Peat production is a multi-stage process

Peat originates from partially decomposed vegetation, and its production, screening, and processing are crucial stages in utilizing it as an energy source and soil conditioner. Production begins with the formation of peat bogs in moist conditions. Once peat has formed, it can be harvested using various methods.

During the processing stage, peat may undergo different processes depending on its intended use. For instance, in energy production, peat can be compressed into briquettes or pelletized, making it more manageable and easier to store. Additionally, peat can be utilized as a soil amendment, where it is processed differently to enhance soil structure.

In peat manufacturing, screening buckets can also be utilized to efficiently handle peat materials. These screening buckets enable the separation of peat from impurities like stones and plant residues, thereby improving the quality of the end product.

Solutions for Peat Production

Vipermetal specifically recommends these products for peat handling

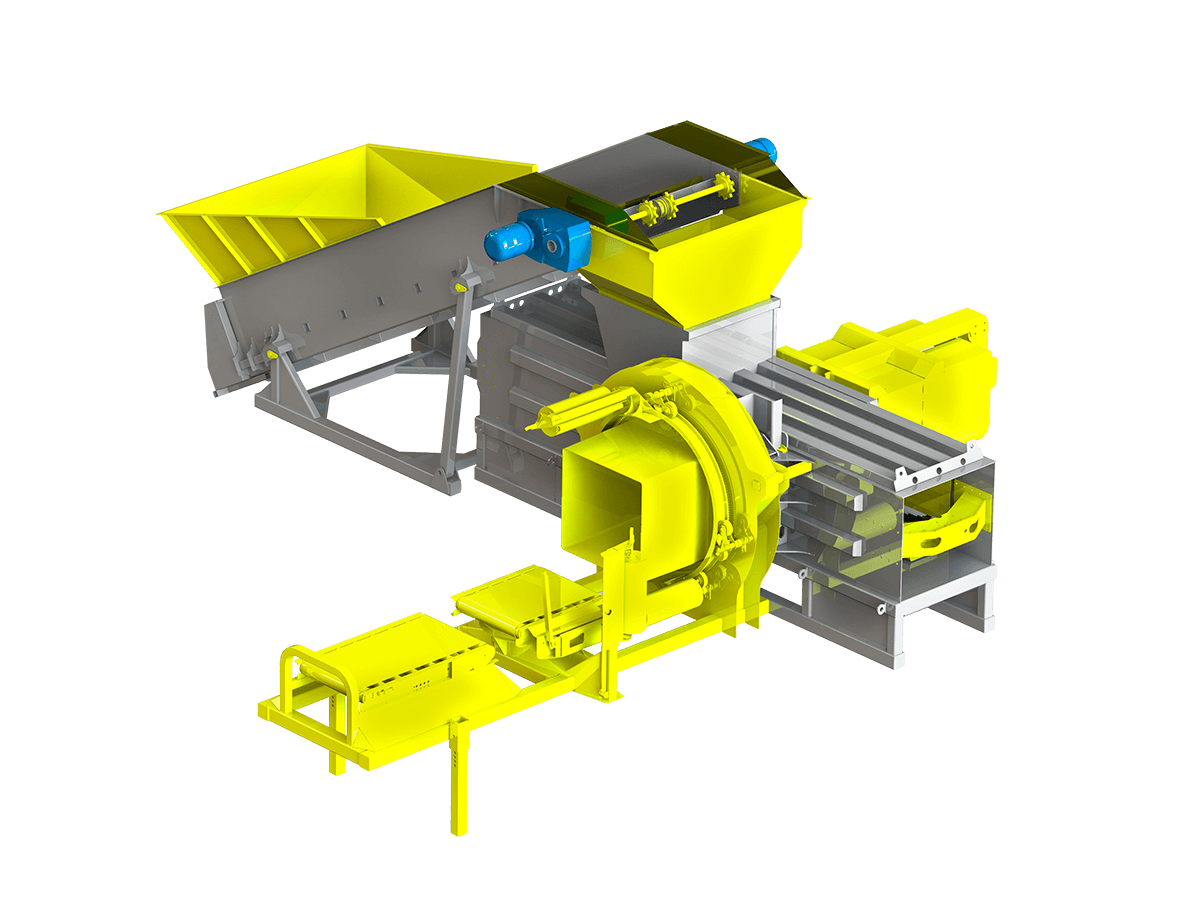

Vipermetal offers a comprehensive range of products suitable for peat production, screening, and similar tasks.

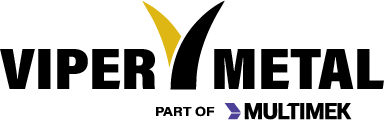

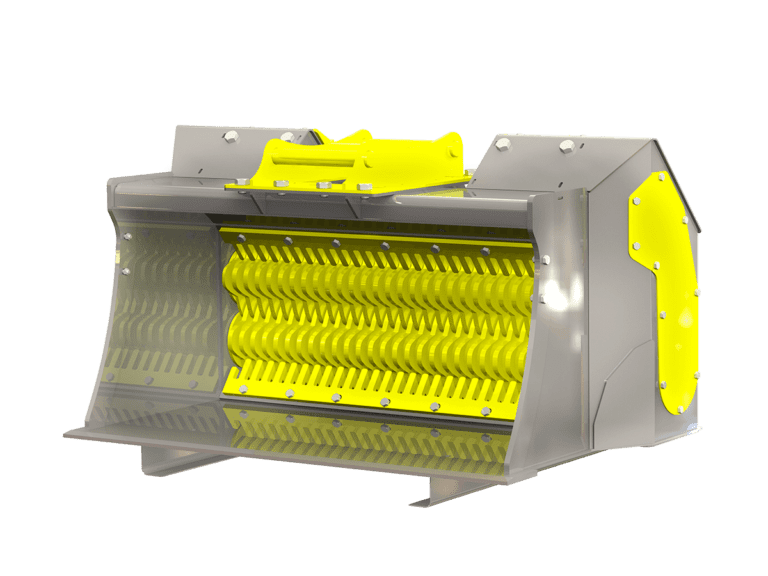

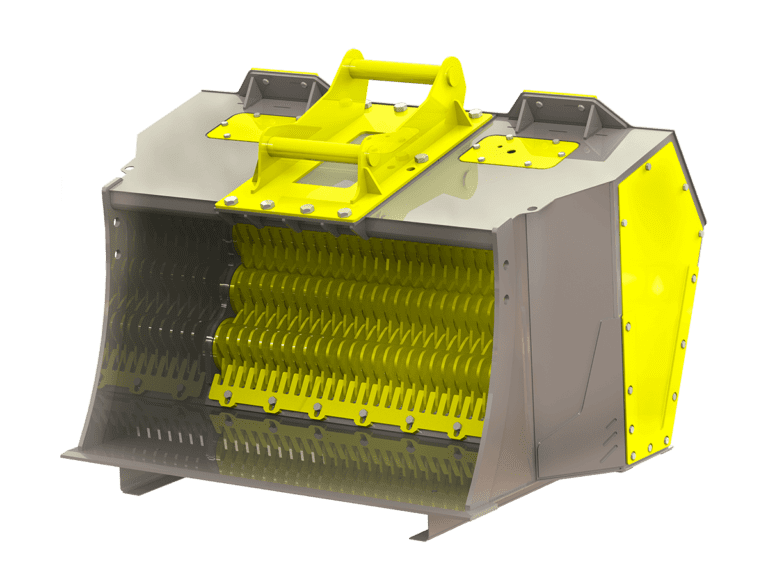

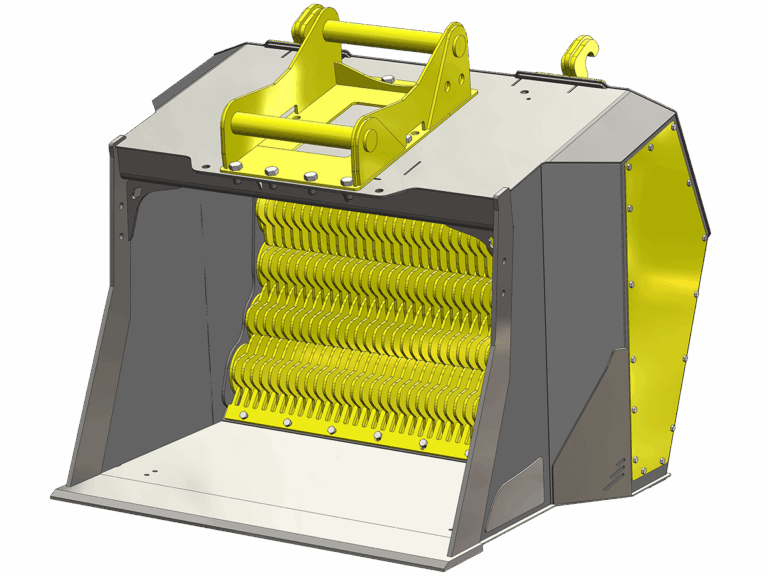

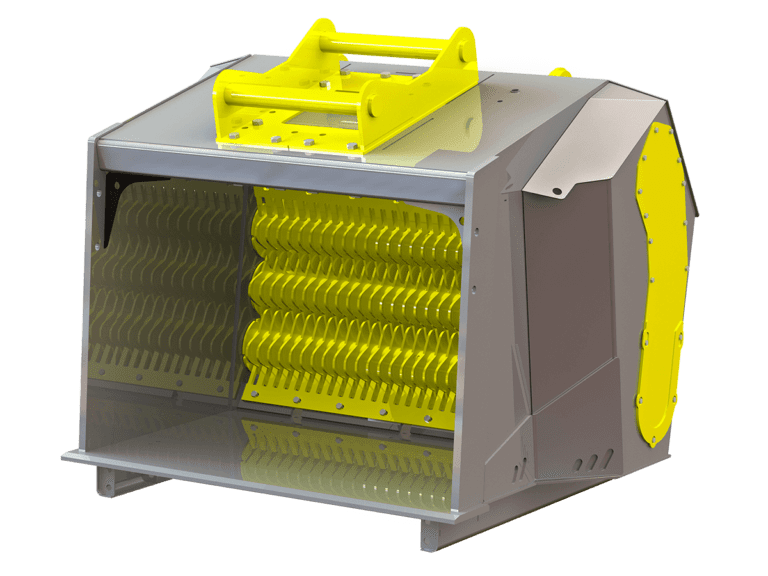

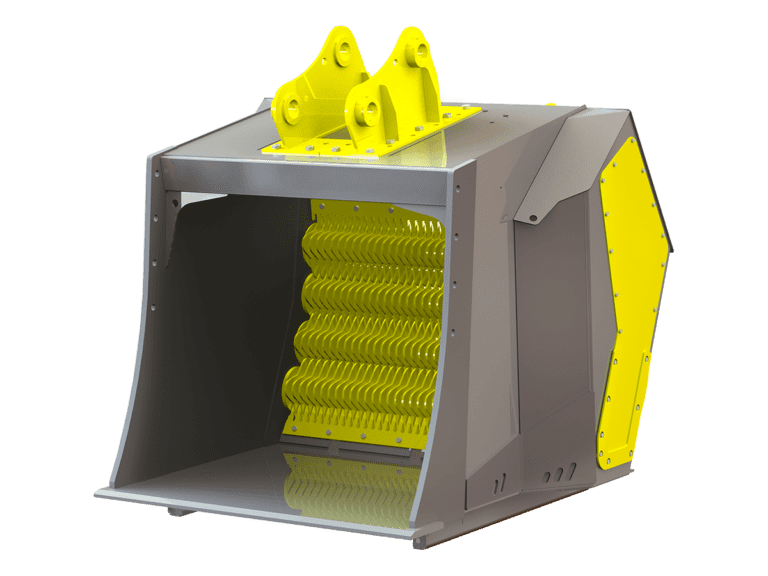

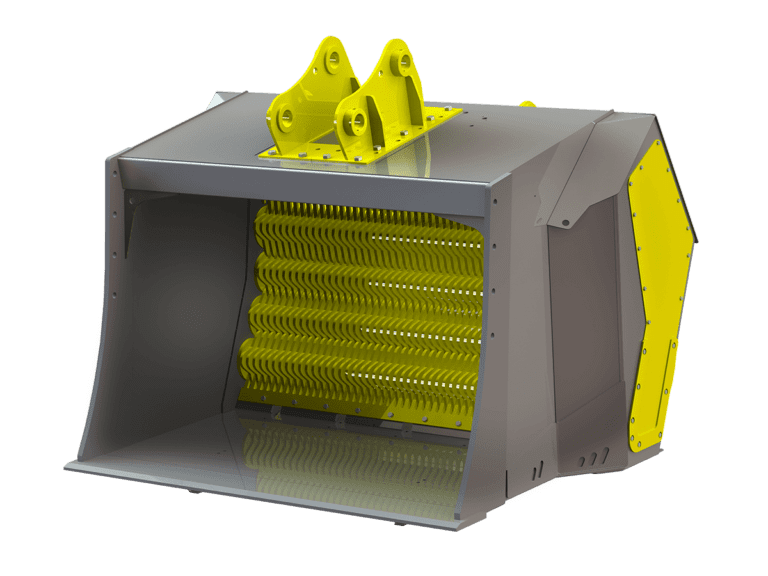

VPH 2-1500

Excavators: 8000-10000

Wheel loaders: 4000-7000

VPH 2-1500 is a popular screening bucket model designed especially for skid steer loaders and small excavators. This versatile screening bucket is excellent for screening and processing various types of materials.

Read moreVPH 3-1500

Excavators: 10000-15000

Wheel loaders: 7000-10000

VPH 3-1500 is a versatile high-quality screening bucket model that is suitable for various screening, processing, and also light crushing of different materials.

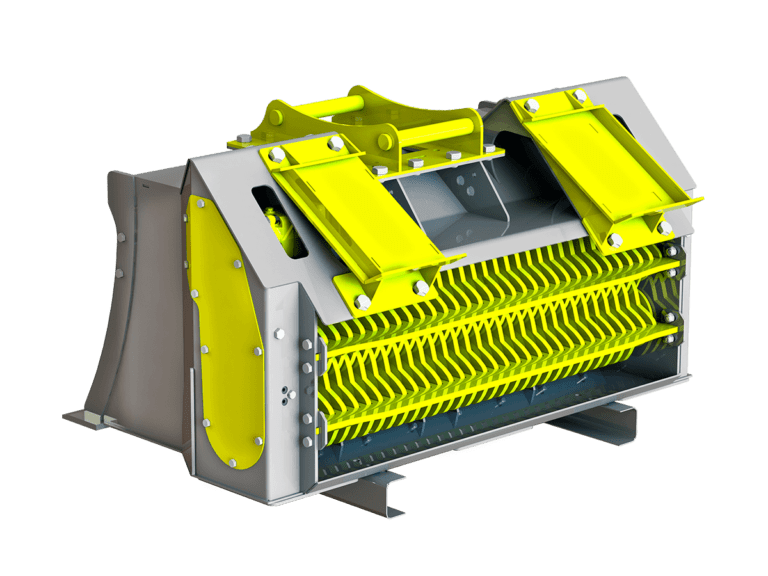

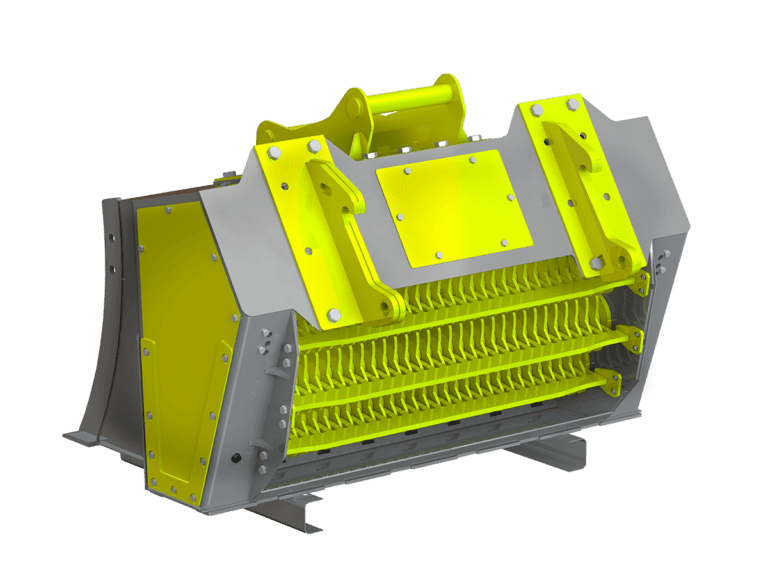

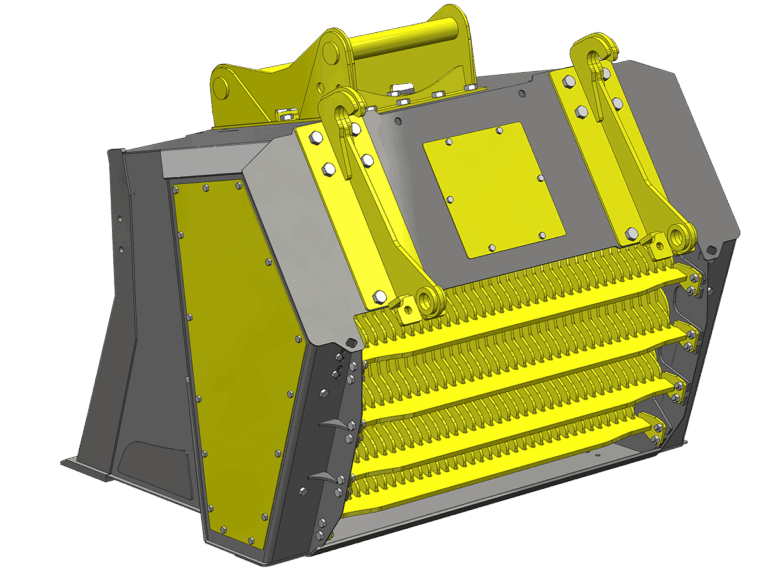

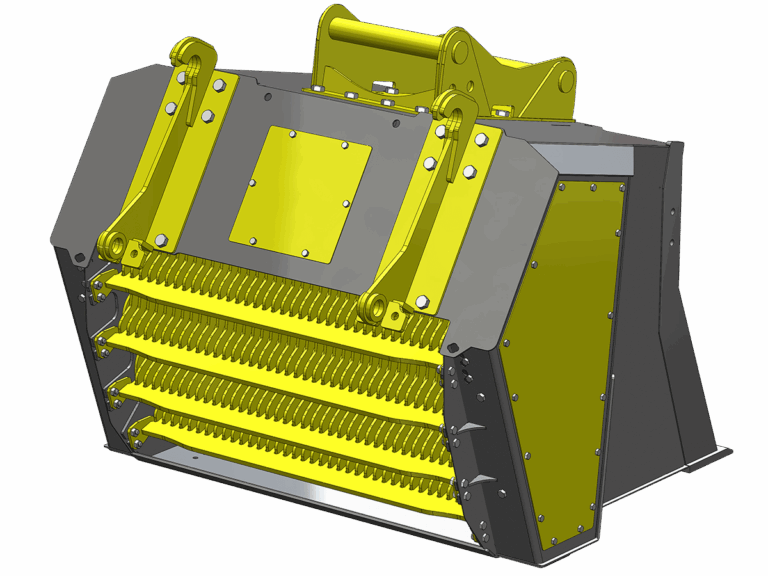

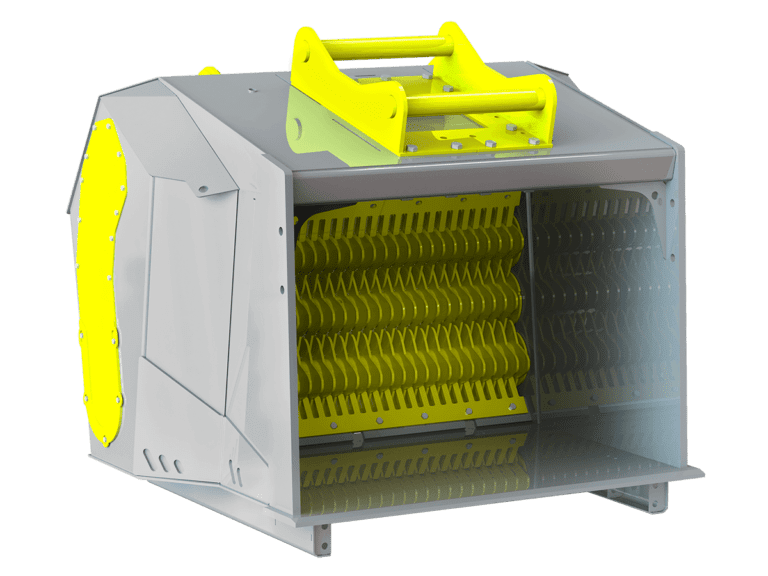

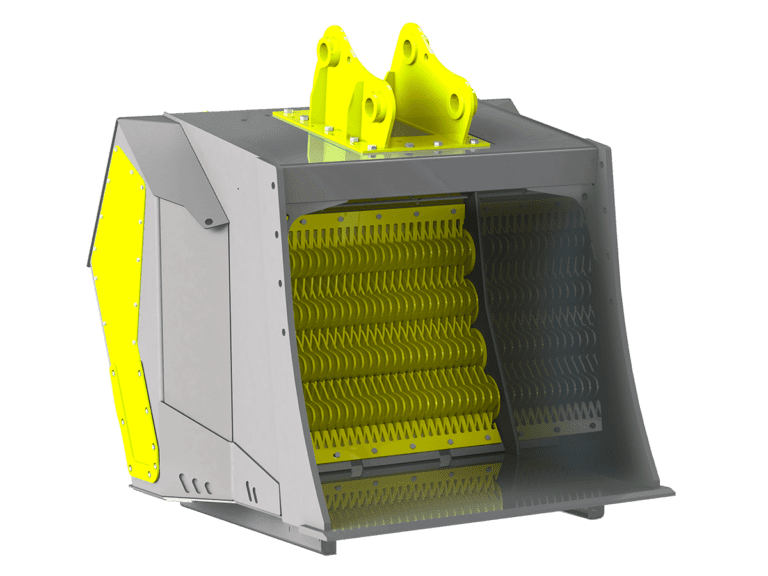

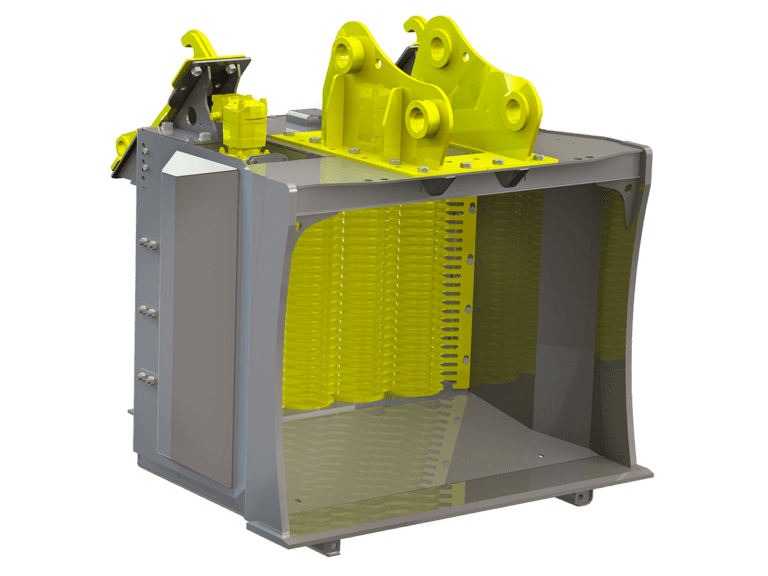

Read moreVPH 4-1502

Excavators: 14000-23000

Wheel loaders: 9000-15000

VPH 4-1502 is an updated version of the legendary 4-1500 model. Suitable for a wide range of machine sizes, both loaders and excavators. Available in a broad selection of optimized versions for fine screening, aeration, mixing, and light crushing.

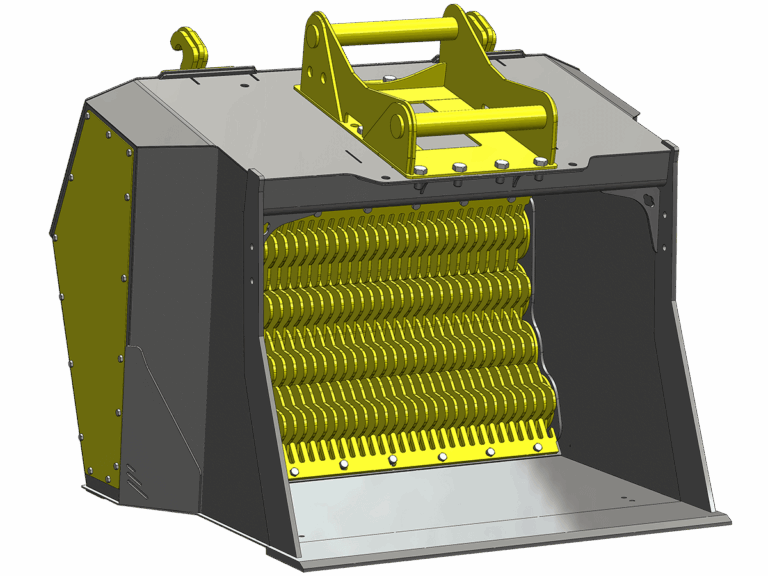

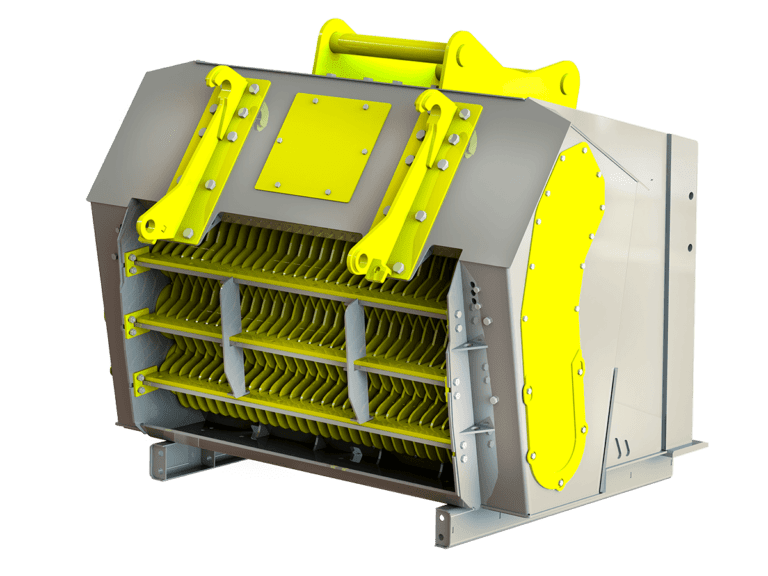

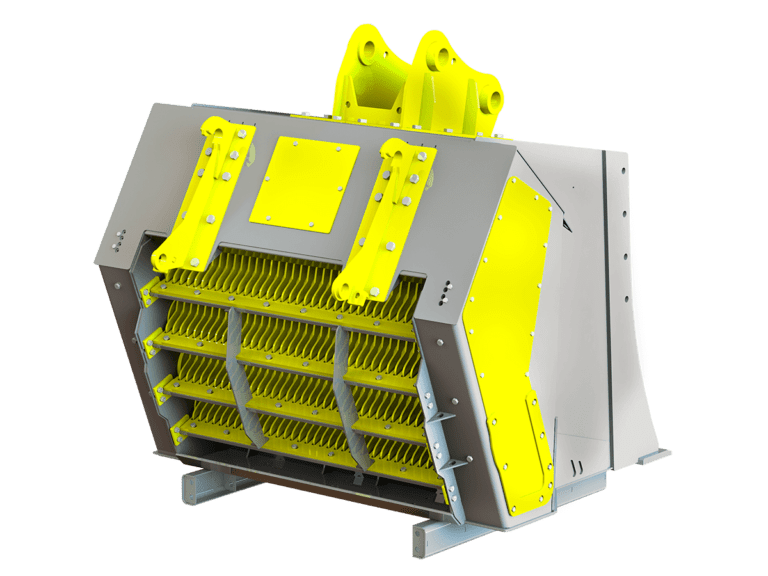

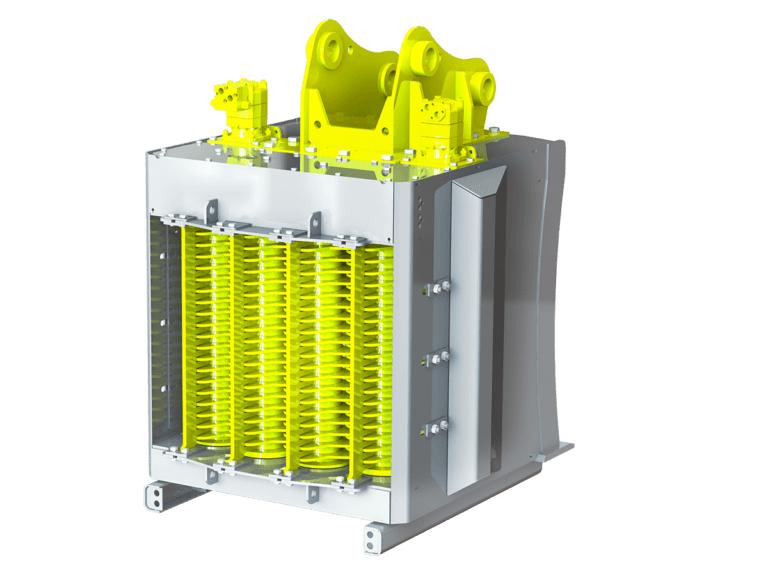

Read moreVPH 3-1700

Excavators: 22000-30000

Wheel loaders: 12000-16000

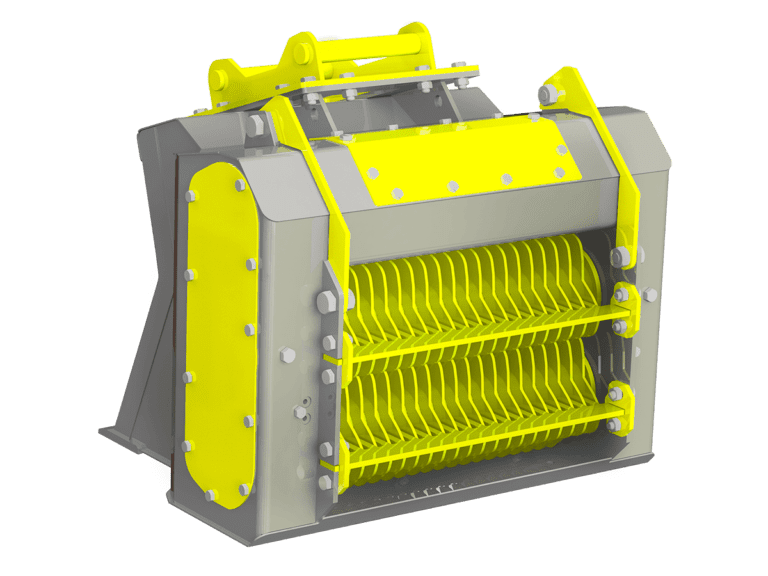

VPH 3-1700 is a robust and powerful screening bucket model favored by professionals. The model also offers versatile versions for fine screening, coarse screening, and even crushing.

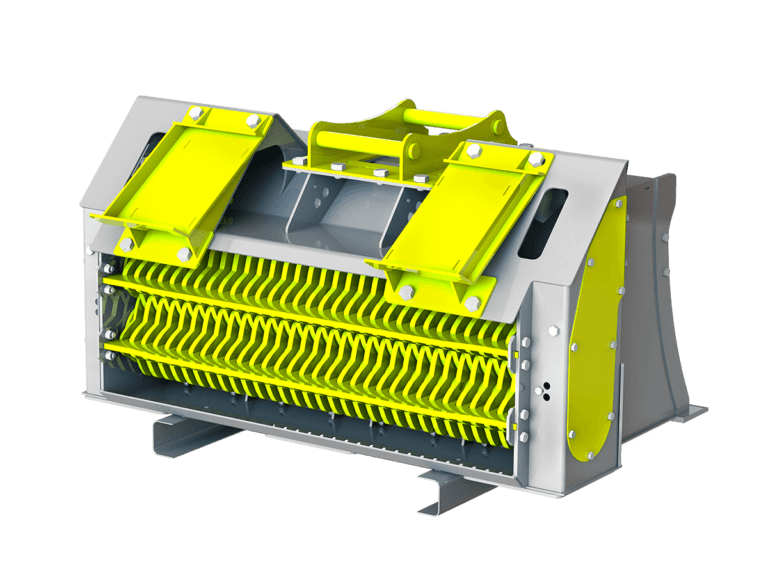

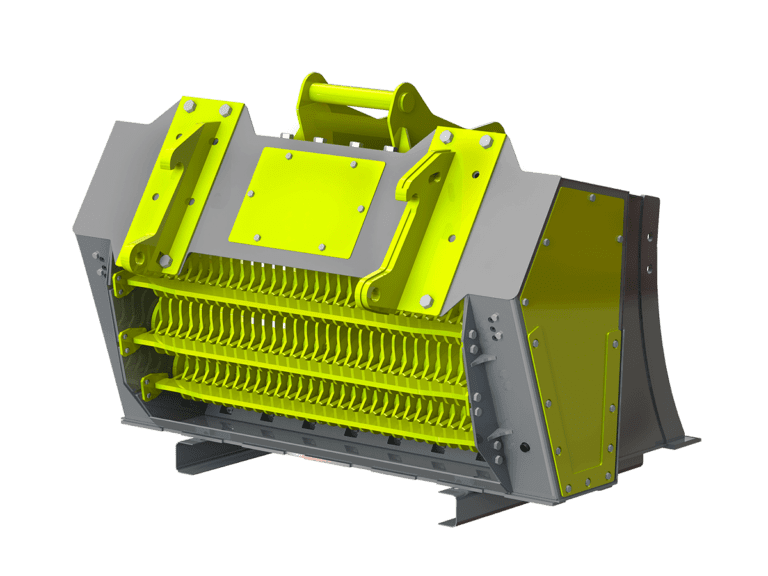

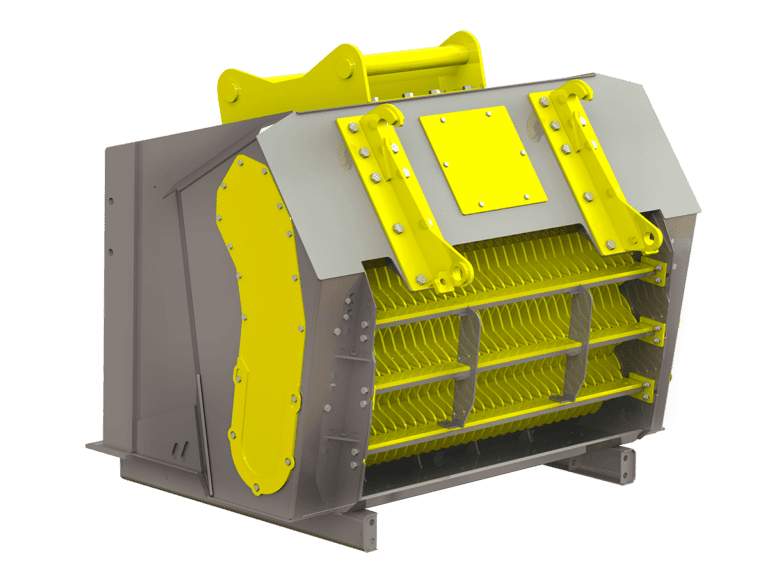

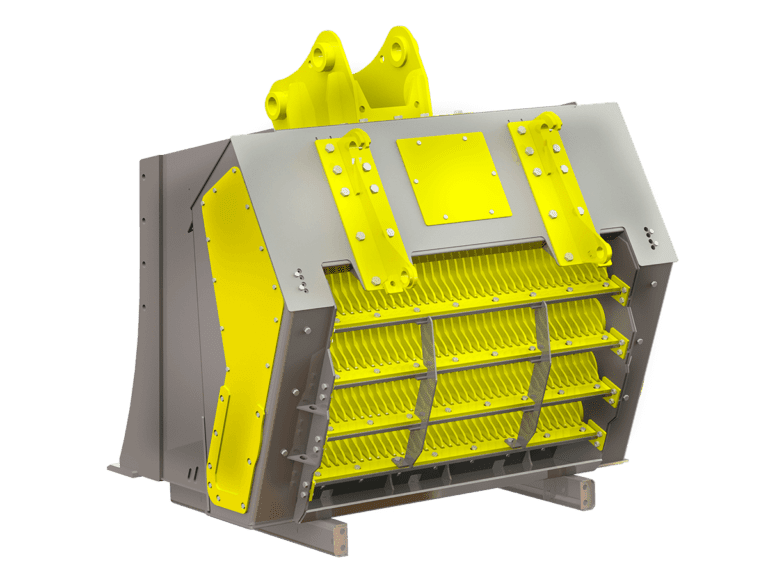

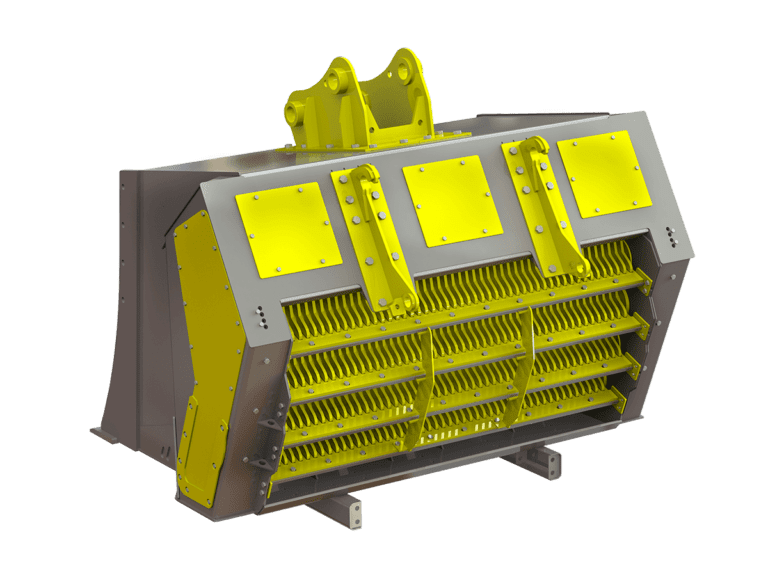

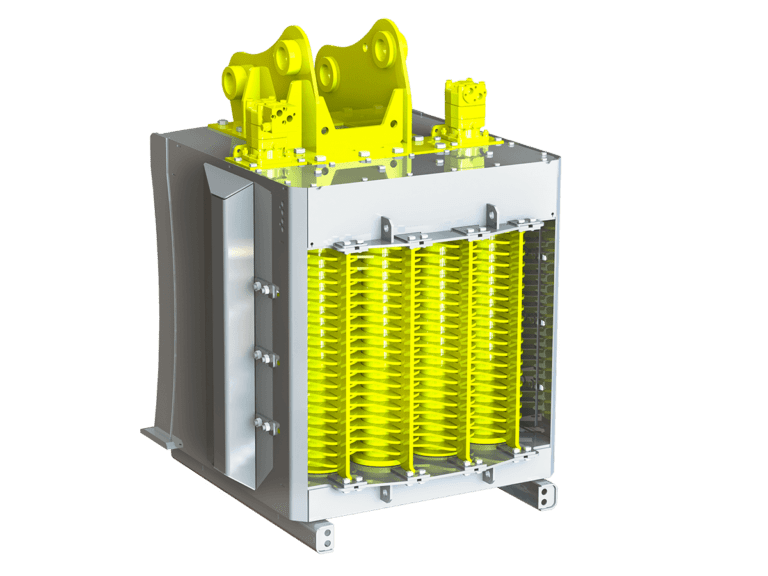

Read moreVPH 4-1700

Excavators: 24000-35000

Wheel loaders: 14000-20000

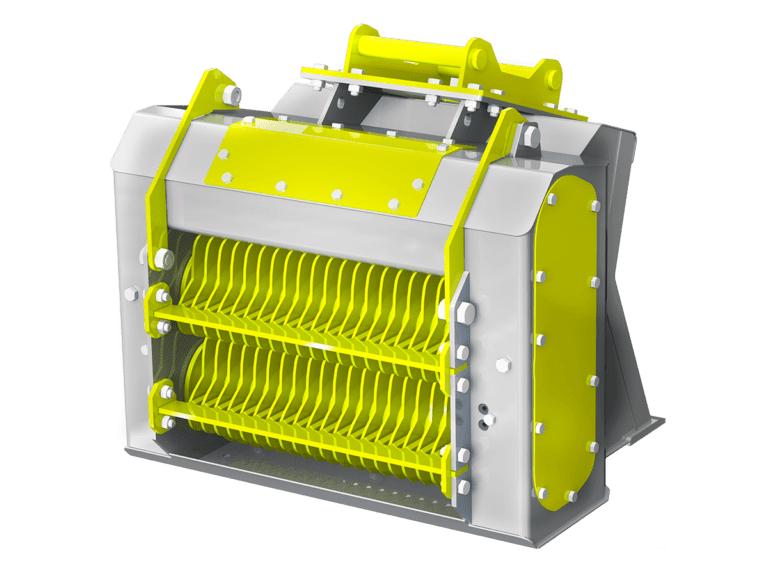

VPH 4-1700 is the big brother of the 3-1700 screening bucket model with four horizontal rotors for larger machine sizes. There are also several customized versions available for screening and crushing based on specific use cases.

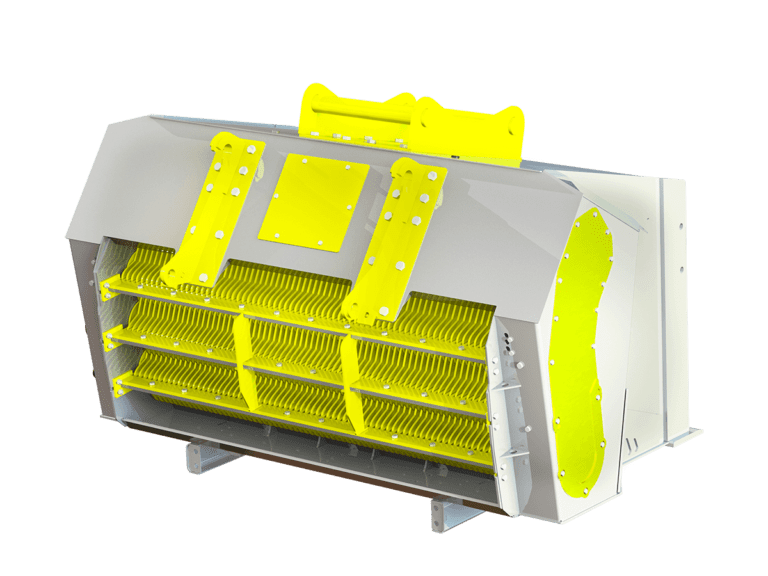

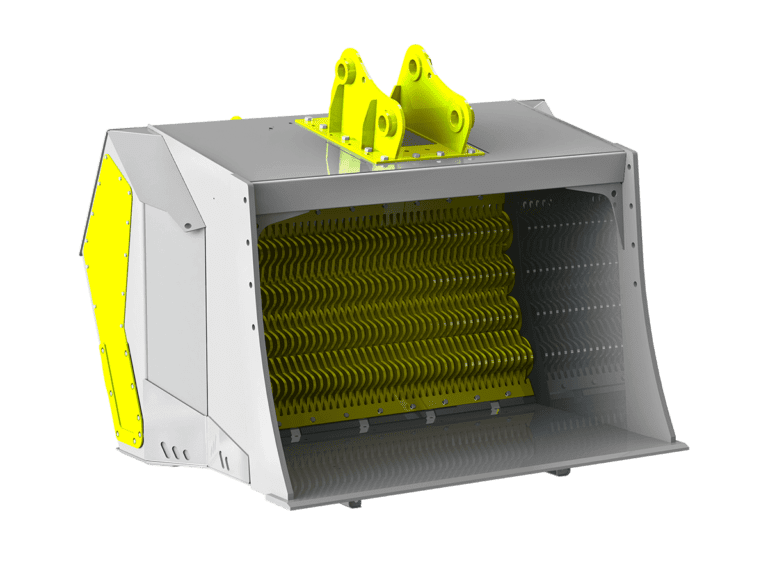

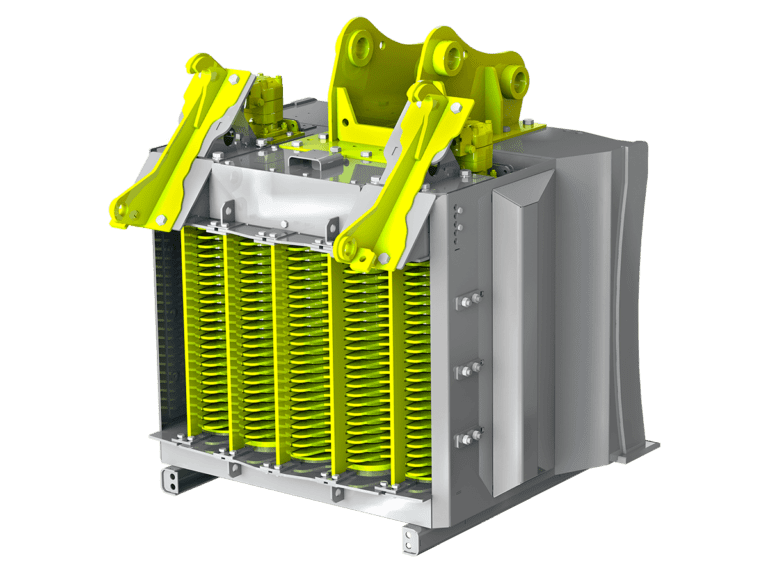

Read moreVPH 3-2300

Excavators: 28000-35000

Wheel loaders: 18000-25000

VPH 3-2300 is a high-capacity screening bucket for wheel loaders and excavators. Its versatile applications include widely used screening and mixing of materials such as peat, aggregates, and biomaterials.

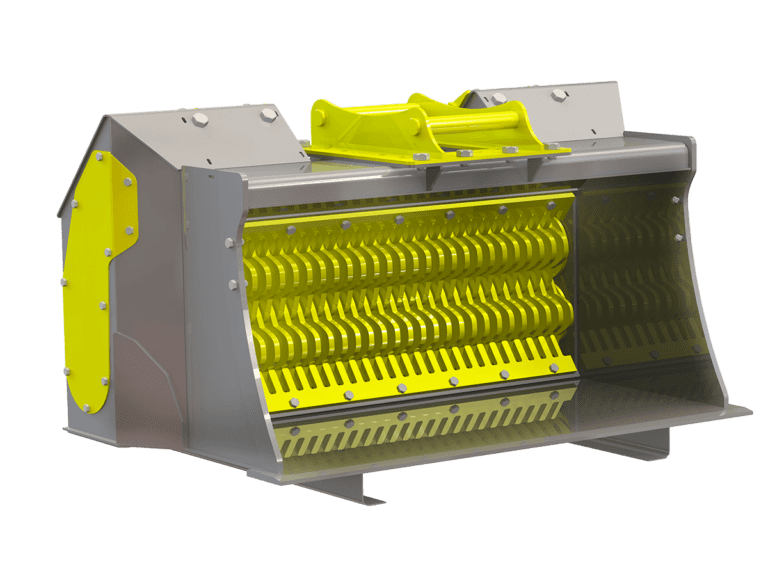

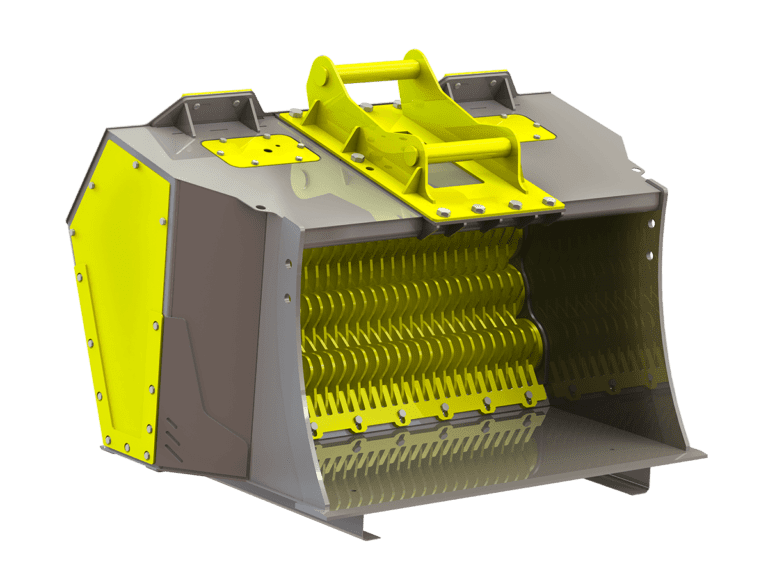

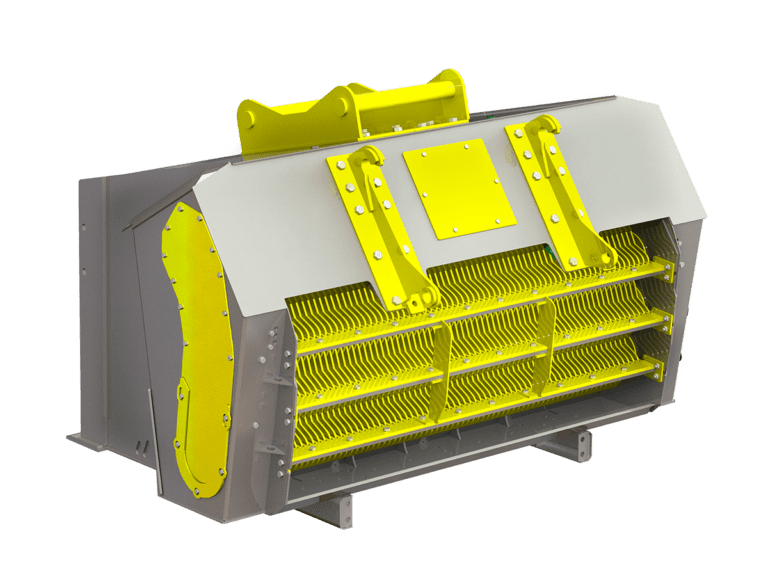

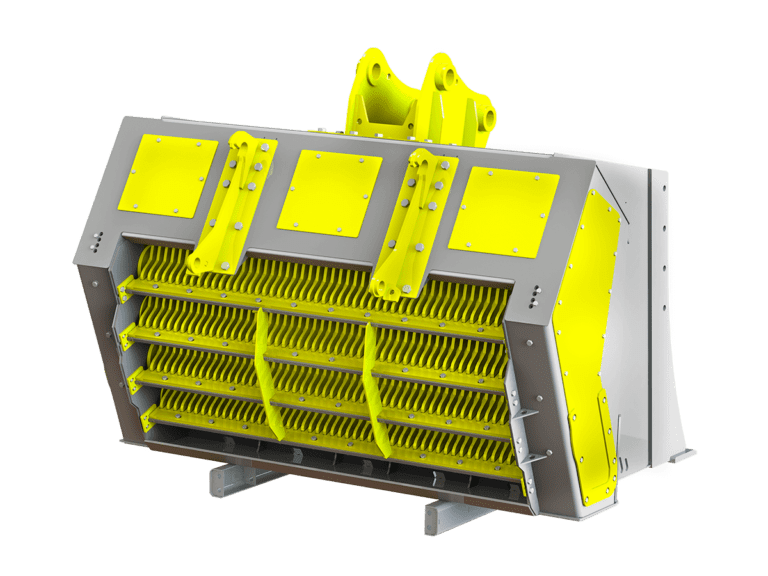

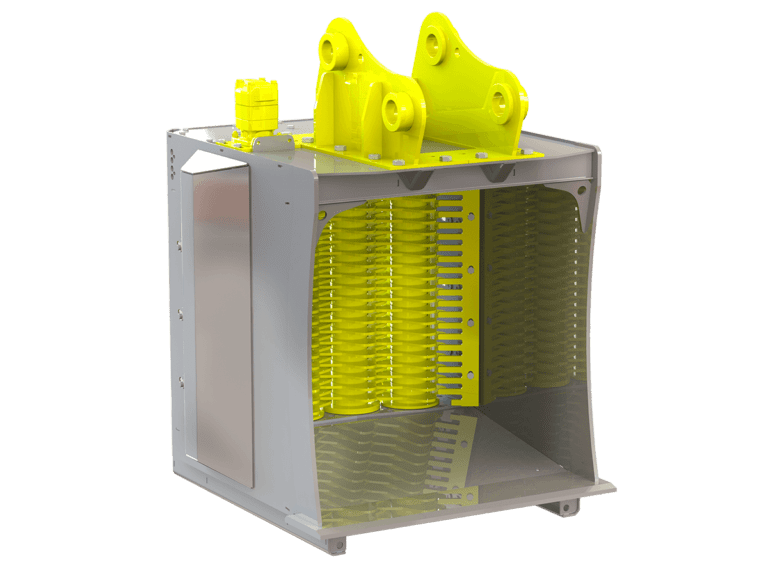

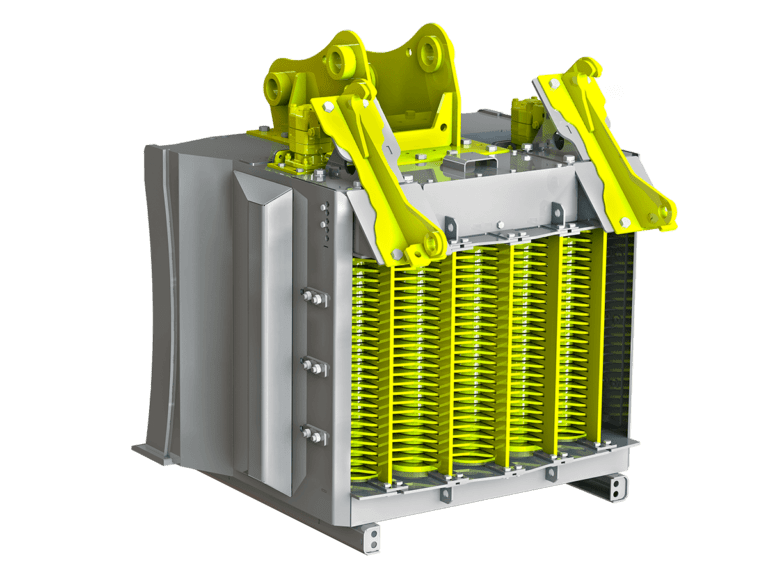

Read moreVPH 4-2300

Excavators: 32000-45000

Wheel loaders: 21000-30000

VPH 4-2300 is the flagship of the Viper screening bucket range. A powerful, high-capacity screening bucket designed for screening large volumes. With additional sides, the bucket volume can reach up to 5600

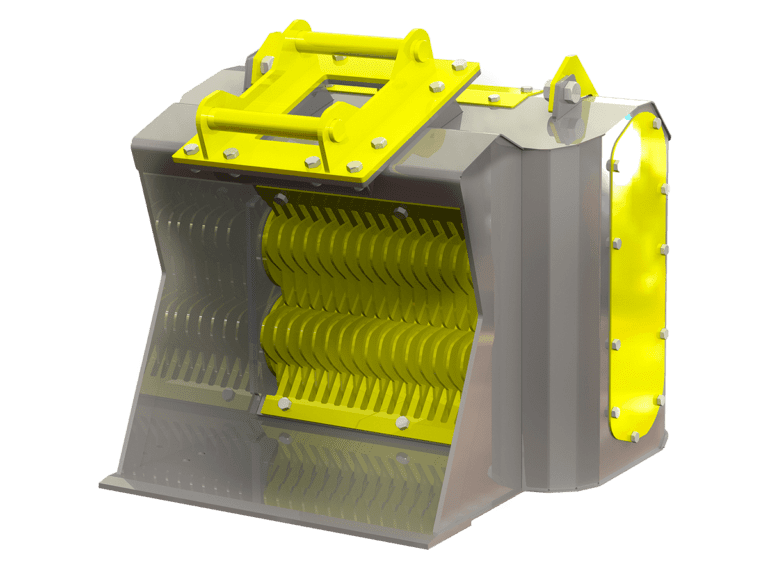

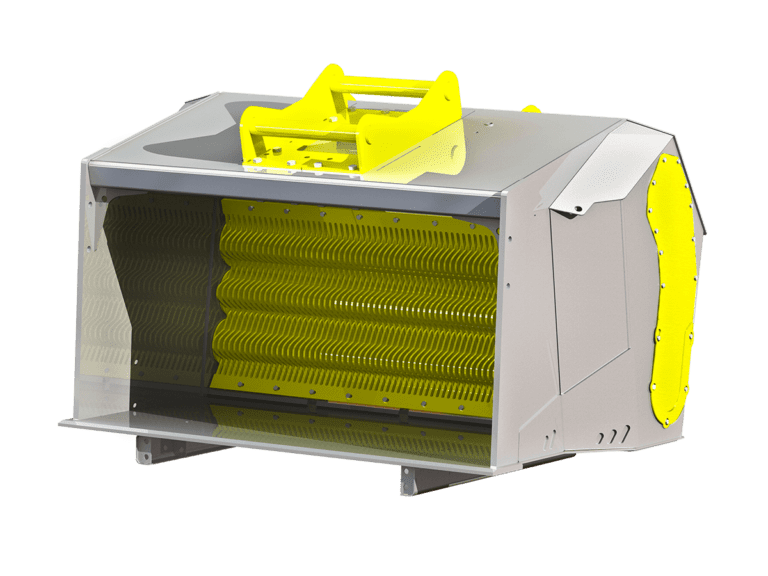

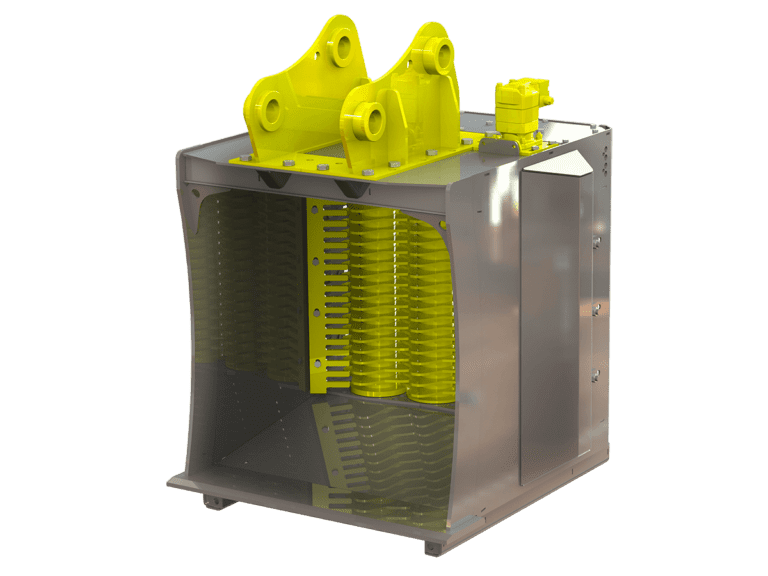

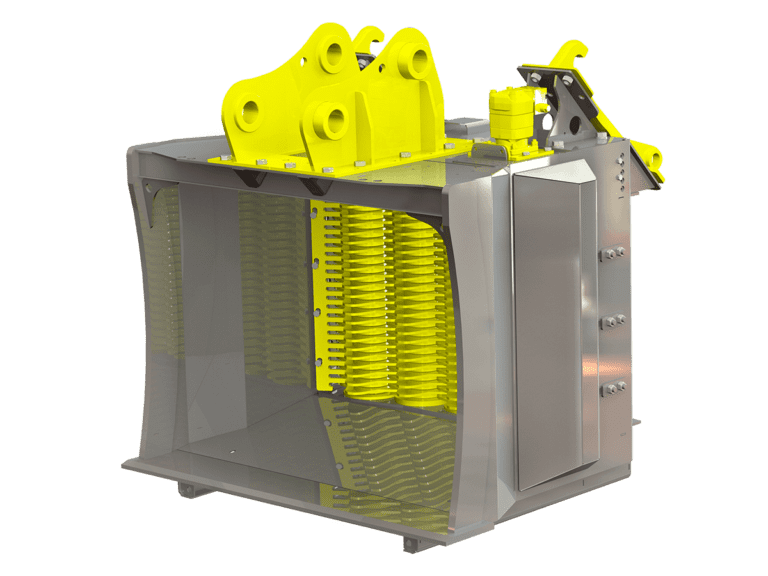

Read moreVPV 4-1100

Excavators: 14000-22000

VPV 4-1100 is a classic in the Vipermetal screening bucket range. This vertical drum model designed for excavators is an efficient and robust screening bucket for demanding use.

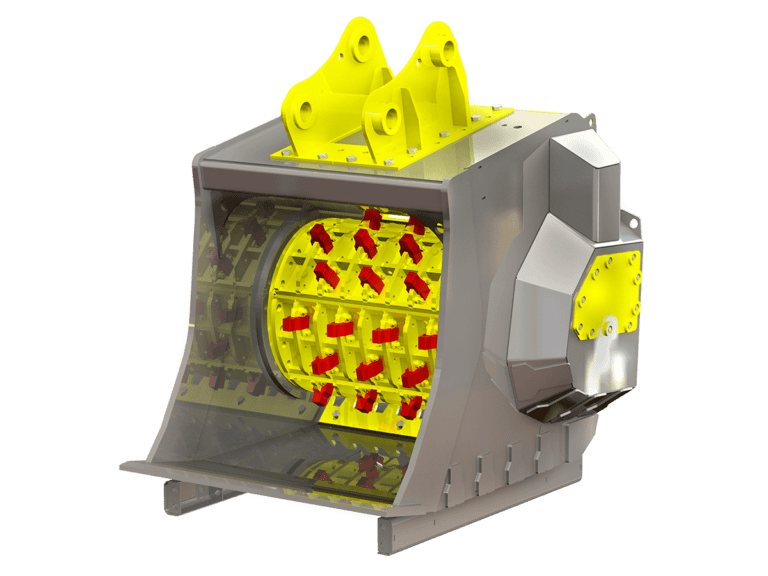

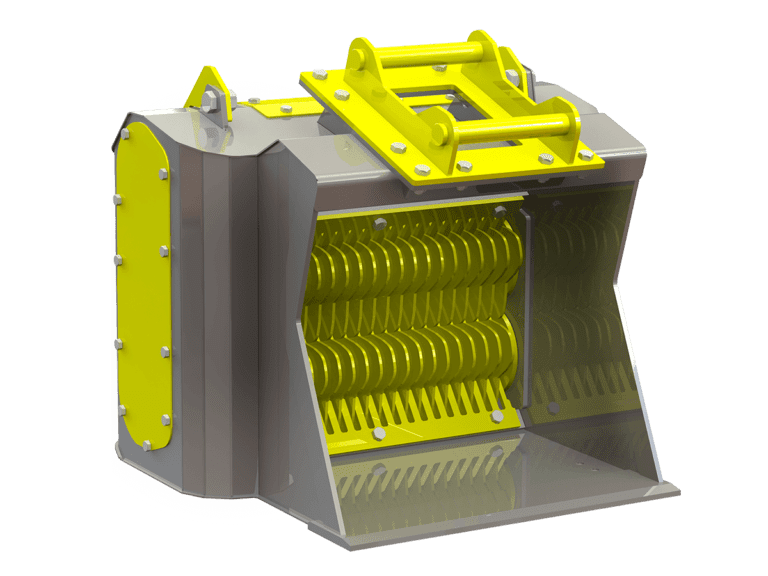

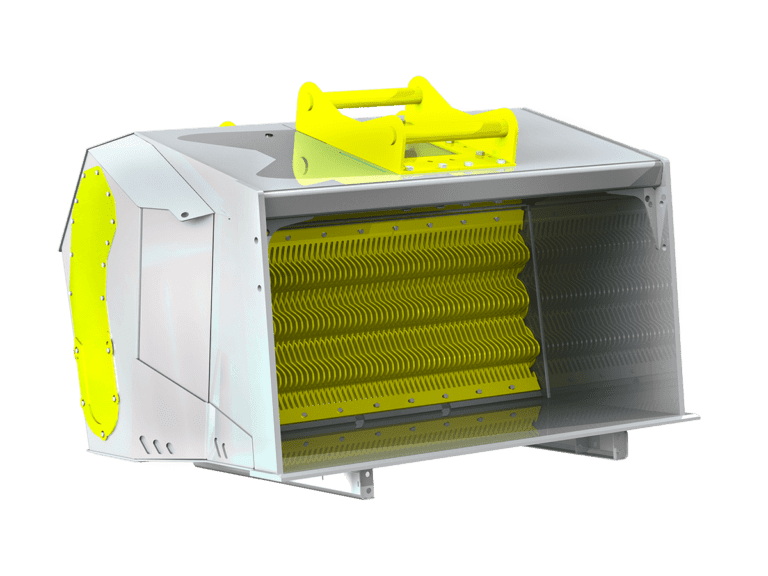

Read moreVPV 5-1350

Excavators: 20000-28000

Wheel loaders: 12000-16000

VPV 5-1350 is a vertical drum high-capacity screening bucket for various uses. Screening and crushing of aggregates are efficient with this bucket, favored by professionals.

Read moreVideo

Watch the video on peat screening

In this video, you’ll see the VPH 4-1500 screening bucket model handling peat. The VPH 4-1500 is suitable for a wide range of machinery sizes, from loaders to excavators.

Do you want more information about our products?

We’d love to tell you more about our products and help you find the best possible solution for any situation. Vipermetal’s services and solutions are designed to simplify and enhance your material handling. Our goal is to provide you with the best service that meets your specific needs. Whether it’s about sales, resale, product advice, or exchange machines, you can rely on Vipermetal’s expertise and quality. Feel free to contact us!