Buckets photo gallery to see a wide variety of Vipermetal screening buckets in action. The images showcase their use in different applications, including versatile earthworks projects, compost handling, soil and biomaterial processing, and waste treatment. Discover how our screening buckets perform in real-world screening and material handling tasks.

Screening Bucket Base Machine, Blade Options, Accessories and Customization

Vipermetal Screening Bucket for Excavators, Wheel Loaders, Mini Excavators, and More

At Vipermetal, we prioritize providing a versatile range of screening buckets to suit a wide variety of machinery and applications. Our extensive selection of screening buckets is one of the broadest on the market, with options specifically designed for excavators, wheel loaders, mini excavators, and other types of loaders. Each model is engineered to adapt to different machine sizes and operational requirements, ensuring optimal performance on any construction site.

Find the Perfect Vipermetal Screening Bucket for Your Machinery

Choosing a Vipermetal screening bucket means finding the ideal solution for your specific machinery and working environment. Our screening buckets are built to be compatible with various machine technical specifications, allowing you to maximize efficiency and safety in your material handling tasks.

Durable and High-Performance Screening Buckets for Demanding Conditions

Vipermetal screening buckets are designed to deliver exceptional durability and performance in even the toughest conditions. Whether you’re involved in earthmoving, material handling, or other demanding projects, our screening buckets offer the precision and flexibility needed to achieve superior results.

Blade Options for Screening Buckets – Optimize Screening Efficiency

Within our extensive range of blade models, you’ll always find the perfect shape for your needs. We offer versatile blade options that excel in various applications such as screening, light crushing, mixing, bio-aeration, and stabilization.

Each blade model is available in different spacings, precisely influencing the particle size of the screened material, ensuring accurate adjustment and an optimal outcome.

Screening bucket can be customized and tailored entirely to meet your needs

We can equip the screening bucket with your preferred blade models, accessories, and features to perfectly align with your operational requirements. If necessary, we also make adjustments to the product’s structure and attachment methods based on your order.

Tailored to your specific preferences, we customize the screening bucket according to your special requests. We have the capabilities to accommodate unique needs and ensure that our screening buckets meet even the most specific customer requirements.

Vipermetal’s customized screening buckets provide a perfect fit and optimal performance. You can trust that you’ll receive a screening bucket that precisely meets your needs and enhances your operations.

Accessories and Attachments for Screening Buckets

Vipermetal’s range of accessories and attachments are designed to enhance efficiency, versatility, and durability in various working conditions.

These additional components provide significant flexibility and adaptability in handling different materials while adding reliability and safety to the operations

Ready to Discover the Perfect Screening Bucket for Your Project?

Our expert team is here to answer all your questions and provide you with detailed insights into our innovative screening buckets. We understand that every project is unique, and we’re committed to helping you find the ideal solution that meets your exact requirements.

With delivery available to nearly anywhere in the world, Vipermetal ensures that you get the right product no matter where your project is located. Reach out today and let us guide you to the best solution for your material handling needs!

Reach out to Vipermetal now! Let us guide you to the right screening bucket for your needs and explore tailored solutions to ensure your project’s success. Don’t wait—start optimizing your material handling today with Vipermetal. Your success starts here.

Contact Us Today!

Why choose a Vipermetal screening bucket?

A Vipermetal screening bucket is our passion and pride. Each model is meticulously designed to meet the rigorous demands of professional use, making it an ideal choice for a wide range of material handling tasks. Our screening buckets are developed in close collaboration with industry professionals, ensuring that every detail reflects valuable insights and real-world experience.

Tested for Durability and Performance in All Conditions

At Vipermetal, we take quality seriously. Our screening buckets undergo extreme testing in our dedicated testing area, where we push their performance beyond typical usage scenarios. This rigorous evaluation ensures that every Vipermetal screening bucket delivers unmatched functionality and durability in any condition, from demanding construction sites to challenging material screening applications.

Vipermetal – Committed to Excellence in Screening Buckets

When you choose a Vipermetal screening bucket, you’re investing in a high-quality, reliable tool that is built to last. Our goal is to provide the best possible screening solutions for our customers, combining precision engineering with robust performance to meet the needs of professionals across various industries.

1

Efficiency in its own class

Vipermetal's screening buckets are renowned for their exceptional efficiency, setting them apart in the market. Their design and production employ top-notch technology and innovations, ensuring the best possible screening efficiency and crushing results. Whether it's soil screening, peat handling, or screening other aggregates, Vipermetal screening buckets guarantee excellent performance and efficient operations

2

Preferred by professionals

Vipermetal screening buckets have solidified their position as the preferred tools among professionals. Their high-quality, reliable performance coupled with durability makes them ideal for professional use. Their versatile features and customization options ensure they are perfectly suited for various tasks and work environments. When you choose a Vipermetal screening bucket, you can trust that you're opting for the professional's choice

3

Manufactured in Finland using the finest steel

Vipermetal prioritizes quality and durability in its manufacturing process. Only the finest steel grades are used in the production of our screening buckets. These materials ensure the longevity and durability of our products even in demanding conditions. Finnish expertise and precise craftsmanship are evident in every screening bucket, so you can trust that you are getting a high-quality and long-lasting product.

4

Good resale value

Vipermetal's screening buckets maintain an excellent resale value. Their high quality, durability, and renowned efficiency make them sought-after products in the market. If you decide to upgrade or switch your screening bucket in the future, you can trust that Vipermetal's good resale value will ensure you get the best return on your investment.

What Is a Screening Bucket Used For?

A screening bucket is a versatile tool widely used in various material handling and processing tasks. It is most commonly utilized for screening soil, peat, bark, and biomaterials, making it an essential tool in landscaping, construction, and recycling. Screening buckets are also ideal for backfilling excavations, light crushing tasks, and separating materials on-site.

How Does a Screening Bucket Work?

The rotating screening blades of a screening bucket play a crucial role in achieving an efficient and precise screening process. This design ensures high-quality results without compromising speed, allowing users to separate and process different materials effectively. Using a screening bucket promotes better recycling and reuse of materials, supporting a more environmentally friendly and sustainable approach to work.

The rotating screening blades of the screening bucket are crucial to achieving an efficient screening process without compromising quality. Using the screening bucket enables better recycling and reuse of materials, thereby contributing to an environmentally friendly approach to work.

Primary Applications of Screening Buckets

Screening Soil and Organic Materials

Ideal for landscaping and agricultural tasks, screening buckets can separate soil from debris, improving soil quality and preparing it for reuse.

Recycling and Waste Management

Screening buckets help in processing recyclable materials and separating waste, contributing to a circular economy.

Backfilling and Light Crushing

Perfect for backfilling excavations and light crushing of materials, making it a versatile addition to construction and demolition sites.

Handling Biomaterials and Peat

Efficiently screens organic materials like bark, peat, and compost for various applications.

Unlock the Full Potential of a Screening Bucket

The possibilities for using a screening bucket are diverse, with applications across numerous industries. While it is commonly used for screening soil and organic materials, its potential extends far beyond, limited only by your imagination. A screening bucket is a reliable and efficient solution for various material processing needs.

Here’s some additional information on the primary applications of the screening bucket:

Soil Screening

Screening Soil with a Screening Bucket

Screening soil with a screening bucket is a crucial step in ensuring high-quality soil for various applications. This process is essential for creating an optimal growing medium that provides plants with the nutrients they need to thrive. Using a screening bucket allows for precise filtration, effectively removing stones, clumps, debris, and weeds, which results in cleaner, more suitable soil for planting.

The screening process also enables the addition of soil enhancers, such as peat or sand, to improve the soil’s characteristics, making it ideal for landscaping, gardening, planting, or turf preparation. By customizing the soil composition during screening, the screening bucket ensures the final product meets the specific requirements of each project, from residential gardens to professional landscaping.

Screening soil with a screening bucket guarantees the removal of impurities, resulting in a high-quality growing medium that supports healthy plant growth. This efficient tool not only ensures precise soil filtration but also provides the flexibility to adapt the soil for different applications, making it a valuable asset for soil preparation.

Peat Screening

Screening Peat with a Screening Bucket

Screening peat with a screening bucket is essential for achieving uniform quality and preparing the peat for further use. By effectively removing roots, stones, clumps, and debris, the screening bucket ensures the peat is consistent in purity and quality. This results in easier and safer loading, transportation, and handling of the screened peat for various applications.

The versatility of the Vipermetal screening bucket, with its multiple blade options and adjustable spacing, enables efficient and precise screening. This ensures the production of peat that meets specific requirements for different uses, whether in agriculture, energy production, or gardening. The rapid and thorough screening process not only guarantees high-quality peat but also leads to significant cost savings by increasing productivity.

Peat serves a variety of purposes across multiple sectors, including heat energy production, agricultural applications as bedding and odor control, composting, gardening, landscaping, and as a growth medium for open-field cultivation. It is also used in soil improvement, oil spill management, green construction, and even in skincare products or peat baths. Screening peat with a screening bucket ensures that the processing is efficient and the end product is of high quality, ready for these diverse applications.

Screening Bark and Other Biomaterials

Screening Bark and Other Biomaterials with a Screening Bucket

Screening bark and other biomaterials with a screening bucket is a crucial process for efficiently separating desired materials from unwanted components. The Vipermetal screening bucket provides reliable and precise screening of bark, straw, hay, and various other biomaterials across different processes and industrial applications.

The versatile blade options and adjustable spacing features of the screening bucket allow for customized screening, ensuring that bark and other biomaterials are effectively separated from the surrounding material. The rotation and rotating screening blades deliver efficient screening, optimizing productivity and achieving the desired outcome.

Bark and other biomaterials serve as valuable raw materials in a range of industries, including bioenergy production, composting, soil improvement, and animal feed manufacturing. Additionally, they are utilized in various industrial applications. Screening these materials with a screening bucket ensures swift and reliable processing, resulting in cost-effective operations, increased productivity, and superior quality outcomes.

Earthworks and Light Crushing

Earthworks and Light Crushing with Screening Bucket

Vipermetal screening buckets are an excellent choice for earthworks and light crushing tasks. In these applications, the screening bucket demonstrates its efficiency and reliability, offering versatile solutions for handling various materials.

In earthworks, the screening bucket enables swift and precise filling tasks. It allows for the transfer and spreading of soil masses, aggregates, and other materials accurately to desired locations. The efficient screening feature of the bucket removes harmful stones and debris from the soil, resulting in a uniform final product and reducing the need for post-processing.

Effortless handling of light crushing tasks is also facilitated by the Vipermetal screening bucket. The optimized screening blades of the bucket allow for the separation of fine materials from coarser elements. This capability is particularly useful in tasks such as concrete screening or recycling construction waste. The screening bucket ensures accurate screening and delivers high-quality crushing results.

For more demanding crushing tasks, Vipermetal crushing buckets offer even more efficient solutions. These buckets are specifically designed for crushing robust materials like stones and concrete. They are robust and durable, enabling efficient crushing work even in demanding conditions.

The installation of the screening bucket

The installation and commissioning of the screening bucket require precision and careful attention. Before commissioning the screening bucket, it’s crucial to thoroughly familiarize yourself with the accompanying user manual and safety guidelines.

Prior to installing the screening bucket onto a new machine, ensure their compatibility. It’s important to verify that the lifting capacity of the host machine aligns with the technical specifications of the screening bucket. Additionally, the hydraulic system of the host machine must meet the requirements of the screening bucket’s features. Following installation, ensure that the quantity of hydraulic oil is adequate to achieve the necessary pressure.

Confirm the compatibility of the attachment points between the screening bucket and the host machine and securely join the mating parts. Once the screening bucket is connected and securely fastened, link the hydraulic system of the machine to the screening bucket. Simultaneously, it’s crucial to inspect the compatibility and condition of hoses and connectors. Clean and properly secured connectors are essential to ensure a tight connection.

After the screening bucket is in place, its operation must be thoroughly checked while adhering to safety instructions. It’s highly important to prevent pressures from exceeding maximum values. Additionally, it’s recommended to record flow rates and pressure values related to operations for future reference and troubleshooting purposes.

Correct installation and commissioning of the screening bucket ensure its safe and efficient operation. Diligent adherence and attentiveness during operation are key to achieving the best results.

Using a screening bucket

Using a screening bucket isn’t difficult if you’re already familiar with operating the base machine. Practices and fine-tuning related to the screening of various materials and aggregates are easy to grasp quickly. It’s always wise to apply common sense while using the screening bucket. Proper usage ensures successful work and a prolonged lifespan for the bucket, avoiding unnecessary maintenance and repairs.

Before starting actual work, always ensure the condition, maintenance, and safety aspects of the screening bucket. It’s also advisable to let the hydraulic oil warm up slightly before beginning actual usage. During operation, it’s essential to monitor that the power output remains at the level required for screening and that there are no disruptions in the screening bucket’s functioning.

When screening different materials, it’s crucial to consider their specific differences. Additionally, it’s important to note the effects of moisture on the material’s screening properties. Also, ensure the proper filling of the bucket—do not overfill it, as this might cause unprocessed material to spill over the edges, reducing the quality of screening.

While Vipermetal screening buckets are built to endure and filter various materials, it’s essential not to use the bucket for materials it’s not intended for. If the screening bucket is misused, causing the equipment to malfunction, we reserve the right to consider the broken product outside warranty terms.

After usage, clean the screening bucket from dirt and perform necessary maintenance. For long-term storage, choose a dry, clean area without direct sunlight and corrosive gases or elements that could damage the screening bucket.

We do not recommend self-made modifications to the functions or structure of Vipermetal screening buckets. If alterations lead to operational issues, the warranty may not cover resulting damages.

If you encounter any issues while using the screening bucket, feel free to contact us. We’re happy to assist our customers with queries and troubleshoot problems related to our products.

Be aware of the dangers and always prioritize workplace safety

When using a screening bucket, it’s crucial to ensure that no individuals are within the caution area, especially underneath the screening machine when it’s running. Diligent workplace safety should be each equipment operator’s personal responsibility, always striving to operate in a manner that doesn’t pose any harm or danger to themselves or bystanders. It’s essential to consider potential environmental factors and any other possible hazards associated with working with the screening bucket.

Things to consider when using the screening bucket:

- Follow instructions and adhere to restrictions.

- Comply with safety regulations.

- Ensure communication and necessary actions in case of accidents, incidents, or fires.

- Perform required inspection and maintenance procedures for the screening bucket.

- Ensure an unobstructed environment for working with the screening bucket and the machine.

- Consider potential environmental hazards, such as power lines, cliffs, water bodies, etc.

- Check the suitability of connectors and attachments.

- Provide adequate lighting when working in low-light or dark conditions

Additionally, do not entrust the screening bucket to an inexperienced user. Ensure proper guidance for the correct use of the screening bucket and the machine, and make sure that the individual can work with the screening bucket safely and effectively.

FAQ

Frequently Asked Questions about Screening Buckets – Screening Bucket FAQ

What is a screening bucket?

A screening bucket is a hydraulic tool designed to be used, for example, with excavators. Its purpose is to screen and separate particles of different sizes from materials. It’s commonly utilized in construction and earthmoving tasks.

Where are screening buckets used?

Screening buckets are often used for screening and classifying soil, gravel, sand, and other materials. They are employed in various settings such as construction sites, mines, and for agricultural purposes.

What are the advantages of using a screening bucket?

The use of a screening bucket saves time and labor by enabling rapid material screening. Additionally, it can help reduce waste by separating reusable materials. Screening buckets are also widely employed to enhance material properties.

How is a screening bucket maintained?

Regular cleaning, inspection, and repairing any damages constitute screening bucket maintenance. Usage manuals and manufacturer recommendations serve as good sources for maintenance guidelines. If you have questions about maintaining Vipermetal screening buckets, feel free to contact us.

What does ISO/SAE (m³) mean?

ISO/SAE (m³) is a standard referring to the volume of a screening bucket, denoting its capacity in cubic meters, adhering to the definitions of ISO (International Organization for Standardization) and SAE (Society of Automotive Engineers).

What does the screening area of a screening bucket mean?

The screening area of a screening bucket describes the space where the bucket efficiently sieves material. It depends on the bucket’s structure, mesh size, and other influencing factors. A larger screening area allows the handling and screening of a larger quantity of material at once.

What does the mesh size of a screening bucket mean?

The mesh size of a screening bucket refers to the distance between the blades in the bucket. The choice of mesh size affects the precision in sieving and separating particles by size and quality. A larger mesh size enables the passage of larger particles and higher capacity, while a smaller mesh size yields a finer screening result.

What does particle size mean?

Particle size refers to the size of particles in the material being screened. When selecting a screening bucket, it’s crucial to consider the particle size of the material to be screened because it affects how effectively the bucket sieves and separates particles of different sizes. The screening bucket should be suitable for sieving a specific particle size to achieve the desired screening result.

What is the capacity of a screening bucket?

The capacity of a screening bucket refers to how much material it can screen within a specific timeframe. The capacity varies based on the bucket’s operating principle, size, model, and the power of the machine.

How much do screening buckets cost?

The cost of a screening bucket varies depending on its size, quality, and manufacturer. Generally, prices range from a few thousand to tens of thousands of euros or US dollars.

What to consider when choosing a screening bucket?

There are several factors to consider when choosing a screening bucket, such as:

- Properties of the material being screened: Consider the size, density, moisture, and other characteristics of the material being screened. For instance, different types of materials require different screening buckets. Understand how the material behaves during screening and what screening results are needed.

- Intended purpose and requirements of the screened material: Determine why you are screening material and what kind of results are needed. For instance, in construction, there might be a need to screen and separate different sizes of aggregates according to certain standards. Understand the working environment and conditions, as well as the purpose of the screening, to choose a screening bucket that meets your needs.

- Characteristics of the base machine: Take into account the lifting capacity of the base machine, the tipping load with a fully loaded bucket, hydraulic system characteristics, and other technical constraints. Ensure that the chosen screening bucket is compatible with the base machine and meets the lifting capacity and hydraulic system requirements.

- Size and capacity of the screening bucket: Select a screening bucket that has an appropriate size and capacity for the working conditions. The screening bucket should be large enough to handle the amount of material being processed but should not be excessively large or heavy for the base machine’s performance.

If you have further questions regarding screening buckets, feel free to contact us. We are happy to provide additional information and guidance on selecting and using screening buckets!

Request a Price List or More Information Today!

Curious about the cost of our screening buckets or unsure which model is the perfect fit for your needs? Contact us now, and our expert team will gladly provide all the details you need. We’re here to help you choose the ideal screening bucket and offer customized solutions tailored specifically to your requirements.

With delivery available to nearly anywhere in the world, Vipermetal ensures that you get the right product no matter where your project is located. Reach out today and let us guide you to the best solution for your material handling needs!