The crushing of coal is a crucial phase where the coal is broken down into smaller pieces suitable for fuel or other industrial use

The processing of coal often begins with mining, where coal is extracted from the earth’s surface or underground mines. It is then transported and processed differently based on its intended final use.

During the crushing process, coal is ground and fragmented into various-sized pieces to make it suitable for use in furnaces or energy production plants. This process can be conducted using various crushers or grinders depending on the desired end result.

Coal handling and crushing are pivotal in ensuring that coal is transformed into optimal fuel or raw material for industrial needs. Properly planned and executed processing stages ensure the highest possible energy density and suitability of coal for various applications.

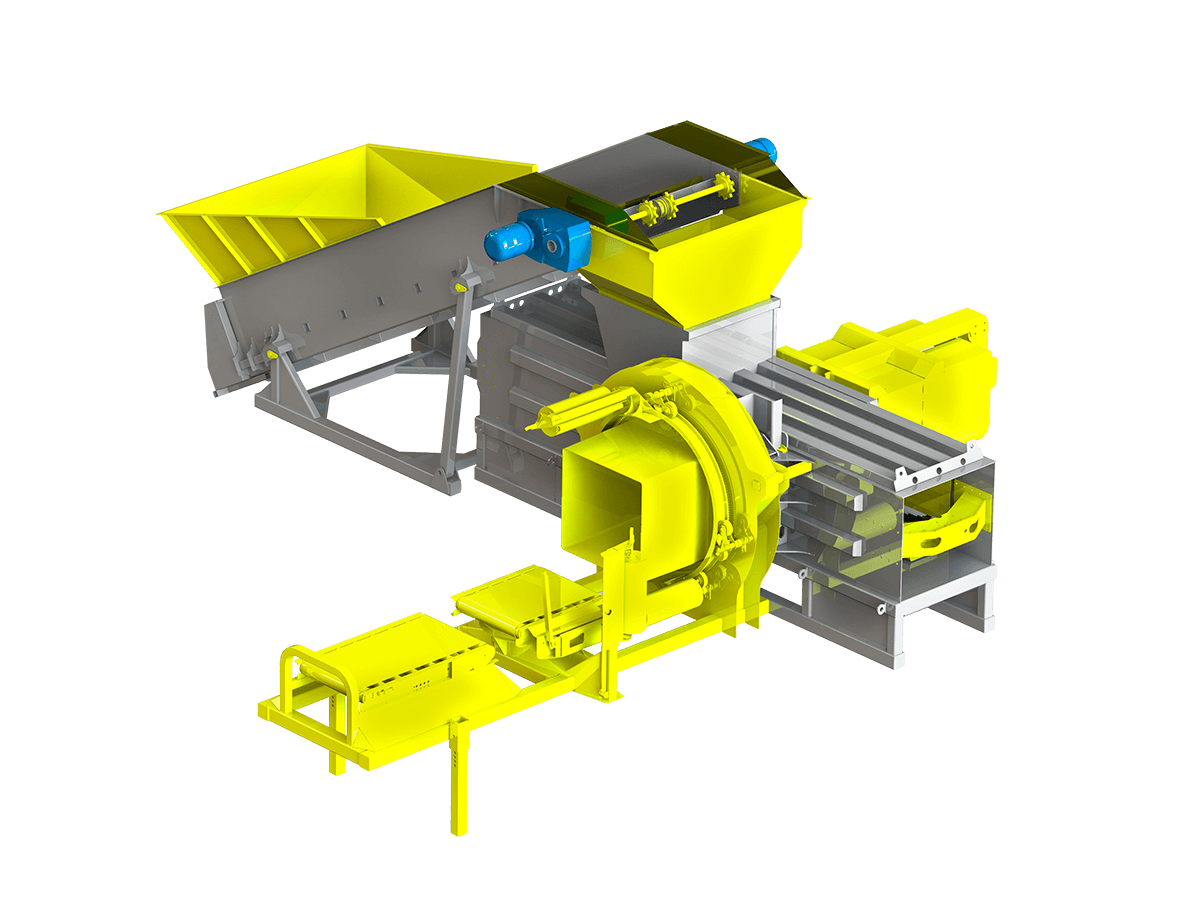

Solutions for crushing coal

Vipermetal specifically recommends these products for crushing coal

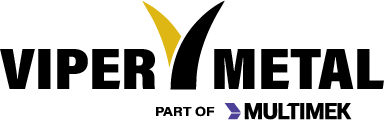

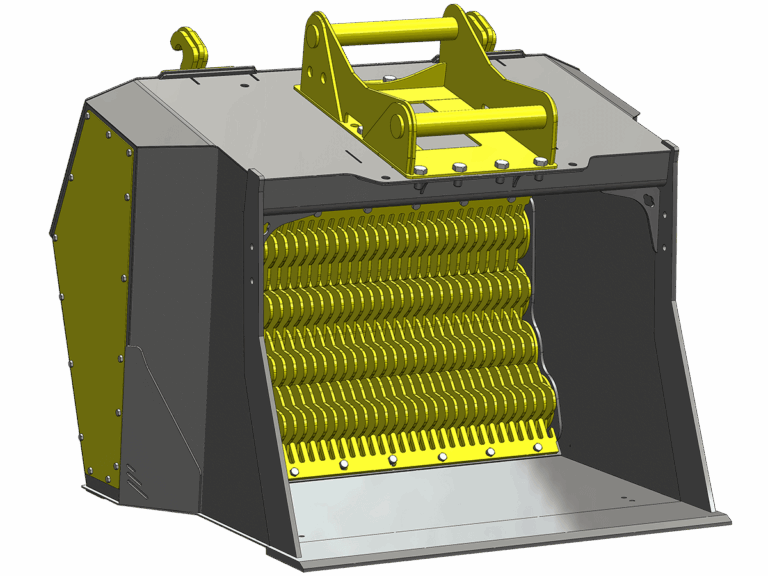

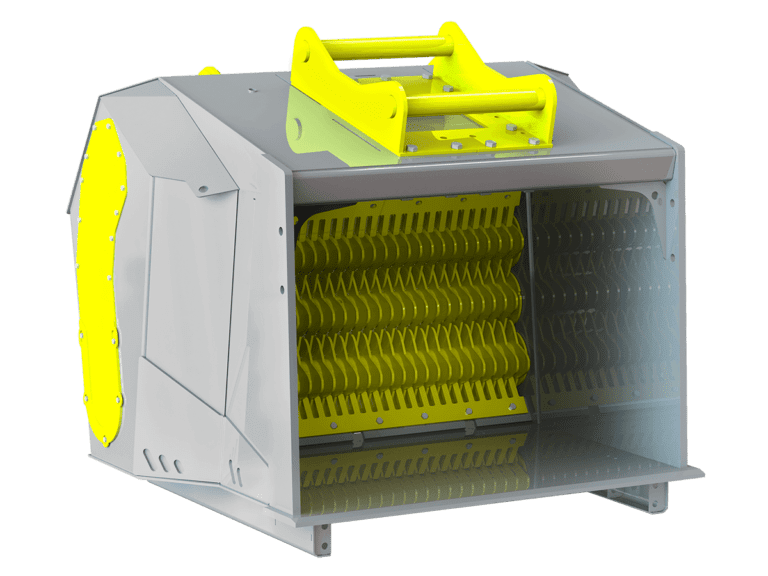

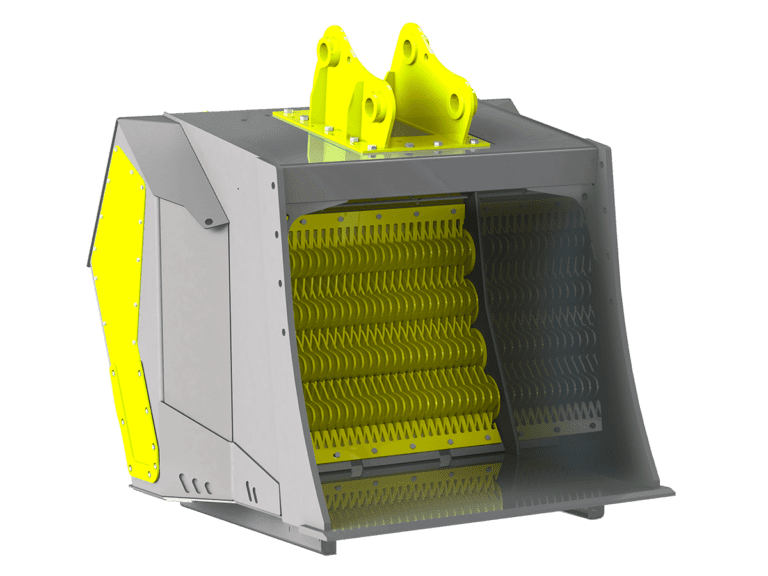

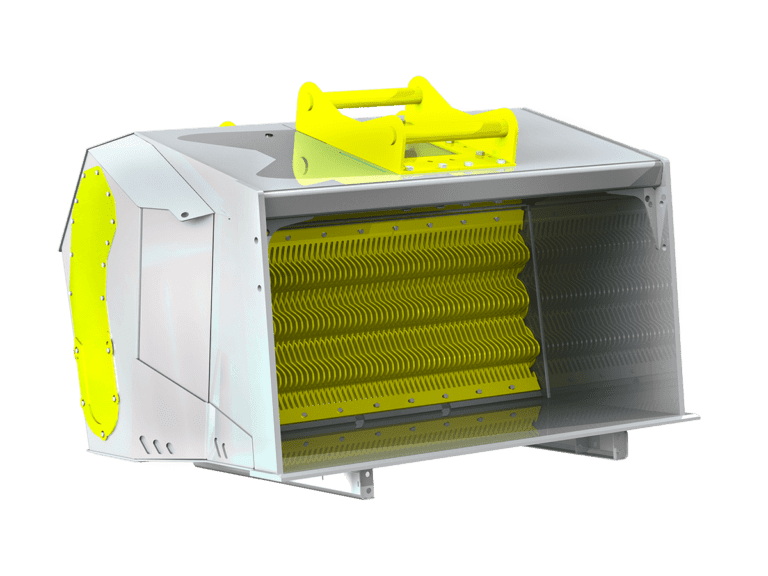

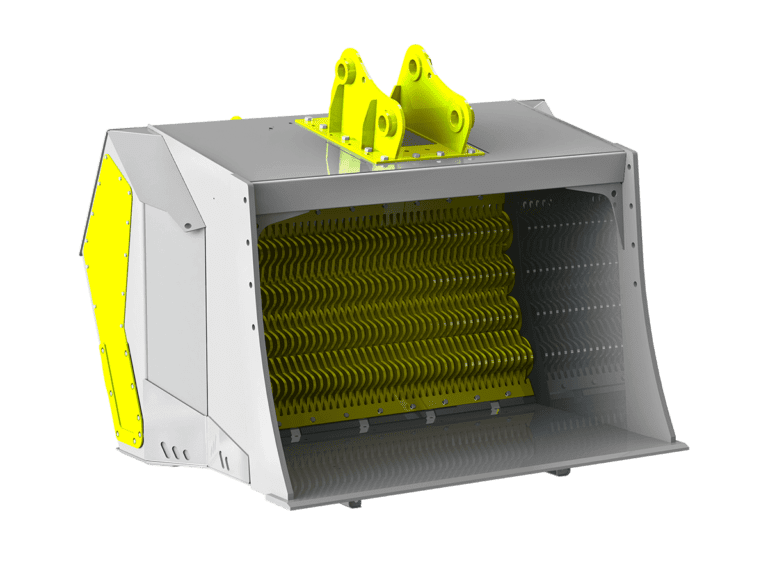

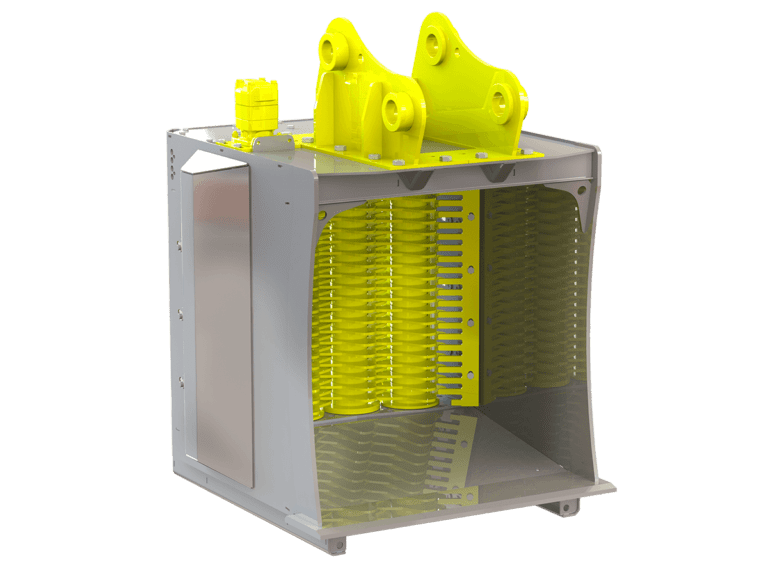

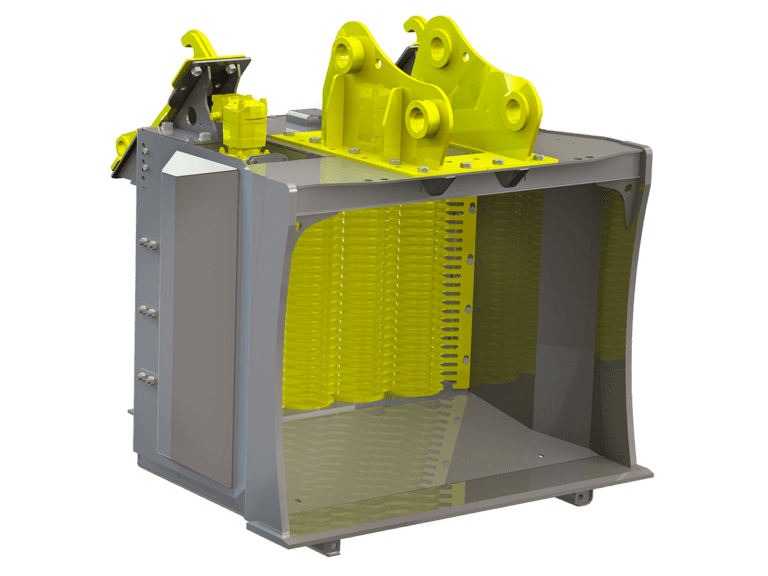

VPH 4-1502

Excavators: 14000-23000

Wheel loaders: 9000-15000

VPH 4-1502 is an updated version of the legendary 4-1500 model. Suitable for a wide range of machine sizes, both loaders and excavators. Available in a broad selection of optimized versions for fine screening, aeration, mixing, and light crushing.

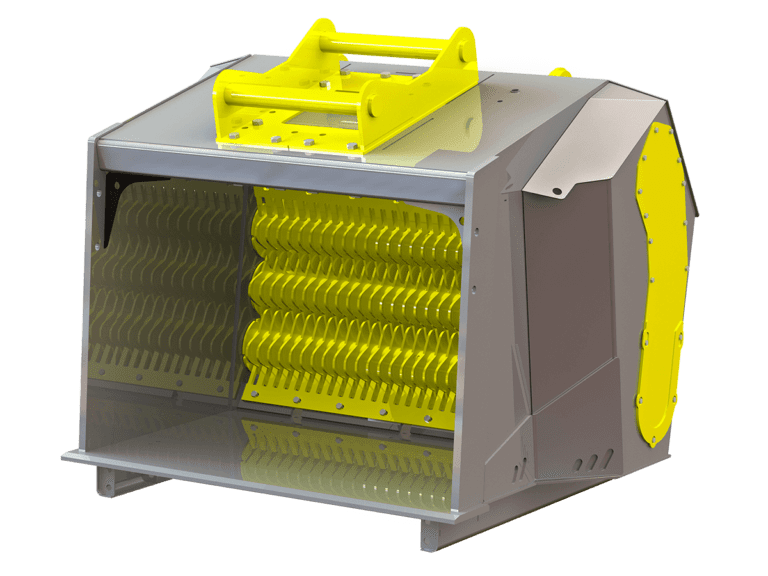

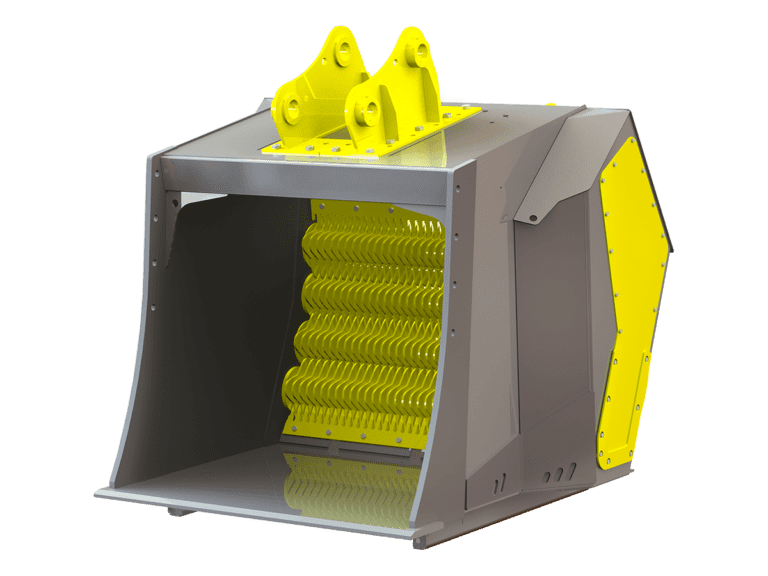

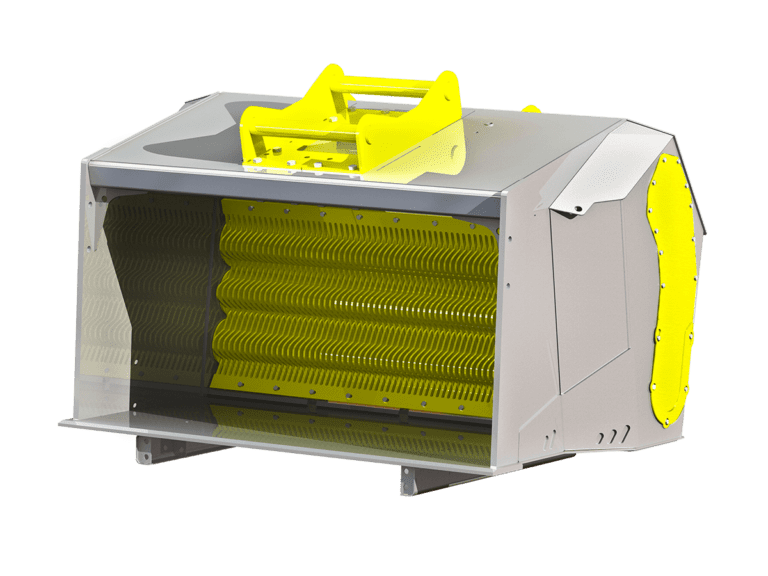

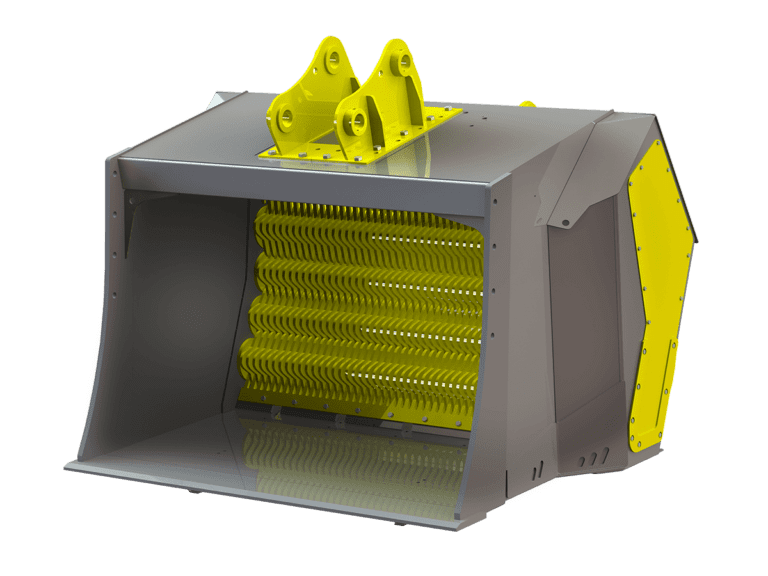

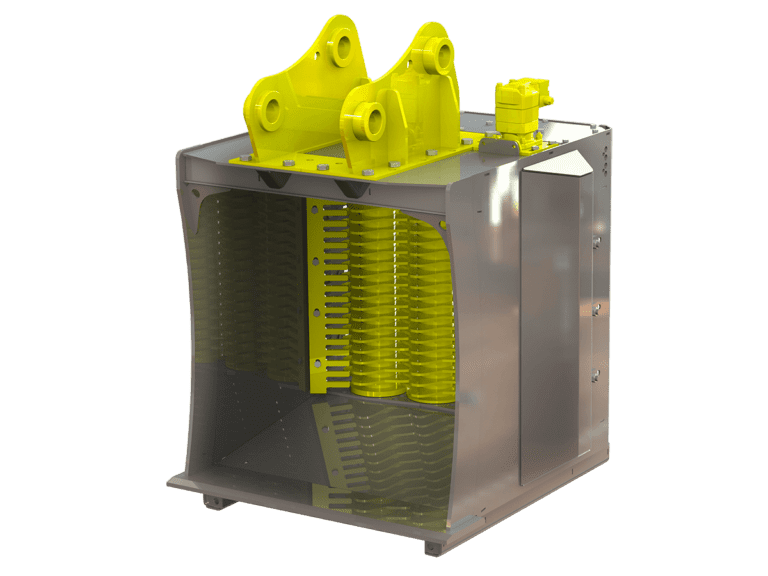

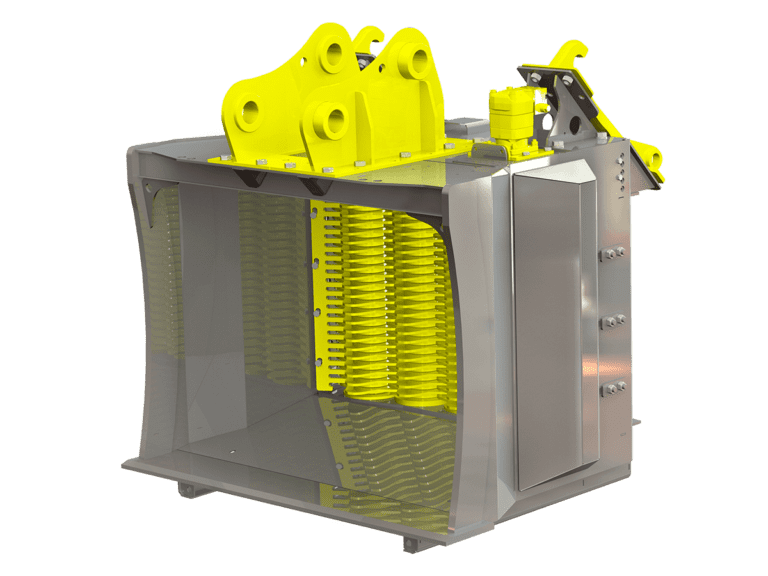

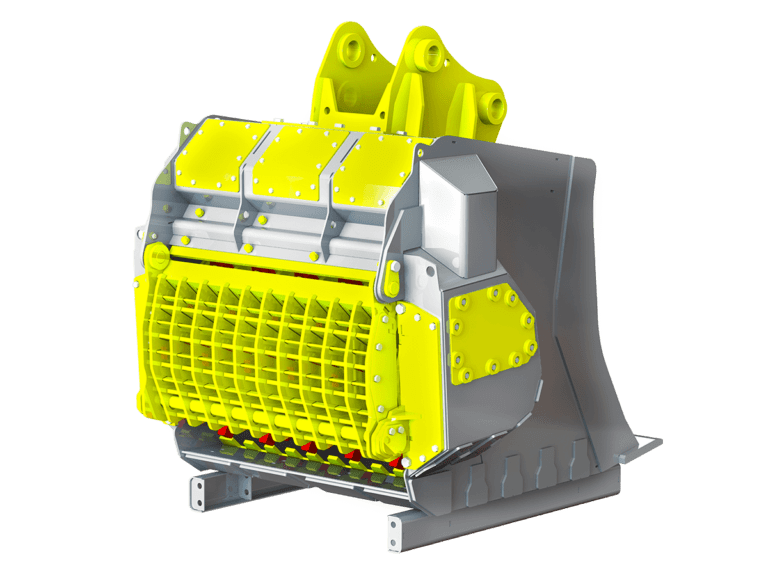

Read moreVPH 3-1700

Excavators: 22000-30000

Wheel loaders: 12000-16000

VPH 3-1700 is a robust and powerful screening bucket model favored by professionals. The model also offers versatile versions for fine screening, coarse screening, and even crushing.

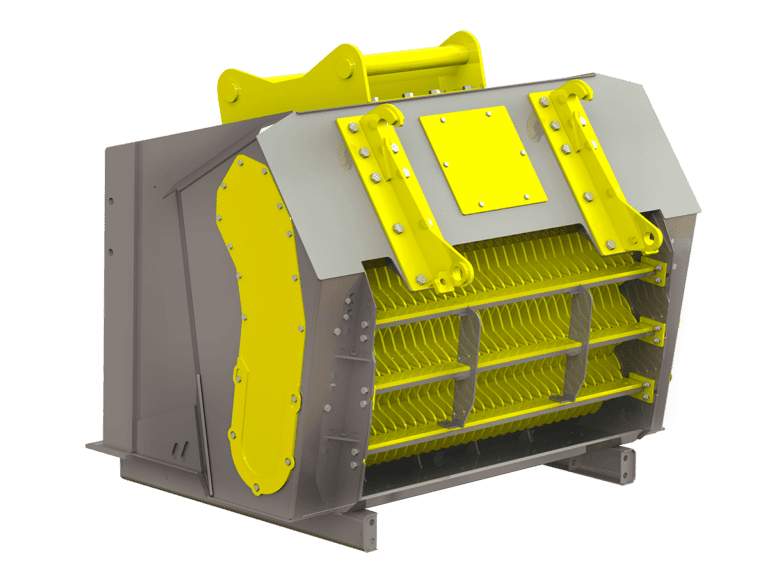

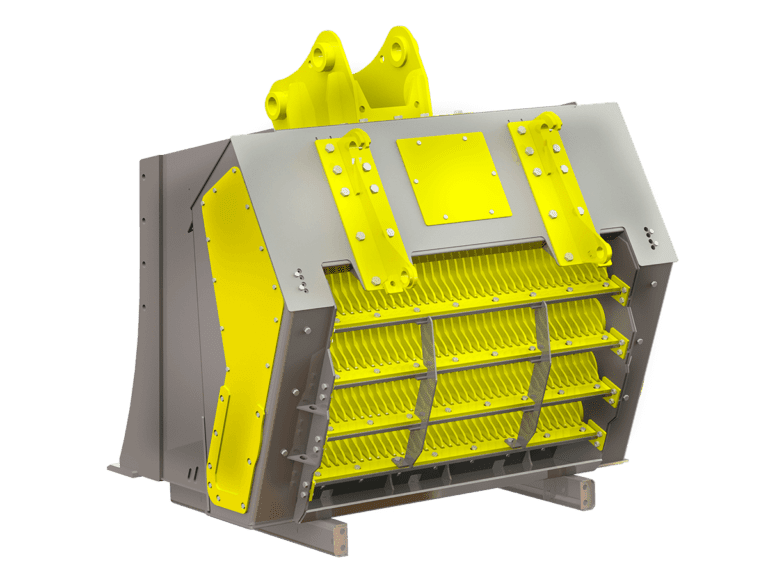

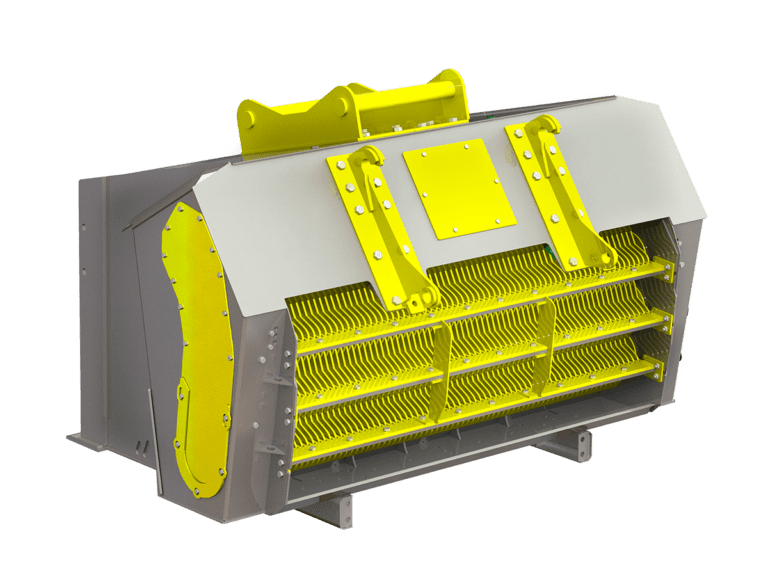

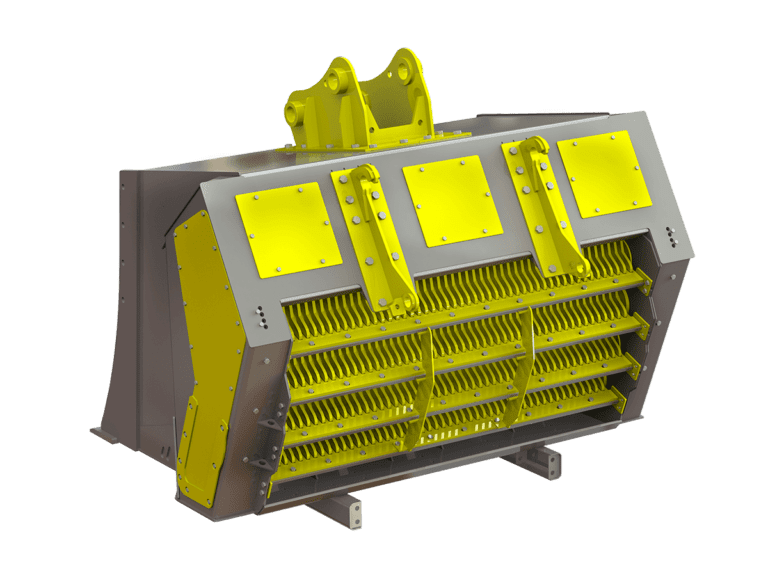

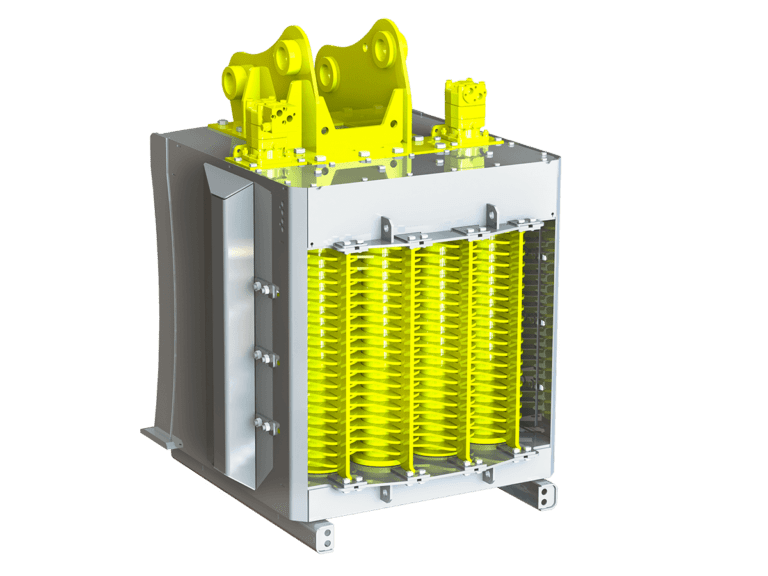

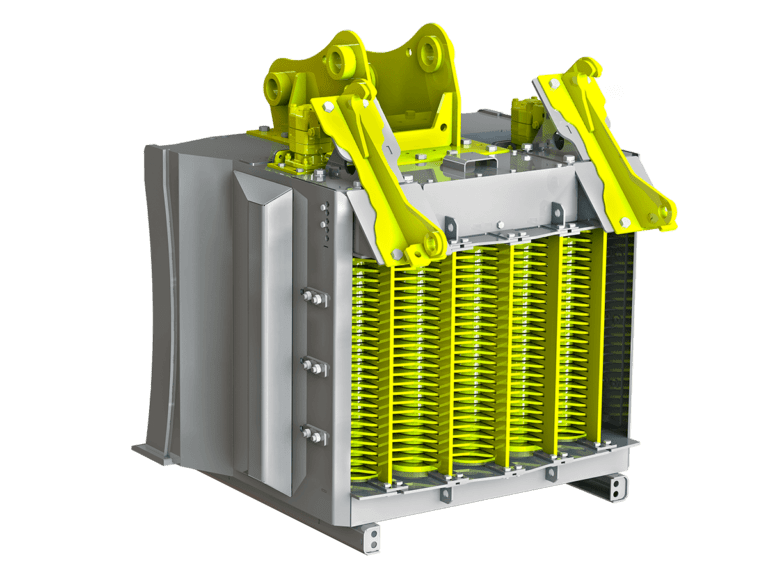

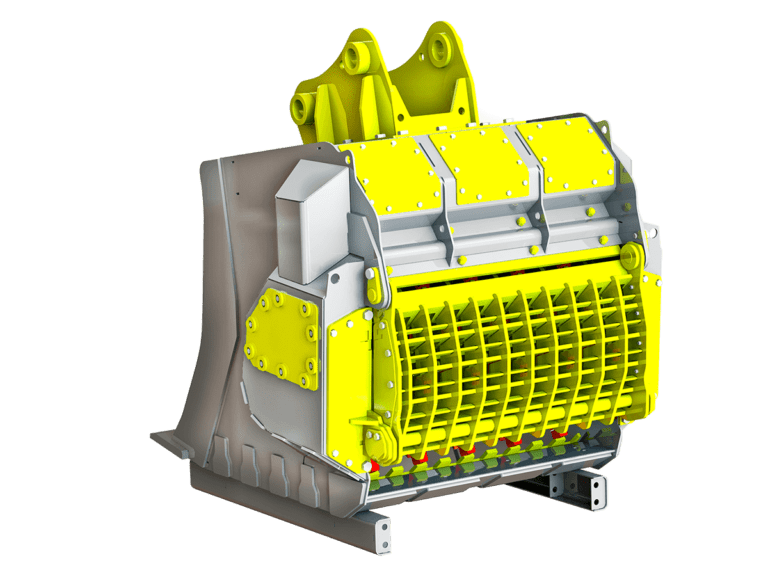

Read moreVPH 4-1700

Excavators: 24000-35000

Wheel loaders: 14000-20000

VPH 4-1700 is the big brother of the 3-1700 screening bucket model with four horizontal rotors for larger machine sizes. There are also several customized versions available for screening and crushing based on specific use cases.

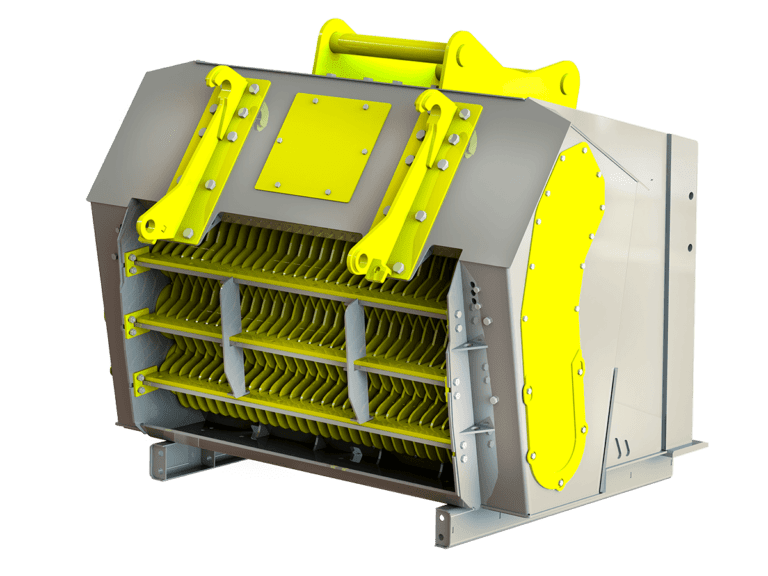

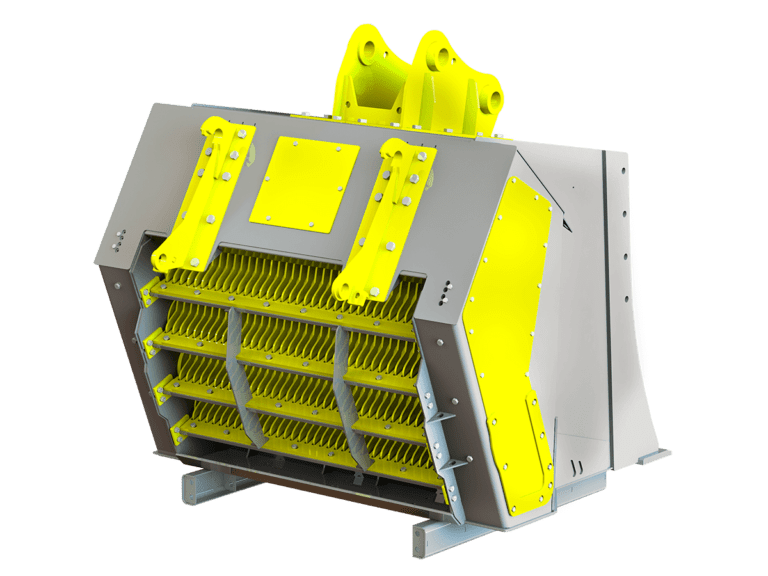

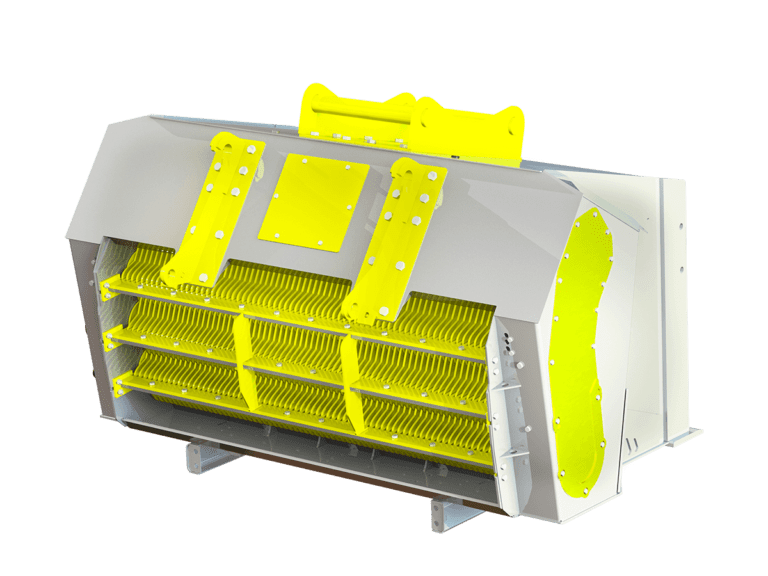

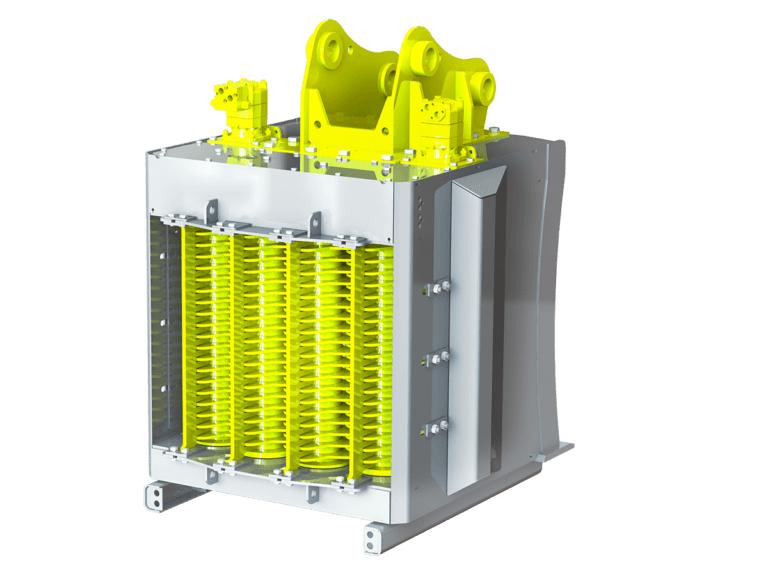

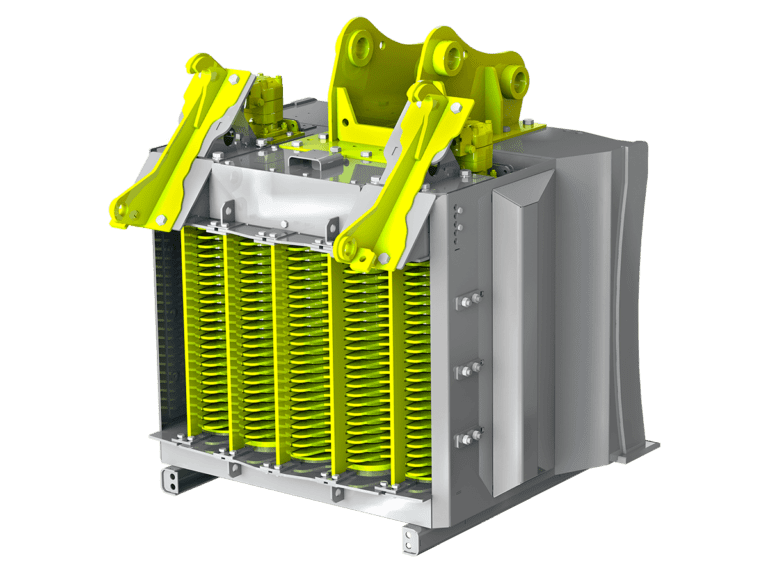

Read moreVPH 3-2300

Excavators: 28000-35000

Wheel loaders: 18000-25000

VPH 3-2300 is a high-capacity screening bucket for wheel loaders and excavators. Its versatile applications include widely used screening and mixing of materials such as peat, aggregates, and biomaterials.

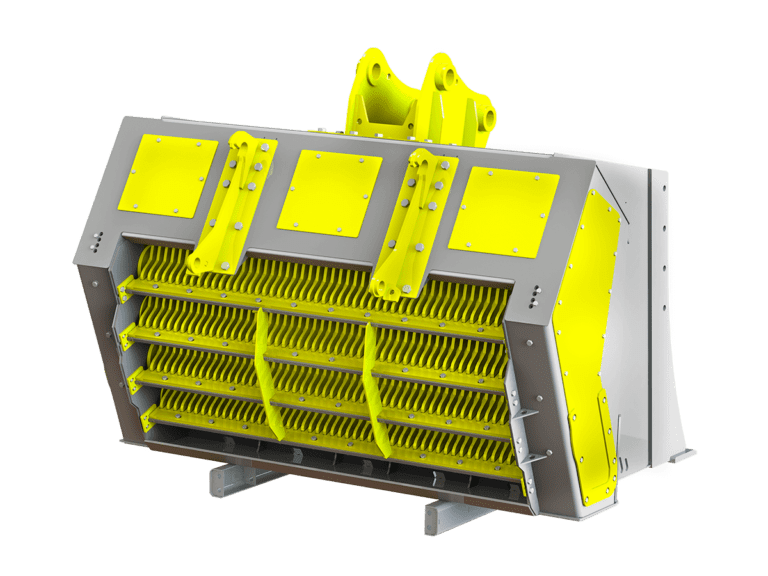

Read moreVPH 4-2300

Excavators: 32000-45000

Wheel loaders: 21000-30000

VPH 4-2300 is the flagship of the Viper screening bucket range. A powerful, high-capacity screening bucket designed for screening large volumes. With additional sides, the bucket volume can reach up to 5600

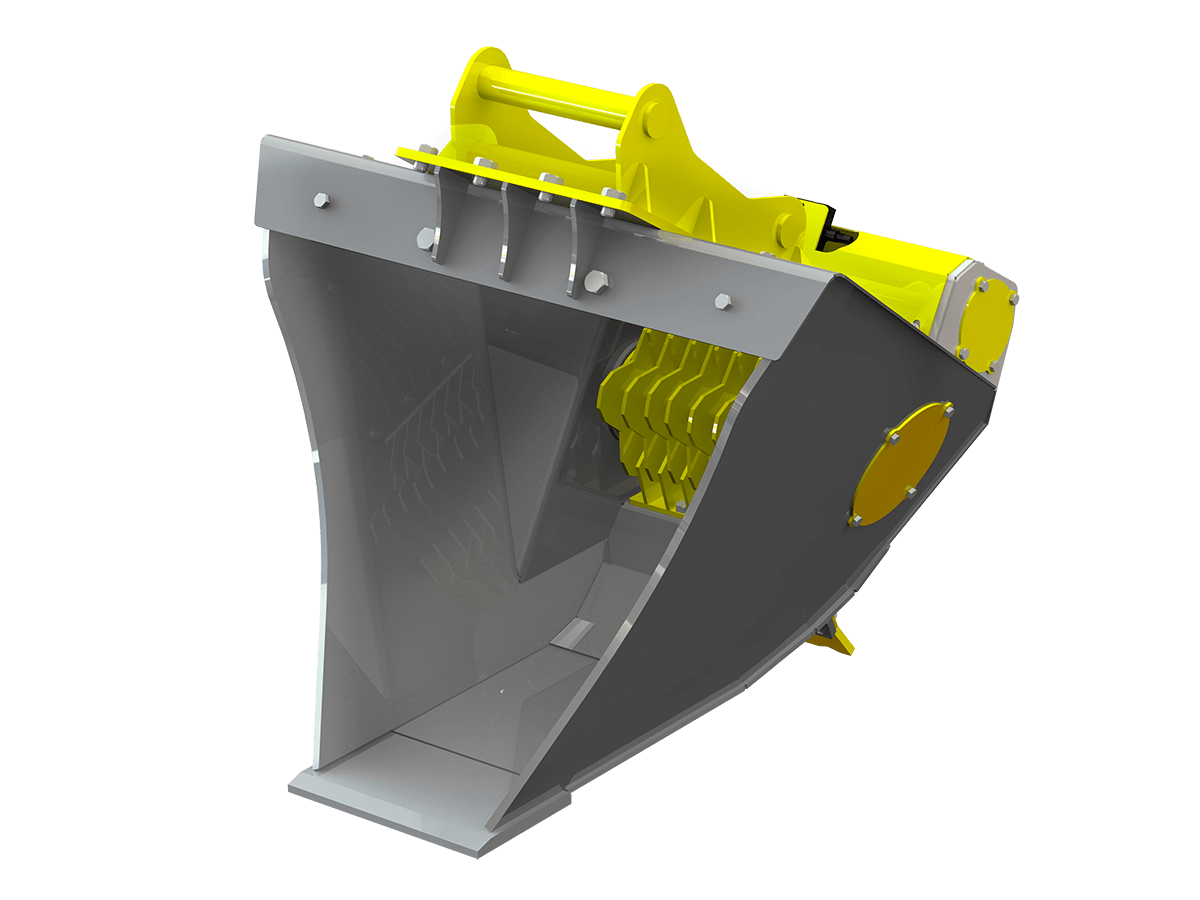

Read moreVPV 4-1100

Excavators: 14000-22000

VPV 4-1100 is a classic in the Vipermetal screening bucket range. This vertical drum model designed for excavators is an efficient and robust screening bucket for demanding use.

Read moreVPV 5-1350

Excavators: 20000-28000

Wheel loaders: 12000-16000

VPV 5-1350 is a vertical drum high-capacity screening bucket for various uses. Screening and crushing of aggregates are efficient with this bucket, favored by professionals.

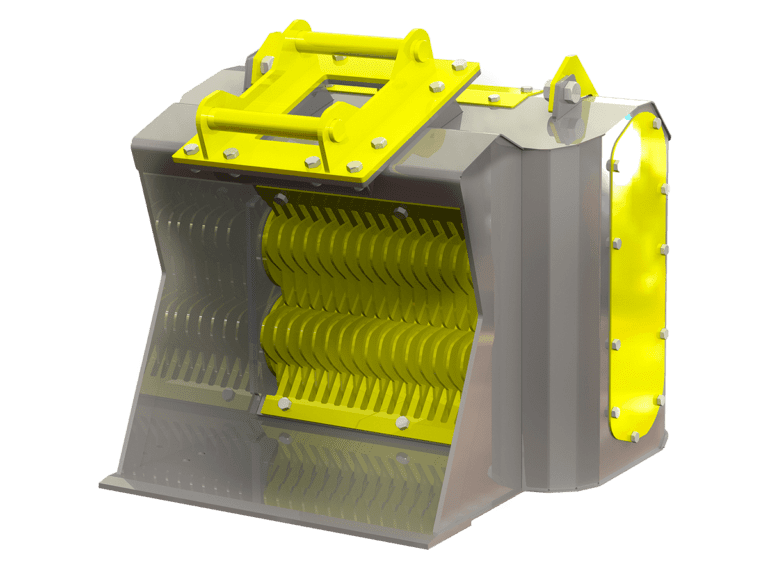

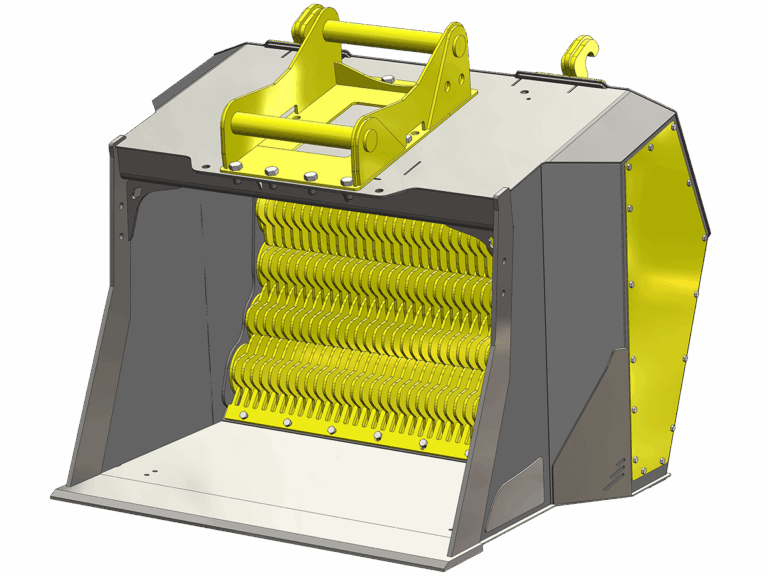

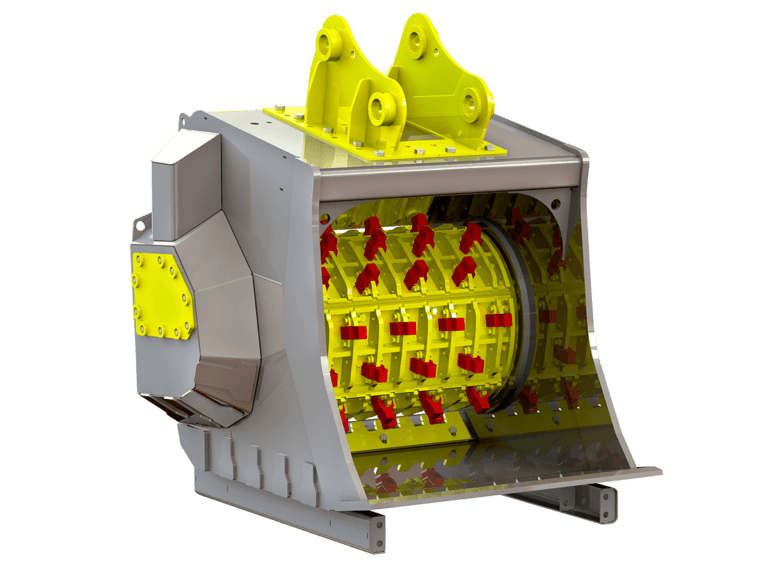

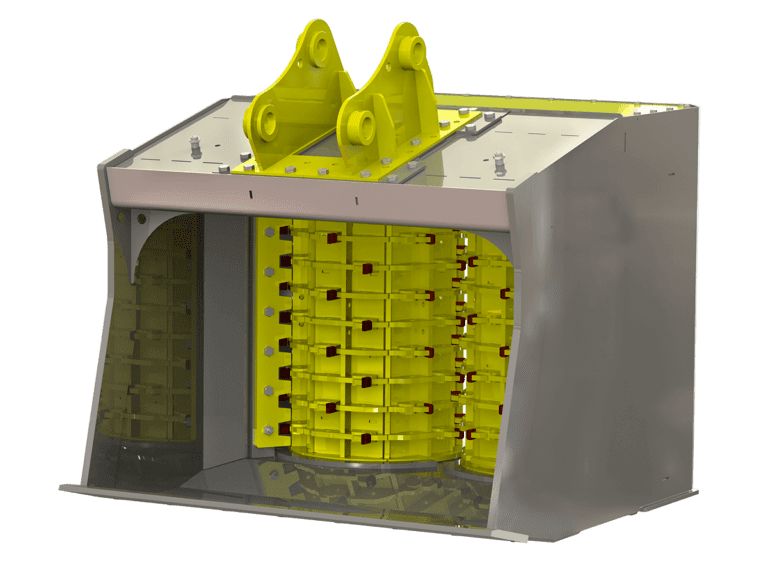

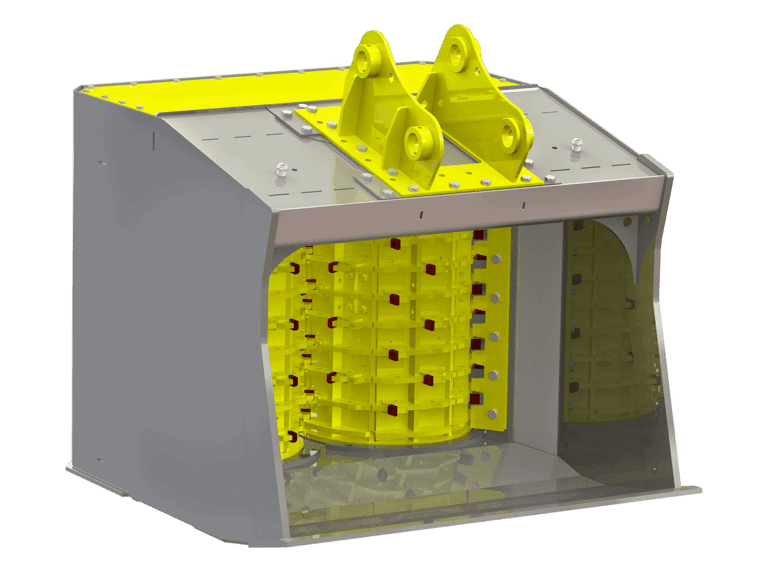

Read moreViper Crusher VPCH-21

Excavators 22000-32000

VPCH-21 is a unique drum crusher bucket. Efficient in crushing demolition materials. Crushes effectively, including concrete, asphalt, and bricks without the risk of clogging.

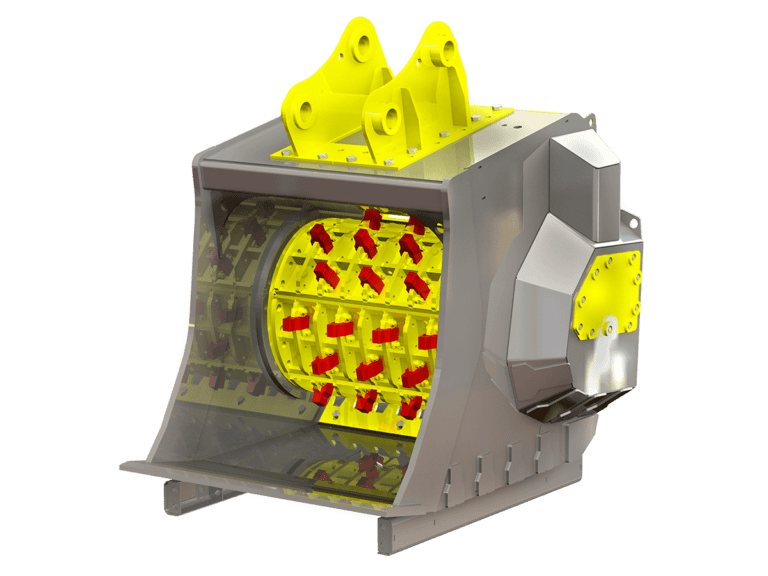

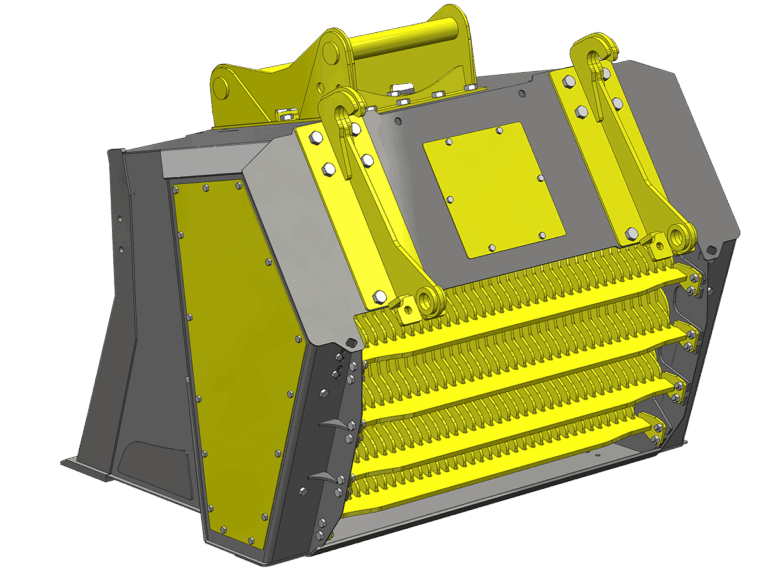

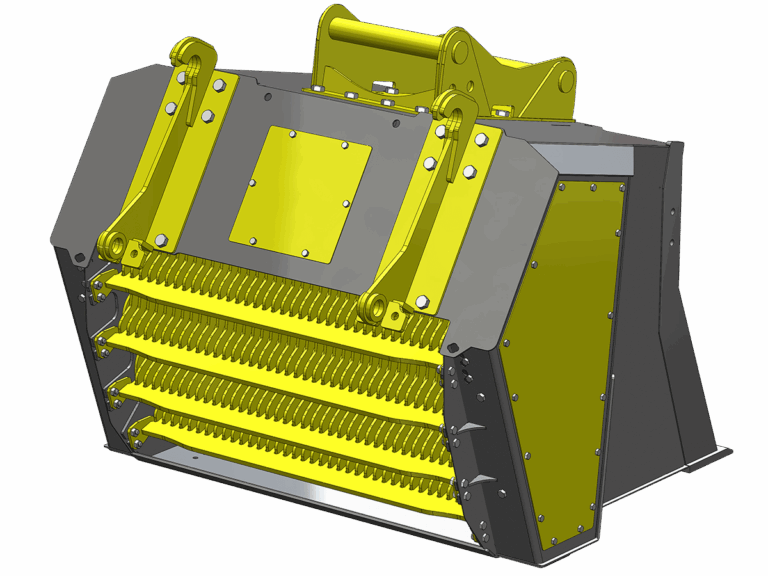

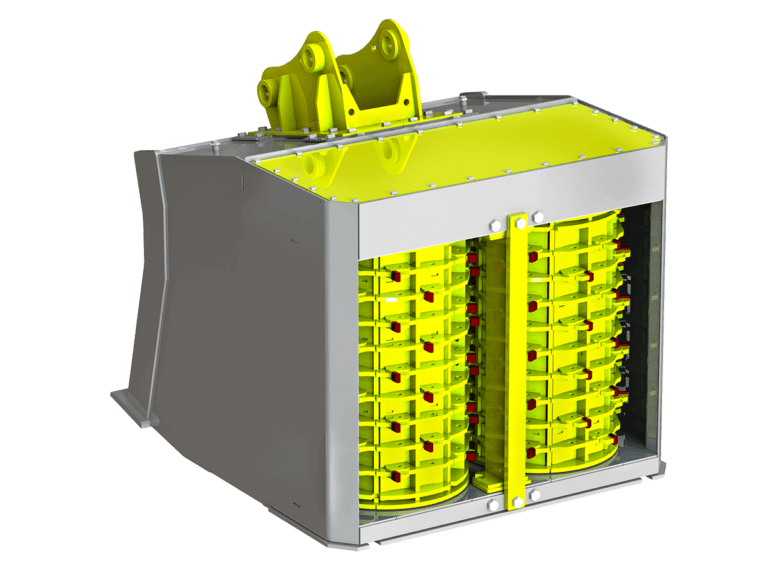

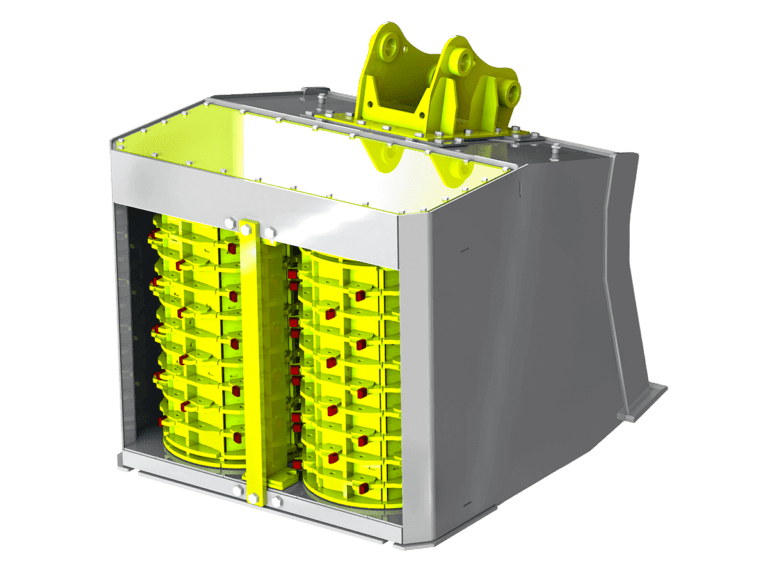

Read moreViper Crusher VPCV-22

Excavators 28000-40000

VPCV-22 is a modern, dual-drum, non-clogging crushing bucket designed for larger excavators. It’s commonly used, particularly in demolition sites, for the versatile crushing of concrete, asphalt, and mixed materials.

Read moreWould you like more information about our products?

We are more than happy to provide you with additional details about our products and help you find the best possible solution for any situation. Vipermetal’s services and solutions are designed to facilitate and enhance your material handling processes. Our goal is to offer you the best service tailored to meet your specific needs, whether it’s sales, resale, product advice, or exchange machines. You can rely on Vipermetal’s expertise and quality. Feel free to get in touch with us!